resonance. The size should be based on a maximum

velocity of 30 ft/sec. Changes in direction must be as

slow as possible. Circular elbows should be of at least a

four piece construction with a centerline radius that is at

least double the duct diameter (use three times the duct

width for square ducts). The breeching should have a

slight upward elevation (about 1” per foot) towards the

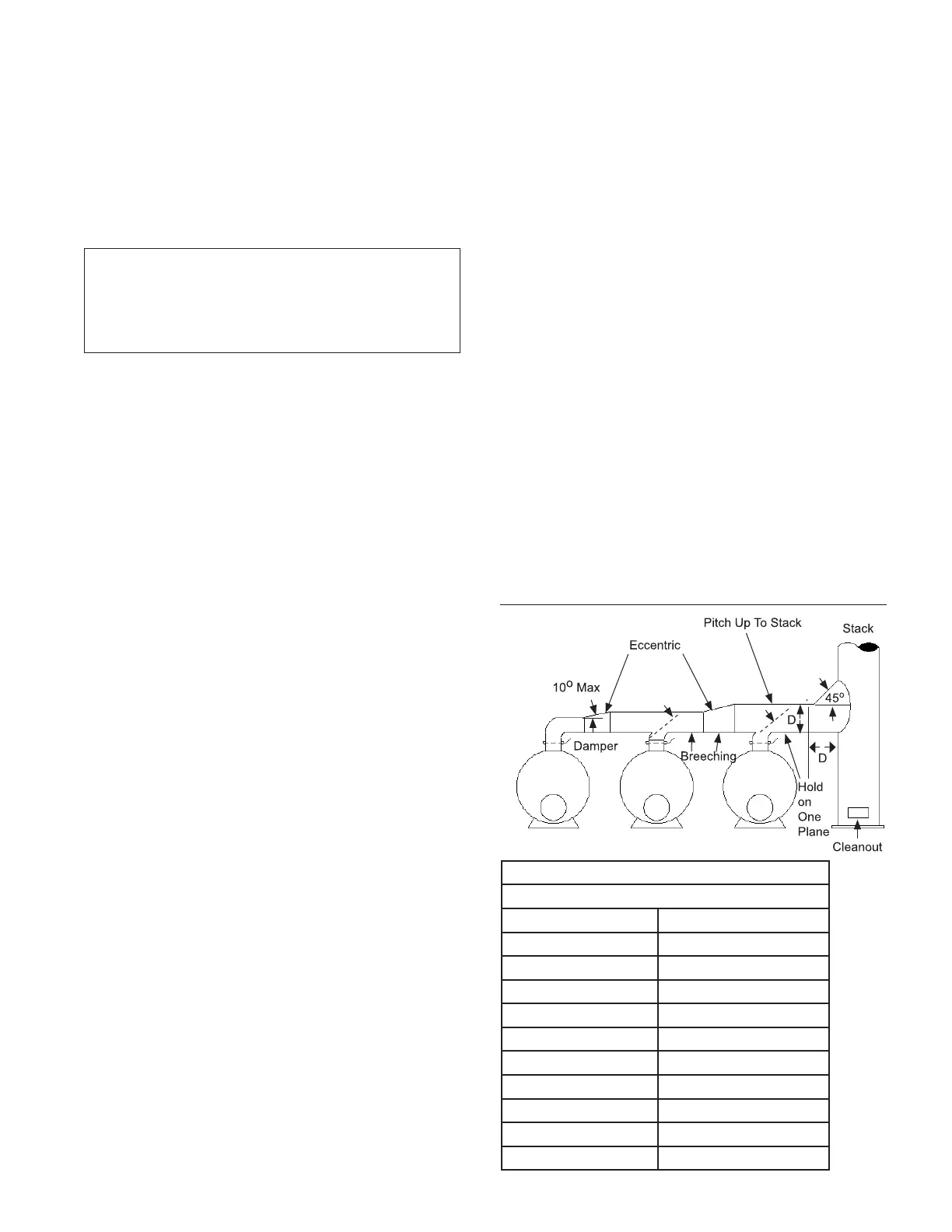

stack to help induce a draft. Figure C-15 shows the total

BHP that can be red within different breeching diam-

eters. These can be multiple boilers of different size.

CAUTION

OIL BURNING EQUIPMENT SHALL BE

CONNECTED TO FLUES HAVING SUFFICIENT

DRAFT AT ALL TIMES, TO ASSURE SAFE AND

PROPER OPERATION OF THE BURNER.

The connection of the breeching to the stack, or

multiple boilers to a common breeching or stack, must

be done with care. The ducts should never be

connected at a 90º angle, but at a 45º angle where the

ows will easily join each other. When connecting

multiple boilers to a single breeching, the breeching

size must be increased to accommodate the larger

ow rates before the added ow is introduced. These

size changes must be gradual, with no more then a 10º

slope change in the duct. When multiple breechings are

connected into a common stack, their locations must be

staggered to prevent the ow of one breeching interfer-

ing with another. Figure C-14 shows these guidelines.

Tall stacks can generate large drafts, and in fact the

amount of the draft is related to the stack height.

Systems with multiple boilers can have draft variations

that are well beyond the desired level. These conditions

must be corrected to allow the burner to work properly,

or the draft variations will cause combustion problems.

Controls can be added to compensate for this draft,

and bring it back to the desired level. The baromet-

ric damper is the most common and least expensive

control. Several barometric dampers can be added to

provide the total correction to the system draft.

Draft controls are also available to regulate the draft by

controlling an outlet damper. The speed of response is

critical to allow these units to work correctly. If the draft

control does not operate faster than the burner changes

rate, the result may be large swings in draft as the

control attempts to catch up with the burner. A feed for-

ward control is the best means of achieving this. If there

are large drafts due to tall buildings, special

consideration must be given to the type of damper

needed to regulate this draft, and the response of the

control to maintain the proper draft.

11. Electrical System

The burner is supplied as standard, with a control panel.

The panel can be integral to the burner or remote for

oor or wall mounting. The proper location will allow the

operator to see the burner operate while manning the

controls. In some areas, there are local regulations that

dene where the control panel must be mounted

The remote control panel must be securely attached to

either the oor or the wall. This should include lag bolts.

The wiring diagram for the specic job should be

followed for connections to the panels and external

equipment. The National Electric Code, Canadian

Electrical Code, Part 1 or similar code for other

jurisdictions should be followed.

The following list covers the standard acronyms:

AUX. – Auxiliary

CB – Circuit Breaker

C.C.W. – Counter Clock-Wise

C.W. – Clock-Wise

CR( ) – Control Relay

FGR – Flue Gas Recirculation

FTS – Fuel Transfer Switch

GND – Ground terminal

H.W.C.O. – High Water Cut Off

INT – Interlock

L – 120V line

L.F.H. – Low Fire Hold switch

L.W.C.O. – Low Water Cut Off

MR – Manual Reset

N. – 120 V Neutral

N.C. – Normally Closed

N.O. – Normally Open

P.L.F.S. – Proven Low Fire Start

P.O.C.S. – Proof Of Closure Switch

SW. – Switch

TDR – Time Delay Relay

JBE(X) Manual

Section C - Installation

Page 27

45

o

o

Figure C14 - Method

of Connecting

Breechings and

Stacks

Figure C-15

Maximum Boiler HP in Breeching

Breeching Dia. (in) Total Max Boiler HP

16 200

18 300

20 400

22 500

24 700

26 900

28 1100

30 1400

32 1600

34 1900

Loading...

Loading...