i

2 550-142-301/0123

1

2

3

4

5

6

7

8

SECTION 1

–

SAFETY 3

Safety Signals . . . . . . . . . . . . . . . . . . . . . . 3

Please Read Before Proceeding . . . . . . . . . . . . 3

Boiler Maintenance . . . . . . . . . . . . . . . . . . . . . . .3

Safe Boiler Operation. . . . . . . . . . . . . . . . . . . . . .4

Boiler Water . . . . . . . . . . . . . . . . . . . . . . . . . .4

Frozen Water Damage . . . . . . . . . . . . . . . . . . . . .4

Damage from Water Contact . . . . . . . . . . . . . . . . . .4

SECTION 2

–

OPERATION 5

Operating the Boiler. . . . . . . . . . . . . . . . . . . 5

Prevent Combustion Air Contamination . . . . . . . . . . . .5

Operating Instructions . . . . . . . . . . . . . . . . . . . . .5

CGa, EG-30 to EG-75, PEG-30 to PEG-55 . . . . . . . . . .6

CGa-25 to CGa-6, EG-30 to EG-50, PEG-30 to PEG-50 . . .7

CGa-7, CGa-8, EG-55 to EG-75, PEG-55 . . . . . . . . . . .8

CGa-25 to CGa-6, EG-30 to EG-50, PEG-30 to PEG-50 . . .9

CGi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

LGB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Troubleshooting . . . . . . . . . . . . . . . . . . . . 12

Common Issues and Solutions . . . . . . . . . . . . . . . . 12

SECTION 3

–

MAINTENANCE 13

Maintenance Overview . . . . . . . . . . . . . . . . 13

Servicing and Maintaining the Boiler . . . . . . . . . . . . .13

Boiler Components . . . . . . . . . . . . . . . . . . 14

Tankless Water Heater (EG and PEG only) . . . . . . . . . 14

Rollout Thermal Fuse Element (CGa, CGi, EG, & PEG only) . .14

Spill Switch (CGa, EG, & PEG only). . . . . . . . . . . . . 14

Pressure Switch (LGB only) . . . . . . . . . . . . . . . . . 14

CGa Series 3 . . . . . . . . . . . . . . . . . . . . . . . . . 15

CGi Series 4 . . . . . . . . . . . . . . . . . . . . . . . . . 16

EG/PEG . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LGB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance Procedures — DAILY. . . . . . . . . . 18

