6

G-800DXA / -1000DXA / -2800DXA User Manual

Control Cable Installation

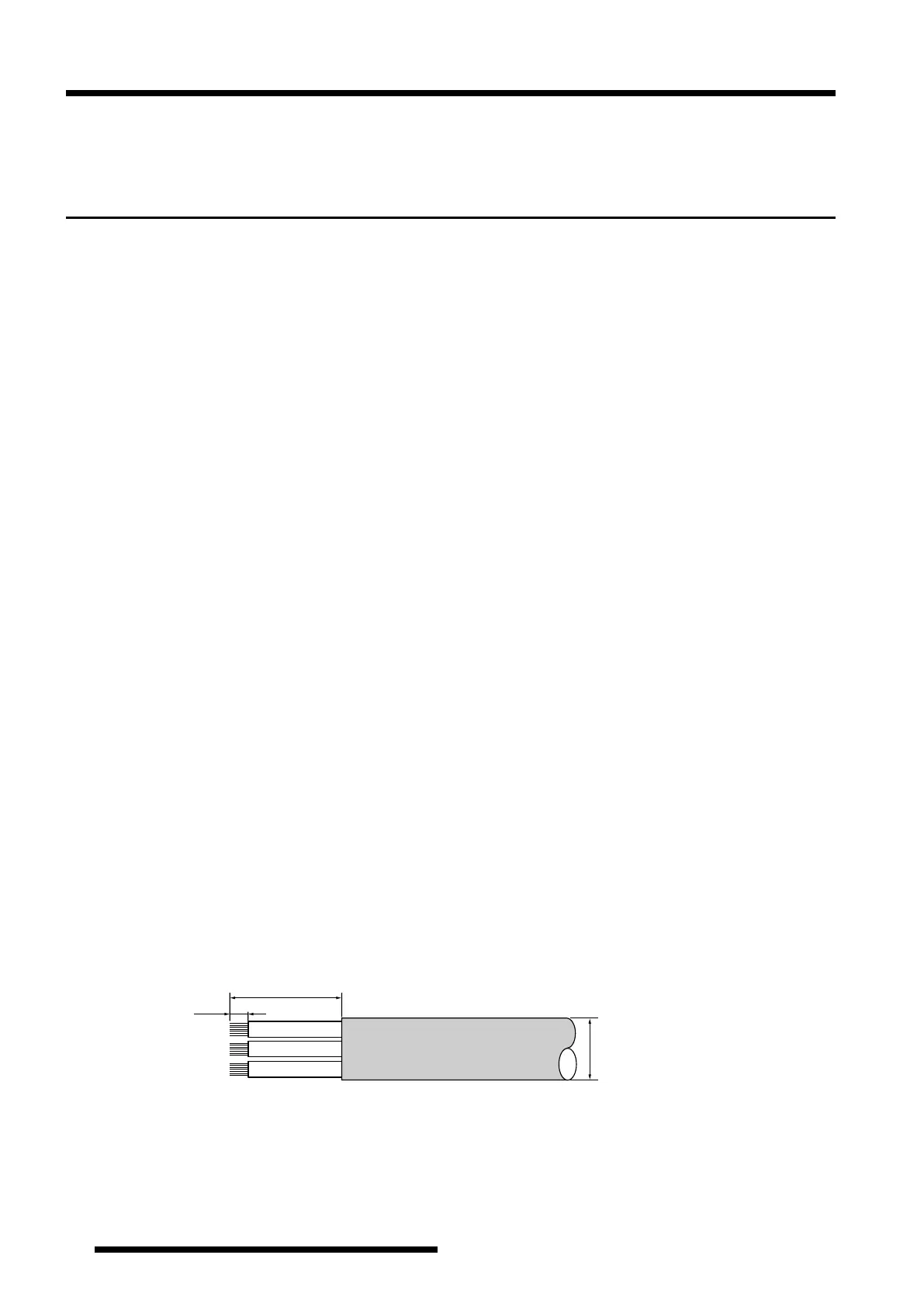

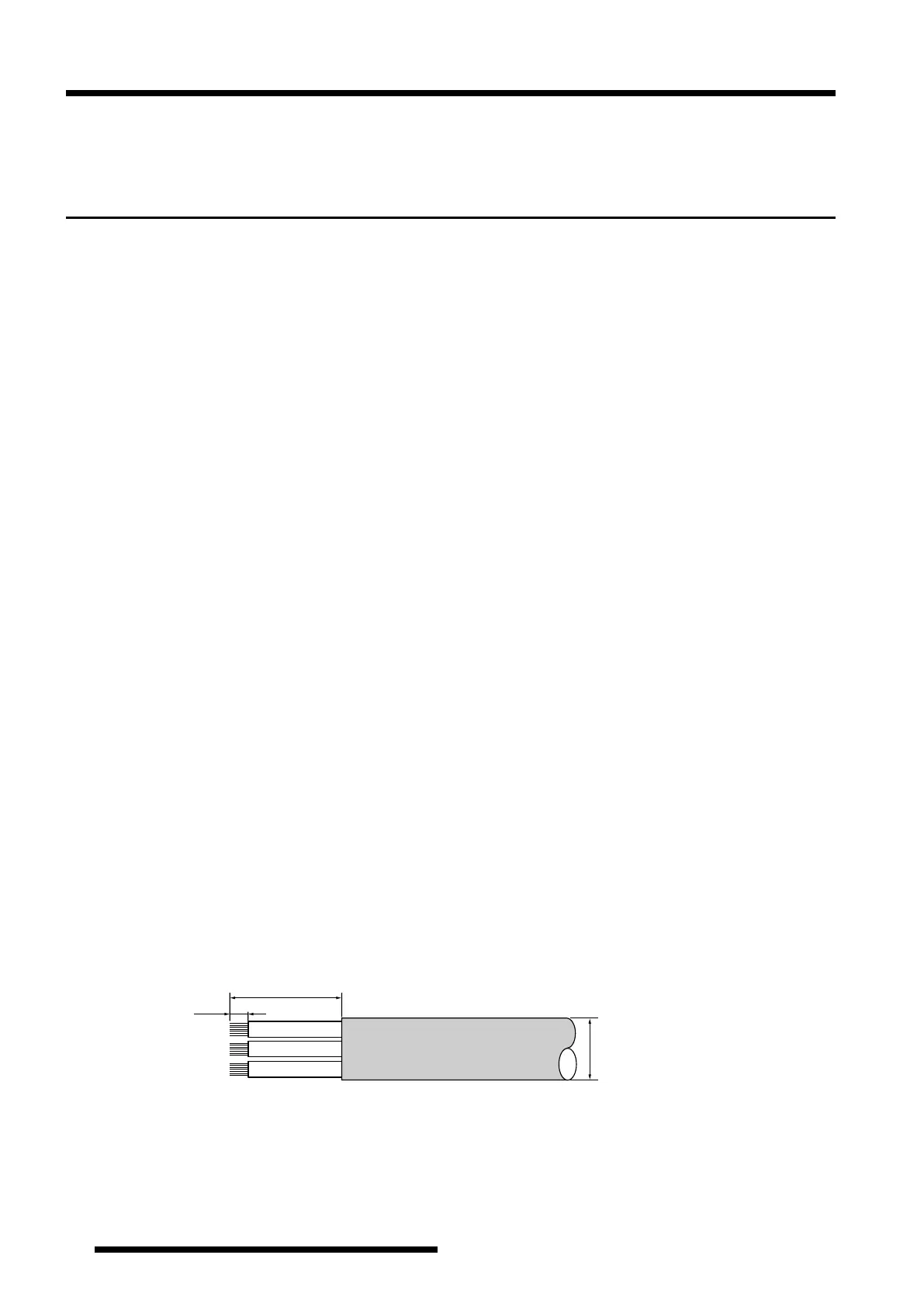

The control cable to be used should have six stranded

conductors of at least 0.5 mm (#20 AWG) diameter if the

cable is shorter than 40 m in length (125’); if the cable is

longer than 40 m, use conductors with a diameter of 0.75

mm (#18 AWG) or larger.

1. Disassemble the supplied round plug: slide off the

rubber boot, remove the setscrew from the shell using

a small screwdriver, then unscrew the shell from the

plug. Save the setscrew in a safe place until step 10,

so you don lose it.

2. Slide the rubber boot, the round shell and the connec-

tor assembly components onto the “rotator” end of the

cable as illustrated. Leave enough cable protruding to

allow easily dressing the end of the cable.

3. Using special care to avoid nicking the insulation of

the individual wires, strip back 20 mm (about 25/32”)

of the outer jacket from the both ends of the cable.

Now strip 4 mm (about 5/32”) of insulation from each

wire, being careful not to nick the conductors.

4. Solder the wires to the (rotator end) round plug pins.

Note the color of the wire and the number associated

with each pin for reference later. Pin 7 of the round

connector is not used! Conrm that all solder joints

are firm and cleanly made, as this part of the cable

will be difcult to access once the rotator is installed

on top of the tower. Do not slide the shell onto the

connector at this time.

