i

22 550-142-301/0123

1

2

3

4

5

6

7

8

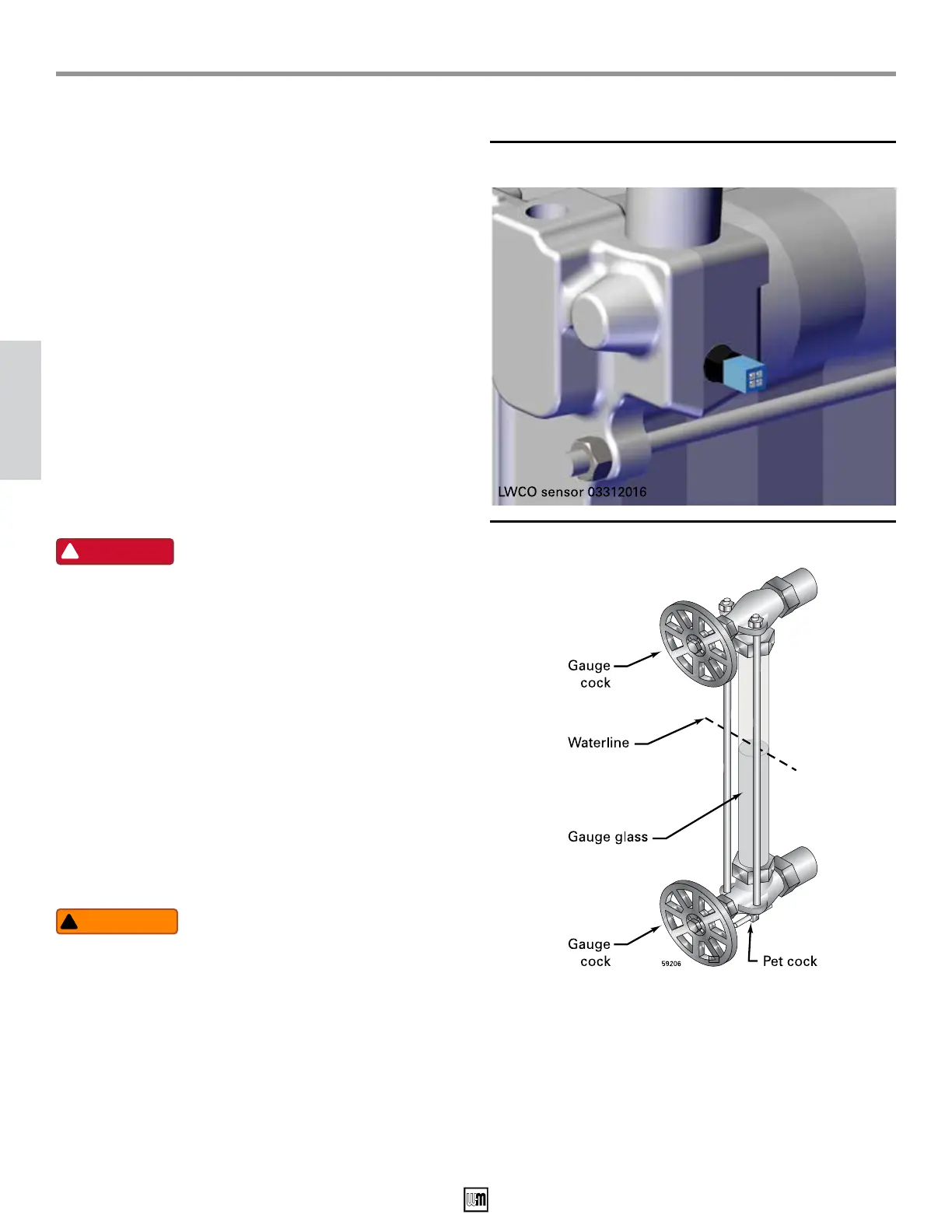

Integrated Type Low Water Cuto

1. Test LWCO using control LWCO TEST button.

a. During burner re, press LWCO TEST button.

b. Burner should shut o.

2. Clean periodically (when warning occurs).

a. Turn o power to boiler and wait 5 minutes.

b. Drain boiler to empty.

c. Remove sensor, wipe clean. See Figure 11.

d. Reinstall sensor to specied 18 ft/lbs torque.

e. Rell boiler to pressure, purge air.

f. Turn on boiler power.

g. Ensure proper operation resumes.