Boiler Area . . . . . . . . . . . . . . . . . . . . . . . . . .18

Pressure/Temperature Gauge or Pressure Gauge (Steam) . 18

Air openings . . . . . . . . . . . . . . . . . . . . . . . . . 18

Maintenance Procedures — MONTHLY . . . . . . . 19

Boiler Piping . . . . . . . . . . . . . . . . . . . . . . . . . 19

Venting System . . . . . . . . . . . . . . . . . . . . . . . . 19

Boiler Relief Valve . . . . . . . . . . . . . . . . . . . . . . 19

Automatic Air Vents (if used) . . . . . . . . . . . . . . . . .19

Pilot Burner Flame . . . . . . . . . . . . . . . . . . . . . .20

Main Burner Flame . . . . . . . . . . . . . . . . . . . . . . 20

Check Condensate Drain System (if used). . . . . . . . . . 20

Maintenance Procedures — PERIODICALLY . . . . 21

Test the Low Water Cuto . . . . . . . . . . . . . . . . . . 21

Float Type Low Water Cuto . . . . . . . . . . . . . . . . .21

Probe Type Low Water Cuto . . . . . . . . . . . . . . . . 21

Integrated Type Low Water Cuto . . . . . . . . . . . . . .22

Clean Gauge Glass. . . . . . . . . . . . . . . . . . . . . . 22

