en

Installation and operating instructions • Wilo-Control EC-L • Ed.04/2022-09 57

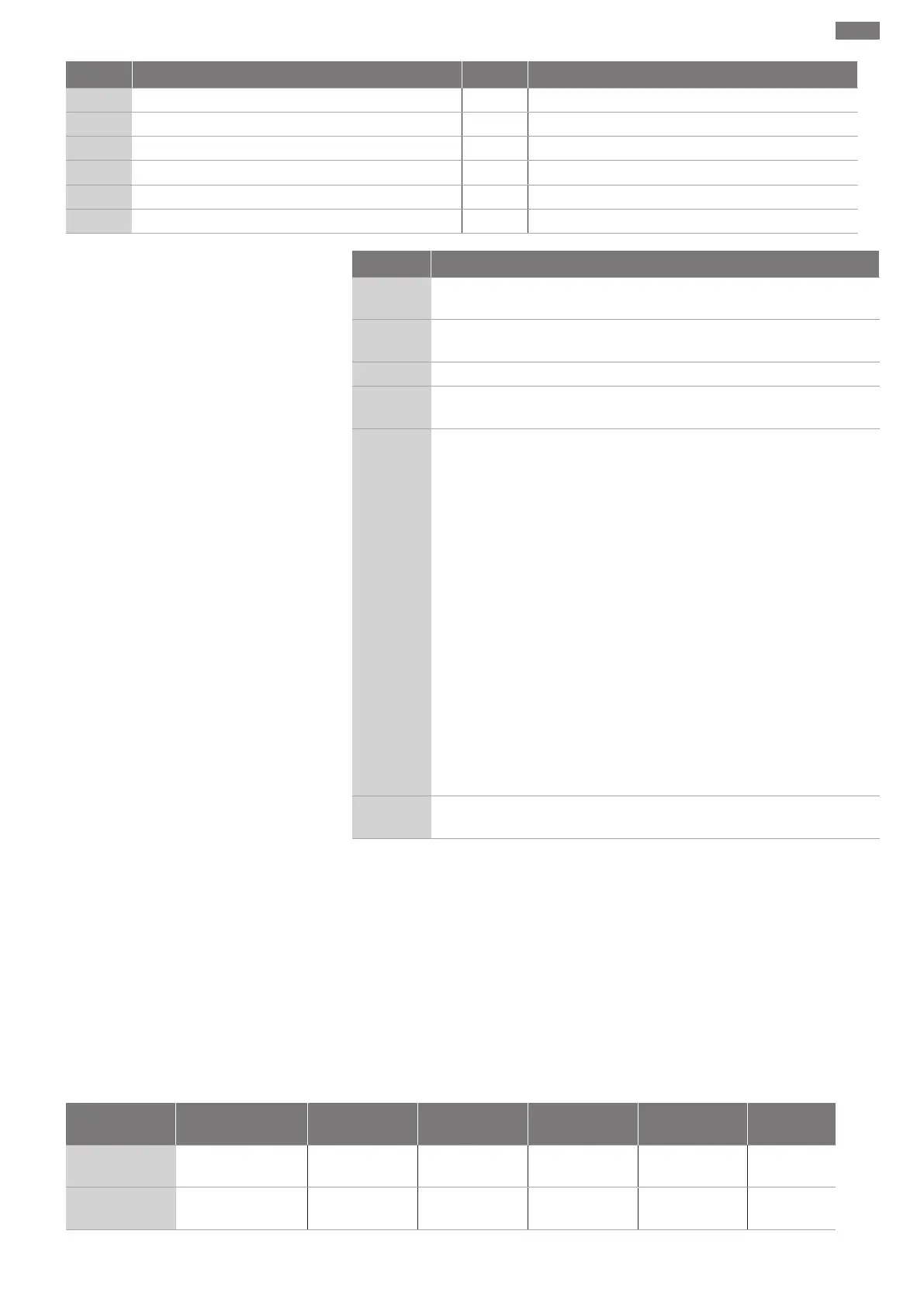

Terminal Function Terminal Function

20/21/22 Output: Collective fault signal 67/68 Input: Leakage detection pump 3

23/24 Input: Pump 1 thermal winding monitor 75/76 Input: “Dry-running protection” float switch (ex-mode)

25/26 Input: Pump 2 thermal winding monitor 77/78 Input: Thermal winding monitor pump 1 (ex-mode)

27/28 Input: Pump 3 thermal winding monitor 79/80 Input: Thermal winding monitor pump 2 (ex-mode)

29/30 Input: Extern OFF 81/82 Input: Thermal winding monitor pump 3 (ex-mode)

