Do you have a question about the Worcester C1 and is the answer not in the manual?

Legal requirements for gas appliance installation by competent persons.

Adherence to relevant British Standards for installation and safety.

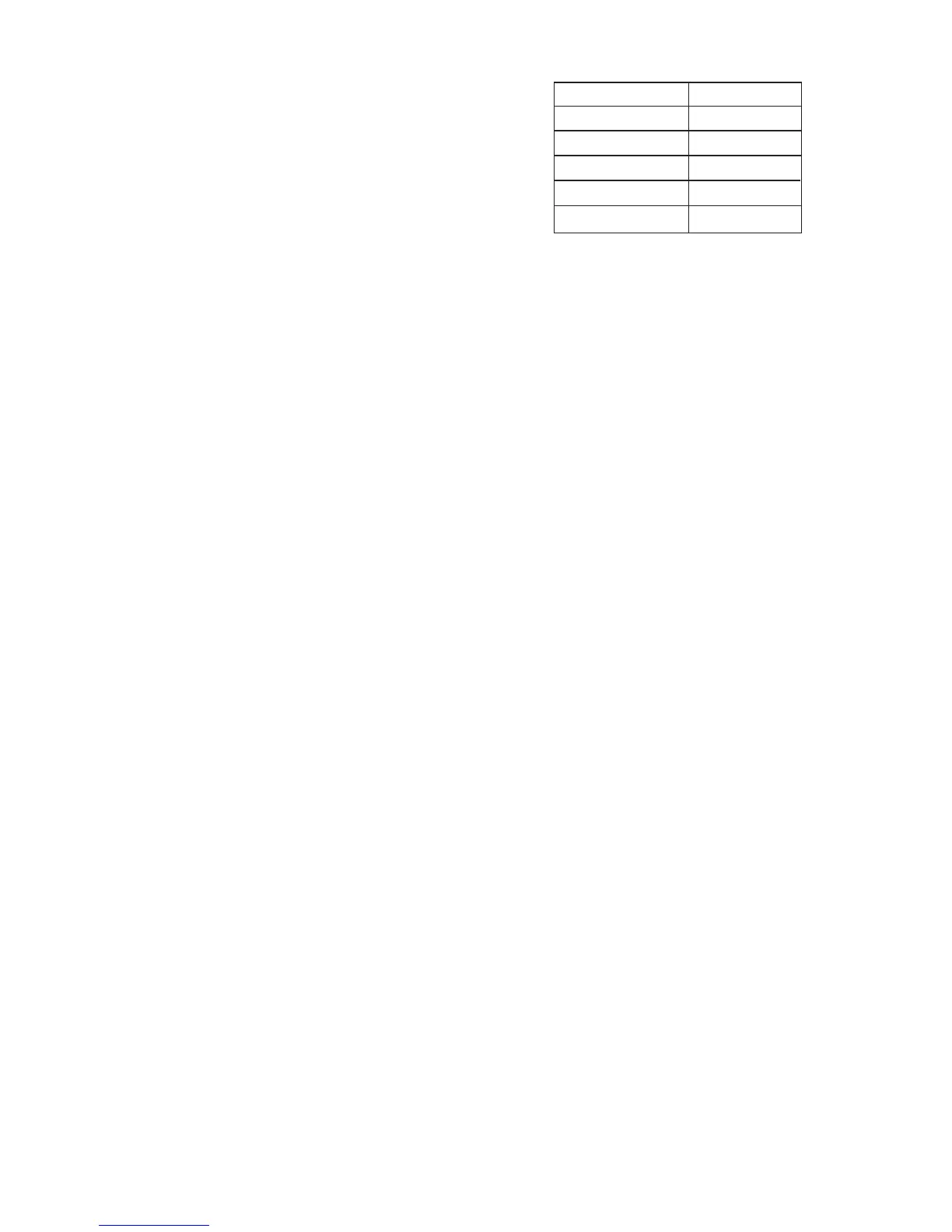

Appliance output, hot water flow, and pressure ratings.

Voltage, frequency, power consumption, and fuse ratings.

Natural gas type, flow rate, and pressure requirements.

Indoor installation, sealed systems, and compartment fitting rules.

Flue routing options and terminal requirements.

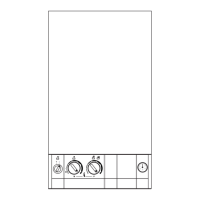

Description of controls for CH and DHW temperature adjustment.

Appliance does not need a dedicated vent for combustion air.

Minimum clearances for fitting the appliance in a cupboard.

Vents needed for compartments with reduced clearances.

Specified free areas for air vents from the room or outside.

Requirements for filling, pressurising, and venting sealed systems.

Appliance is not suitable for open vent systems.

Suitability for sealed systems and flue installation standards.

Procedures for unpacking and verifying appliance components.

Checking position, wall suitability, and required clearances.

Marking and drilling points for wall mounting and flue duct.

Fitting the wall plate and connecting the manifold assembly.

Connecting gas and water pipes to the appliance manifold.

Removing cabinet, checking supplies and connections before commissioning.

Adjusting expansion vessel charge pressure based on static head.

Filling and pressurising the system to the correct operating pressure.

Configuring fitted clock or programmer settings.

Verifying gas and electricity supplies are off before pressure testing.

Presenting the user booklet and explaining its contents.

Guiding the user on safe and efficient appliance operation.

Advising users on what to do in very cold conditions.

Explaining actions if system pressure drops.

Highlighting the benefits of regular maintenance for efficiency and lifespan.

Emphasising that work must be done by qualified personnel.

Visual checks of terminal, clearances, and joints for leaks.

Measuring CO2 and CO levels for correct combustion.

Turning off supplies and checking gas soundness after work.

Referring to service section for gaining access to components.

Steps for draining the primary and DHW circuits before component removal.

Notes on using new gaskets, O-rings, and checking electrical connections.

Essential electrical checks before starting fault diagnosis.

Interpreting indicator light patterns for fault identification.

Legal requirements for gas appliance installation.

Overview of C1 appliances for DHW and central heating.

Checking radiator heating and venting during initial operation.

Maintaining and checking system pressure in sealed systems.

Information on fitting and setting a room thermostat for central heating.

Requirements for thermostatic radiator valves and advice on preventing short cycling.

Suitability of water fittings for mains pressure and shower valve use.

Managing water flow from multiple outlets simultaneously.

Effect of mains water supply failure on appliance and heating.

Turning the appliance on and off via the main switch.

Adjusting radiator water temperature and switching to hot water only mode.

Setting the domestic hot water temperature and flow adjustments.

Information on using the optional facia-mounted programmer.

How to use the reset button for slow flashing indicator lights.

Understanding the system pressure gauge readings.

Steps for turning on the appliance and setting controls.

Procedures for short and long-term shutdown of the appliance.

How the appliance behaves during and after power interruptions.

How the overheat thermostat triggers a lockout condition.