of the oil contamination and replace the desiccant cartridge.

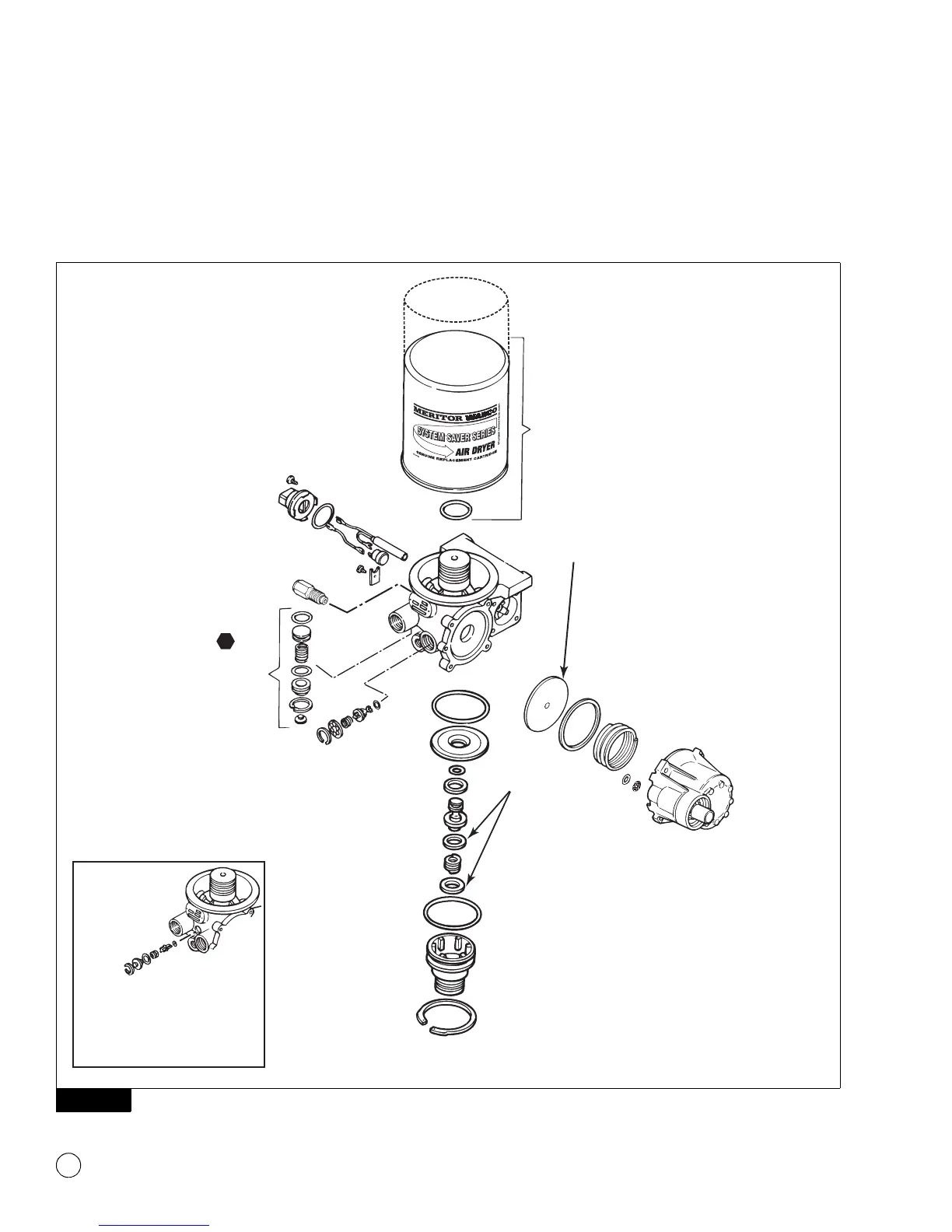

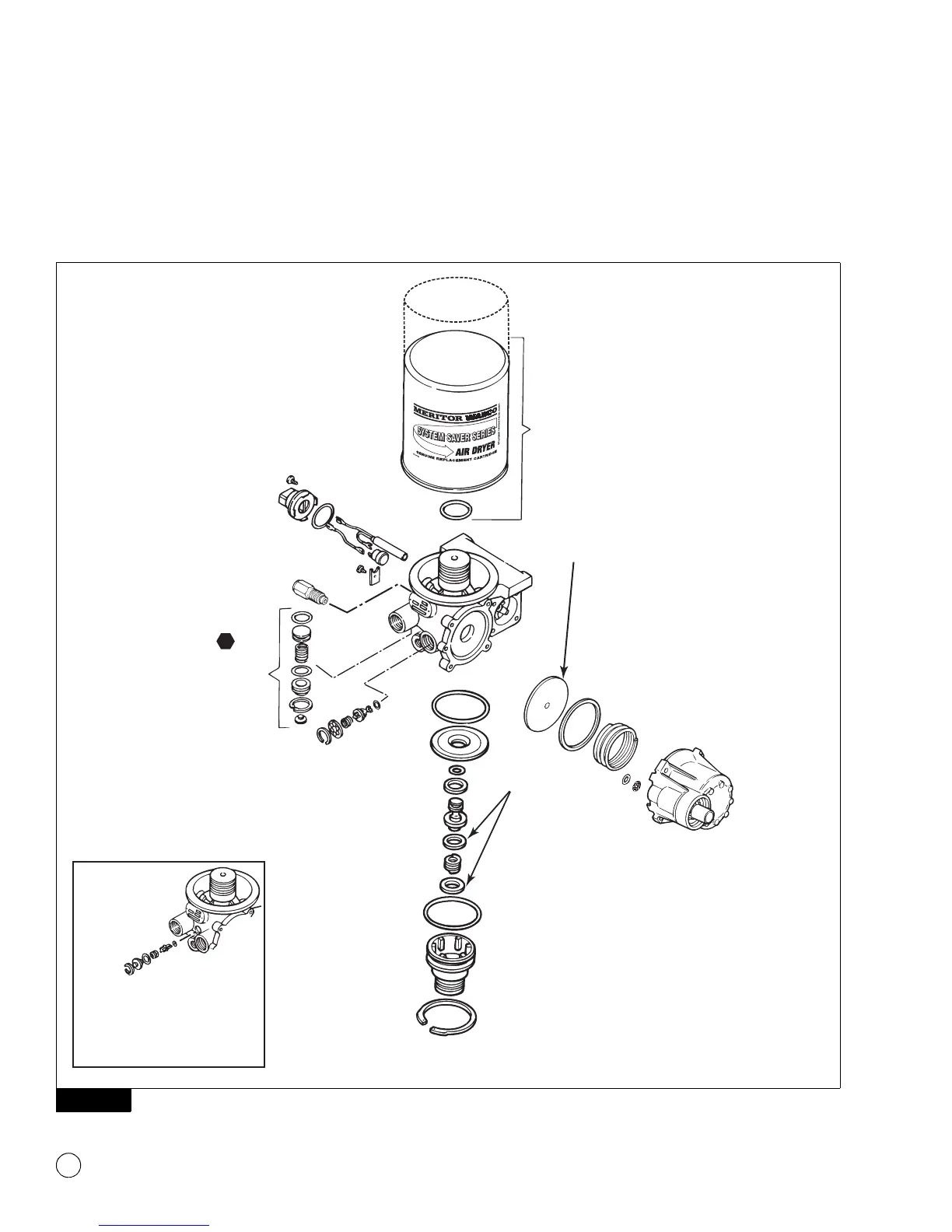

BYPASS VALVE

ASSEMBLY

Bypass valve is used on

dryers with date codes

earlier than 0894.

1002189a

O-Ring

Do not grease

diaphragm.

1200 Series air dryers do

not use bypass valve.

HEATER ASSEMBLY

• Disconnect plug.

• Remove old assembly.

• Install replacement element and

thermostat.

— Install retainer and screw to secure.

• Install replacement O-ring and receptacle.

— Fasten in place with screws.

Refer to Section 3 for more

detailed instructions.

DESICCANT CARTRIDGE

• Remove old cartridge.

• Lube and install O-ring.

• Install replacement cartridge.

T

PRESSURE RELIEF VALVE

• Unscrew and remove

old valve.

• Screw replacement

valve into dryer or

Street-Tee fitting.

• Do not exceed

recommended torque.

Refer to Pressure Relief

Valve in Section 3.

REGENERATION

VALVE ASSEMBLY —

REGENERATION STYLE

DRYERS ONLY

• Remove old assembly and

diaphragm.

• Clean diaphragm lip groove.

• Install replacement

diaphragm and assembly.

PURGE VALVE ASSEMBLY

• Remove old assembly.

• Clean valve bore.

• Grease valve bore.

• Install replacement assembly.

*

E Series dryers use a different style turbo

cut-off valve (Refer to Parts Book PB-96134).

**

Spring not used with U Series dryers.

NOTE: If shims are included in the

replacement kit, install one above

and one below the spring.

OUTLET CHECK

VALVE ASSEMBLY

• Remove old

assembly.

• Clean valve bore.

• Install replacement

O-ring in bore.

Then, grease O-ring

and bore.

TURBO CUT-OFF

VALVE ASSEMBLY

*

• Remove snap ring.

• Use needle nose pliers

to remove the piston.

• Clean bore (if bore is

badly damaged,

replace the air dryer).

• Install replacement

assembly.

* *

1800

1200

SHIMS

(IF REQUIRED)

Loading...

Loading...