Prepare for operation

Greenstar 2000 – 6 721 820 553 (2021/02)

8

3.2 Topping up the system pressure

Your installer should have informed you where to find the filling system

and instructed you in its use.

NOTICE

System fill method

▶ You must disconnect the external filling loop after re-pressurisation,

to comply with the Water Authority regulations.

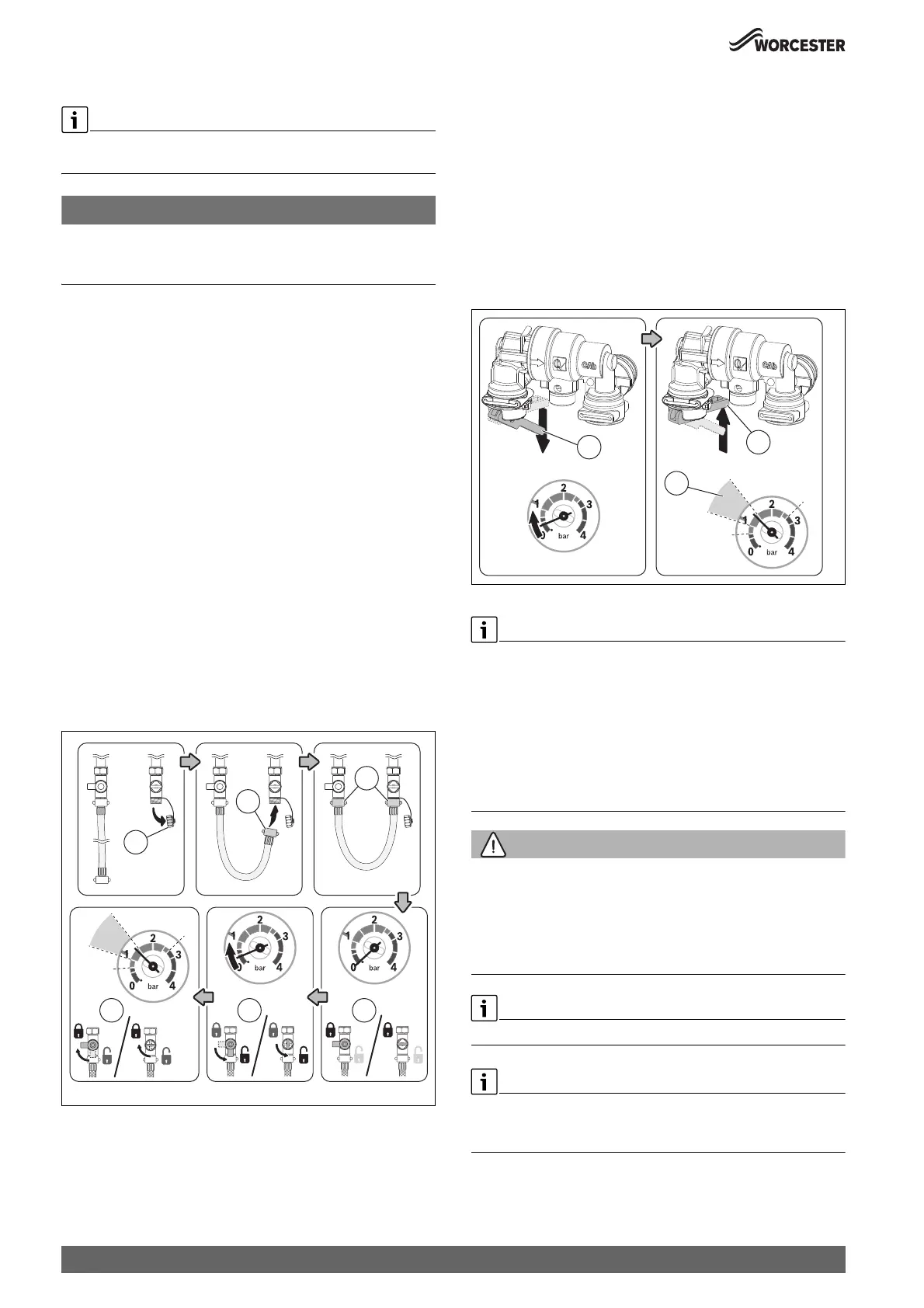

External filling loop

Once the external filling loop and pressure gauge has been located,

follow the instructions for re-pressurising the system.

Refer to figure 4.

▶ Unscrew the blanking cap [1].

▶ Attach the hose [2] to the valve.

– Usually one end of the hose is already connected to one of the

system fill isolation valves.

▶ Ensure both ends [3] of the hose are screwed on hand tight.

– The system fill isolation valves [4] are in a closed position (the

handle/screwdriver slot is across the valve).

▶ Turn the handle/screwdriver slot through 90° to open valves and

slowly fill the system to between 1 and 1.5bar.

– The system fill isolation valves [5] are opened (the handle/

screwdriver slot is in-line with the valve).

– The needle on the pressure gauge will start to rise.

▶ Turn the handles/screwdriver slots back, through 90°, to close the

valves.

– The system fill isolation valves [6] are in a closed position (the

handle/screwdriver slot is across the valve).

▶ Top up the system pressure, if as a result of the air bleeding the

pressure drops off.

▶ Remove the hose [2] and replace the blanking cap [1].

