Wagner Project 115 - 0418A

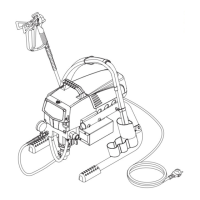

Assembly

Figure 2 - Assembling the Wheels

1. Slide the spacer (a), the wheel (b) and the push nut (c) over the

end of the axle in the order shown. Make sure the spacer (a) is

oriented so the lipped side will face toward the middle of the

axle.

You will need to stand the axle vertically on a at and

stable surface to assemble the wheels.

2. Lightlytaptheassemblyaid(d)withamallettosecurethe

push nut (c) over the end of the axle. Repeat steps for other

wheel.

Figure 3 - Assembling the Axle

1. Slide both ends of the axle up into the slots (a) as shown. The

lipped side of the spacers (b) should go inside of the axle

slots.

2. Make sure each axle plate is oriented and located as shown (L

and R). Secure each plate with two (2) screws. Snap the wheel

caps (e) over the ends of the push nuts.

Figure 4 - Assembling the Handle

1. To assemble the handle, press the button (a) as shown and

slidethehandleintothecartassembly.

2. Oncethehandleisfullyinsidethecart,releasethebuttonand

pull the handle until it locks in up or down position.

Figure 5 - Attaching the Hose

Make sure that the pump is switched o (position O) and

the spray device is disconnected from the power supply.

1. Screwthethreadofthehigh-pressurehoseontothespray

hose connection. Tighten with an adjustable wrench.

2. Threadtheotherendofthehosetothespraygun.

Gripthespraygunwithanadjustablewrenchonthehandle,

and tighten the hose nut with the other.

The spray tip should not be attached until after the

sprayer and spray hose have been purged and primed.

Before You Begin

Figure6-LockingtheSprayGun

Always lock the trigger o when attaching the spray

tip or when the spray gun is not in use.

1. The gun is secured when the trigger lock is at a 90° angle

(perpendicular) to the trigger in either direction.

Figure 7 - Pressure Relief Procedure

Be sure to follow the Pressure Relief Procedure when

shutting the unit o for any purpose.

This procedure relieves the pressure from the spray hose

and the gun.

1. Lockthesprayguno.FliptheON/OFFswitchtotheOFF

position.

2. Turn the PRIME/SPRAY knob to PRIME.

Take care not to pinch your ngers when turning the

switch.

3. Unlockthespraygunandtriggerspraygunintothesideof

thematerialbucket.Lockthespraygun.

Figure8-Removing/EmptyingtheHopper

Make sure your oors and furnishings are protected

with drop cloths to avoid property damage.

Always place the hopper on a hard, at, stable surface

when removed.

Perform the Pressure Relief Procedure (see gure 7) and

unplug the sprayer.

1. Perform Pressure Relief Procedure.

2. Pull the return tube (a) from the rear of the hopper lid.

3. Grabhopperbythesidehandles(b)andgentlypullitout.

4. Whennishedemptying/cleaning,replacehopperand

hopper lid.

5. Replacethereturntubebyinsertingitthroughthenotchin

the hopper lid.

The hopper can be heavy when lled with spraying

material. Make sure to lift with your legs and not

your back in order to reduce the risk of injury.

Purging and Priming

Figure9-PrimingtheSprayer

Make sure that the pump is switched o (position O) and

the spray device is disconnected from the power supply.

1. Pull the return tube from the hopper and hold it over a waste

container.

2. TurnthePRIME/SPRAYknobtoPRIME.Pluginthesprayer.

PresstheON/OFFswitchintotheONposition(I).

Any uids remaining in the pump and the return tube

will ow out of the return tube. Let the pump run until

no uid is coming from the return tube.

15

Coating Materials Not Suitable for Use

Materialsthatcontainhighlyabrasivecomponents,facadepaint,

caustic solutions and acidic coating substances.

Materials with a ash point below 21°C.

Inordertoensurecompatibilityofthecoatingsubstance

with the materials used to manufacture the device, please

contact Wagner Service in cases of doubt.

Field of application

Coating of interior walls as well as small and medium-sized objects

outdoors (e.g. garden fences, garage doors, etc.).

Industrial use is excluded.

Loading...

Loading...