31/32 Input: “Dry-running protection” float switch

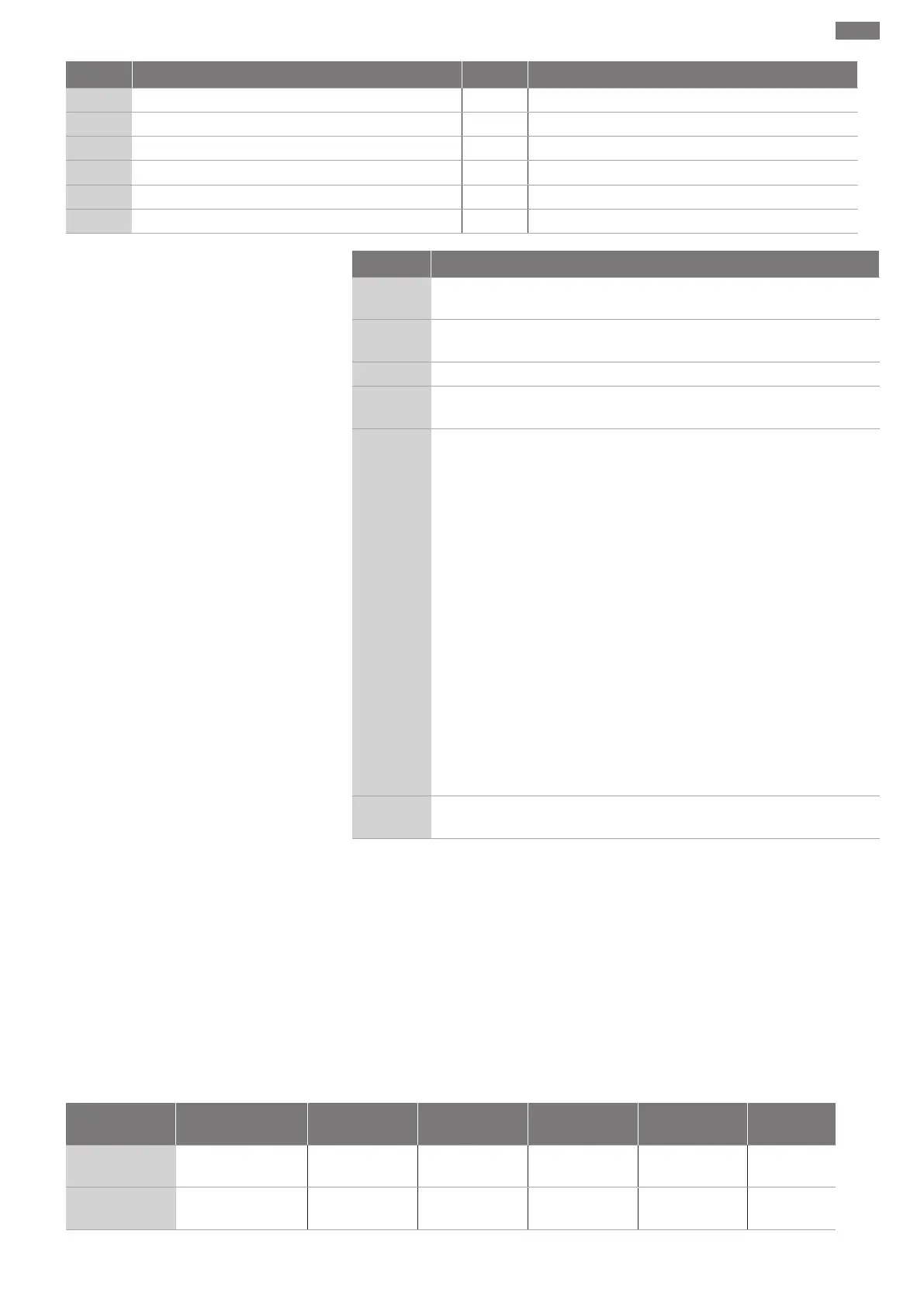

13.5 ModBus: Data types

Data type Description

INT16 Integer in the range from -32768 to 32767.

The number range actually used for a data point may vary.

UINT16 Unsigned integers in the range from 0 to 65535.

The number range actually used for a data point may vary.

ENUM Is a list. Only one of the values listed in the parameters can be set.

BOOL A Boolean value is a parameter with exactly two states (0–false and 1–

true). Generally, all values greater than zero are classified as true.

BITMAP* Is an array of 16Boolean values (bits). Values are indexed from 0 to 15. The

number read from or written to the register is the sum of all bits with the

value 1 multiplied by 2 to the power of its index.

• Bit 0: 2

0

=1

• Bit 1: 2

1

=2

• Bit 2: 2

2

=4

• Bit 3: 2

3

=8

• Bit 4: 2

4

=16

• Bit 5: 2

5

=32

• Bit 6: 2

6

=64

• Bit 7: 2

7

=128

• Bit 8: 2

8

=256

• Bit 9: 2

9

=512

• Bit 10: 2

10

=1024

• Bit 11: 2

11

=2048

• Bit 12: 2

12

=4096

• Bit 13: 2

13

=8192

• Bit 14: 2

14

=16384

• Bit 15: 2

15

=32768

BITMAP32 Is an array of 32Boolean values (bits). Please check Bitmap for the calcula-

tion details.

* Example for clarification:

Bit 3, 6, 8, and 15 are 1. All others are 0. The sum is then 2

3

+2

6

+2

8

+2

15

=8+64+256+32768

=33096. It is also possible to do the calculation the other way round. Based on the bit with

the highest index, check whether the read number is greater than/equal to the power of

two. If this is the case, bit 1 is set and the power of two is deducted from the number. Then

the check with the bit with the next lower index and the recently calculated residual num-

ber is repeated until bit 0 is obtained or the residual number is zero. Example for clarifica-

tion: The read number is 1416. Bit 15 will be 0, since 1416<32768. Bits 14 to 11 will also

be 0. Bit 10 will be 1, since 1416>1024. The remainder will be 1416-1024=392. Bit 9 will

be 0, since 392<512. Bit 8 will be 1, since 392>256. The remainder will be 392-256=136.

Bit 7 will be 1, since 136>128. The remainder will be 136-128=8. Bits 6 to 4 will be 0. Bit 3

will be 1, since 8=8. The remainder will be 0. The remaining bits 2 to 0 will thus all be 0.

13.6 ModBus: Parameter overview

Holding register

(Protocol)

Name Data type Scale & unit Elements Access* Added

40001

(0)

Version communica-

tion profile

UINT16 0.001 R 31,000

40002

(1)

Wink service BOOL RW 31,000

Loading...

Loading...