Oil Inducer Motor (CGi Boilers). . . . . . . . . . . . . . . . 22

Maintenance Procedures — EVERY 6 MONTHS. . . 23

Operate the Boiler Relief Valve. . . . . . . . . . . . . . . . 23

Maintenance Procedures — END OF SEASON . . . 23

Boiler Shutdown Procedure . . . . . . . . . . . . . . . . . 23

Propane Gas Odorant . . . . . . . . . . . . . . . . . . . . 23

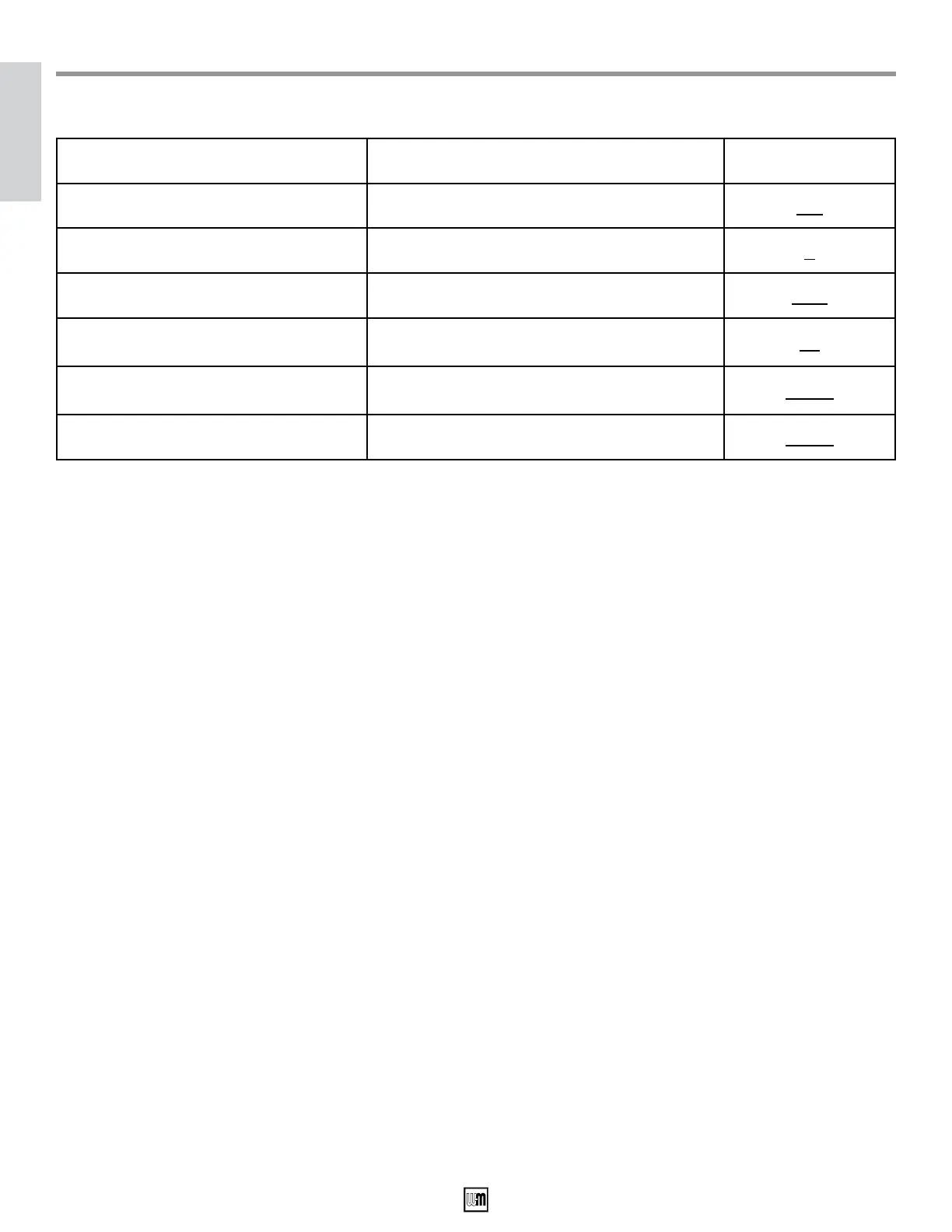

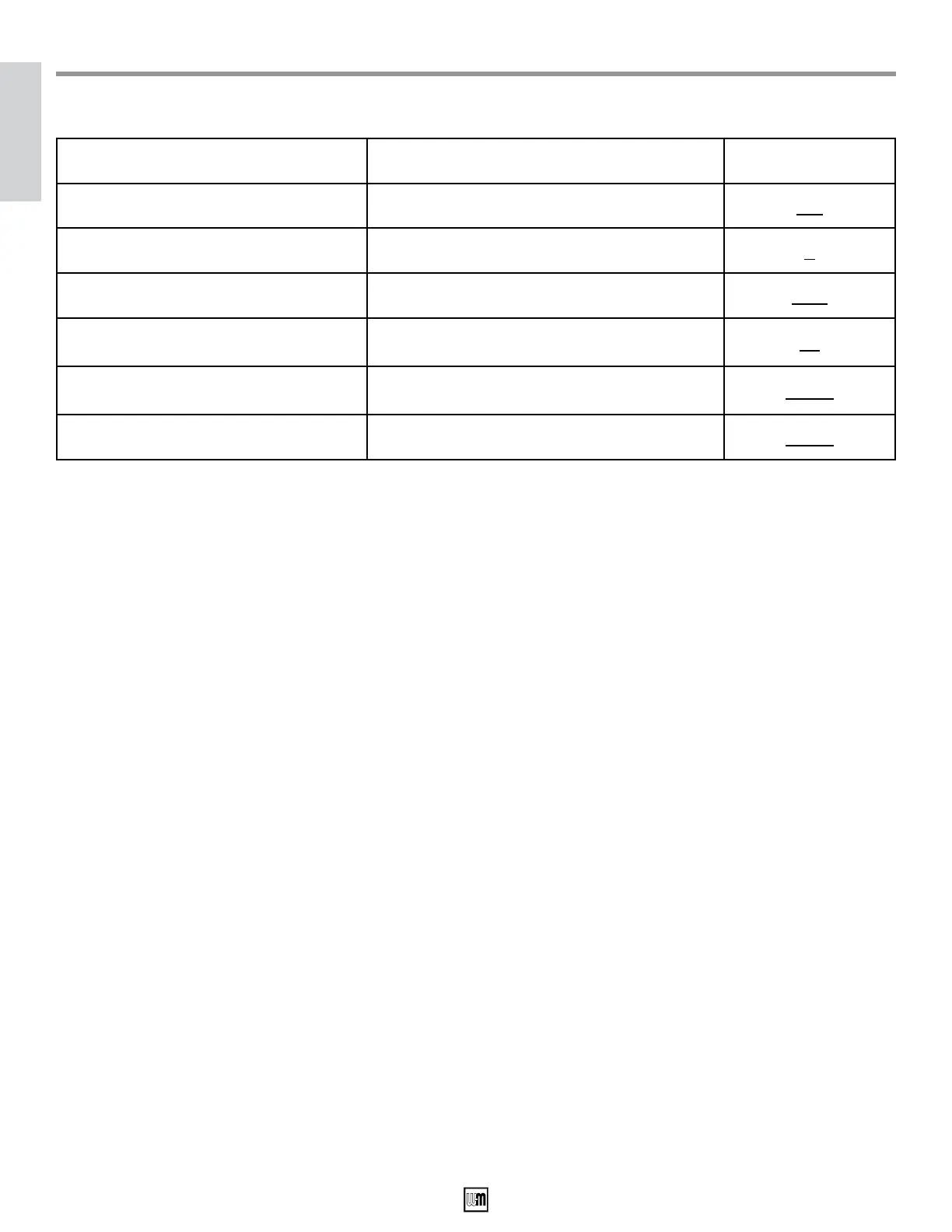

How to Use This Manual

Contents

To do the following: Read and Use: Page(s)

Learn precautions Safety warnings and information 3-4

Prevent air contamination List of air contaminants to avoid 5

Start or shut down the boiler Operating instructions 6-11

Troubleshoot common issues

Use the troubleshooting table to resolve

typical heating system and boiler issues.

12

Identify and locate boiler

components

Boiler illustrations

14-17

Maintain the boiler Boiler maintenance schedules

18-23

Draft - For Engineering Review ONLY Jan. 2023 HC

Loading...

Loading...