Fig. 4 External filling loop

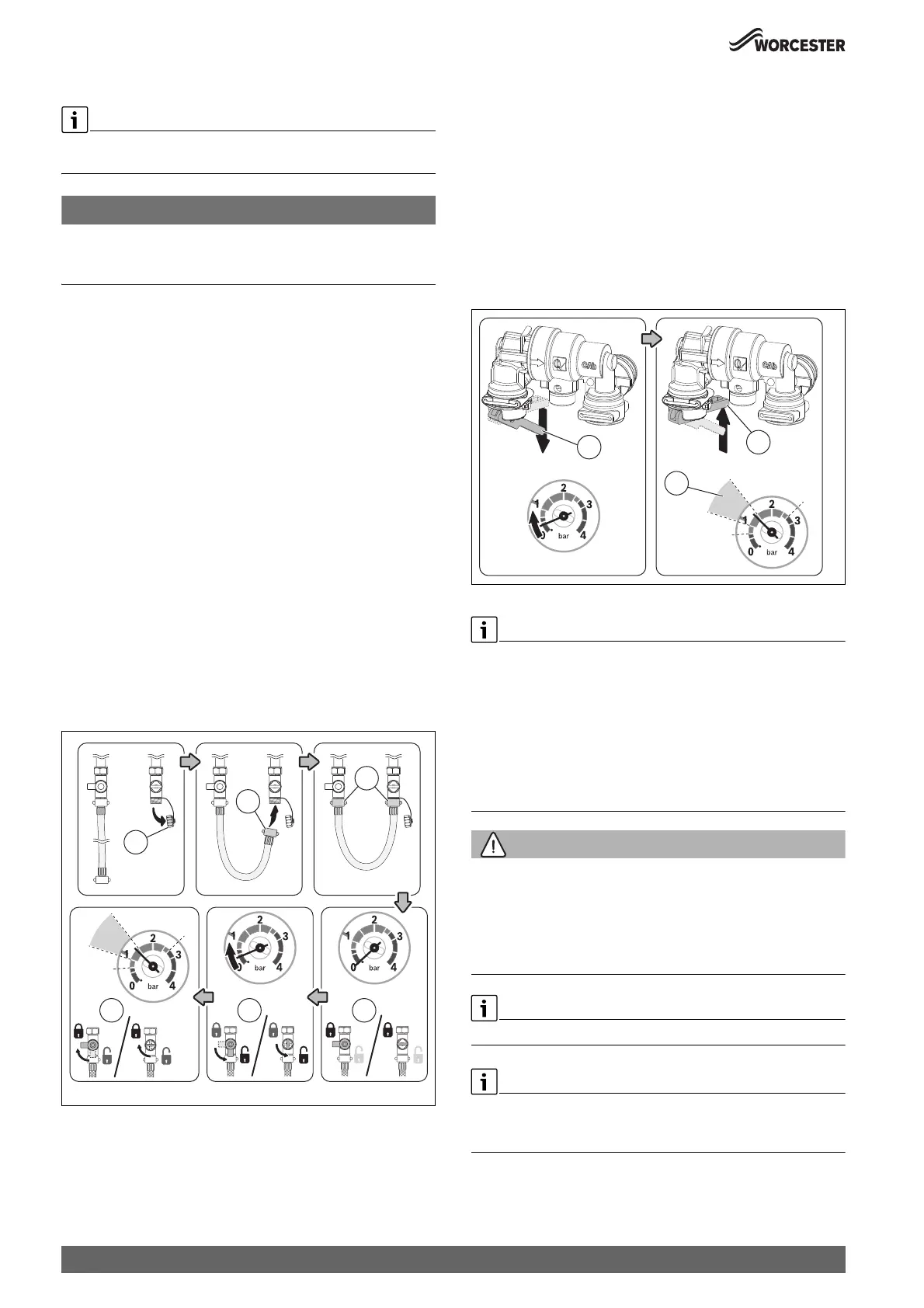

Keyless filling link

Locate the filling link (underneath the appliance on the right hand side)

and follow the instructions for re-pressurising the system.

Re-pressurise the system.

▶ To start the filling process, pull the lever [1] down.

– The needle on the pressure gauge will start to rise.

▶ To stop the filling process, release the lever [1] when:

– The pressure, shown on the pressure gauge, reaches between the

1 and 1.5 bar [2].

▶ Top up the system pressure, if as a result of the air bleeding, the

pressure drops off.

Fig. 5 Keyless filling link

If the pressure gauge reads more than 1.7 bar as a result of over filling:

▶ Bleed one radiator until the pressure gauge returns to between 1 and

1.7 bar.

▶ It is good practice to bleed any excess air that has entered the heating

system due to pressure loss. Locate and open the radiator's bleed/

vent point, closing the valve when water begins to flow.

▶ If, through normal boiler operation, the PRV pipe starts to leak, it

could be a sign of system pressure being too high. In this instance

please bleed a radiator as described above.

WARNING

Risk of damage to the system from corrosion!

If the pressure in your heating system is repeatedly rising and you are

repeatedly venting radiators, this can indicate that there is corrosion

occurring within the heating system.

To prevent serious damage to the entire system:

▶ Contact a heating engineer.

Failure to properly maintain the heating system may affect your warranty.

System pressure can be checked via the boiler’s pressure gauge/reading

when the system is cold, ensuring the reading is in the green zone at all

time.

0010015034-001

1

2

3

4

5

6

Min

1 bar

1.5 bar

Max

0010015050-001

1

1

Min

1 bar

1.5 bar

Max

2

Loading...

Loading...