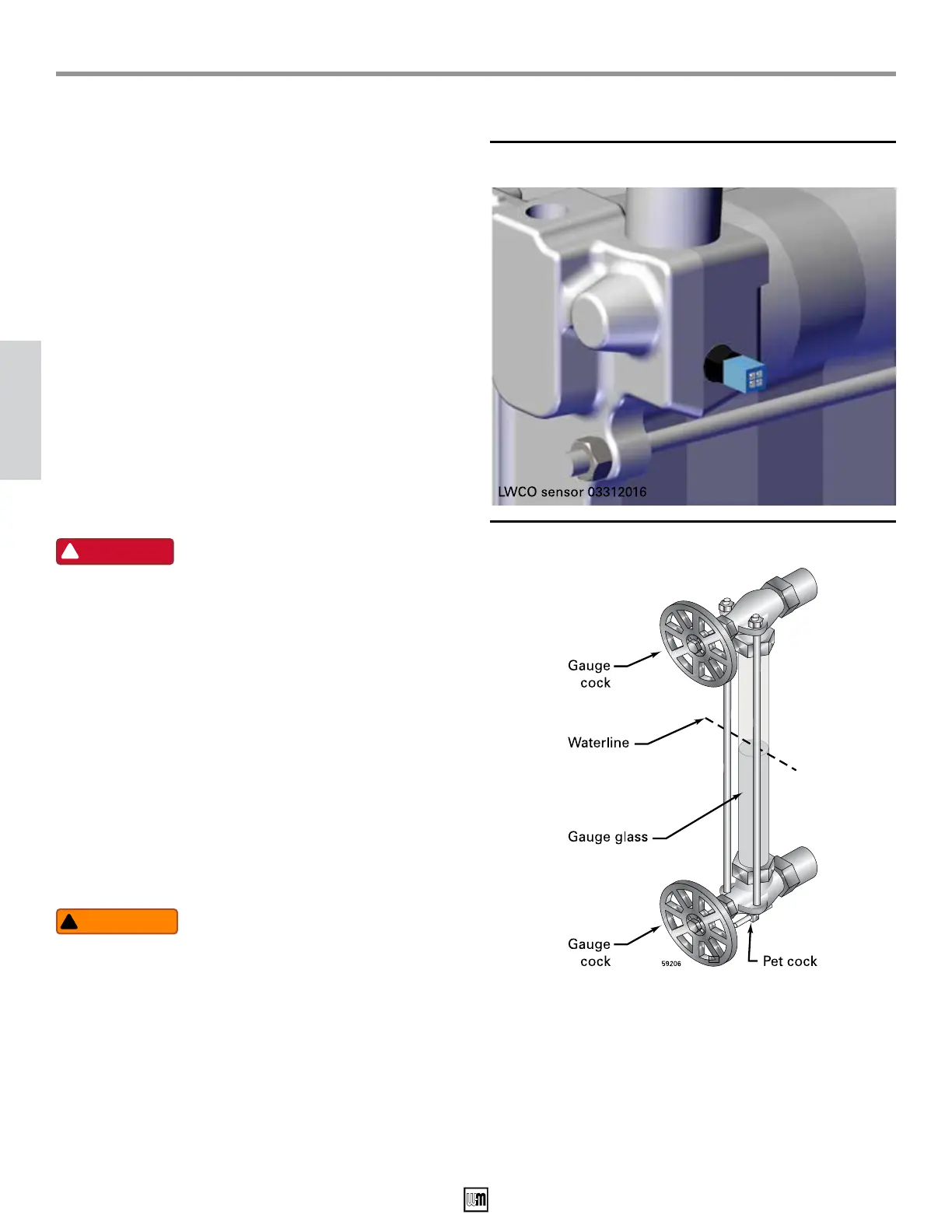

Clean Gauge Glass

Normal waterline on a steam boiler is halfway up

gauge glass. See Figure 12. Clean when needed.

!

Boiler pressure must be low to eliminate potential

of severe burns.

1. Close lower gauge cock.

2. Open pet cock.

3. Open lower gauge cock and allow a small amount

of water to ush out through open pet cock.

4. Close pet cock.

5. Open lower gauge cock.

6. If gauge glass breaks, close both gauge cocks

and call a qualied service technician to replace

gauge glass. Do not replace with thin glass

tubing.

Oil Inducer Motor (CGi Boilers)

!

Use only SAE 20 motor oil to lubricate the

inducer motor. Do not use common universal

household oils.

1. Use only SAE 20 motor oil. DO NOT use

household universal oils.

2. Place a few drops of oil in each of the two oiler

cups on the inducer motor.

Maintenance Procedures — PERIODICALLY, continued

Draft - For Engineering Review ONLY Jan. 2023 HC

Figure 11 Integrated type low water cuto

Figure 12 Gauge glass

Loading...

Loading...