5. Crimp the supplied pin contacts onto the wires on the

opposite (controller) end of the cable, per the illustra-

tion on the next page.

6. Referring to your notes of the wire color at each pin

of the round (rotator end) connector, insert the pins

into the supplied rectangular plug at the opposite

(controller) end of the cable. Be sure that each wire

from the round connector is routed to the correspond-

ing pin number in the rectangular connector (i.e. 1 to 1,

2 to 2, etc.).

7. Temporarily connect the round plug to the rotator,

and the rectangular plug to the controller. Make sure

that the

POWER

switch on the controller is set to

“OFF”, then plug the controller’s AC cable into your

station’s AC outlet.

8. Set the controller’s

POWER

switch to “ON”. The pi-

lot lamps on the controller should become illuminat-

ed, and the meter needle on the controller may rotate

so as to align itself with the current position of the

rotator (remember the two units have not been aligned

with each other).

9. Press the

LEFT

(rotation) side of the seesaw switch,

and conrm that the rotator (when viewed from the

top) and the controller’s needle turn counter-clock-

wise together. Stop rotation, then press the

RIGHT

(rotation) side of the seesaw switch, and conrm that

the rotator and indicator needle turn clockwise. If ro-

tation does not occur as indicated, turn the

POWER

switch “OFF”,

and re-check your cable connections.

10. If the rotator and controller are working as described,

replace the plug shells, setscrew, and rubber boot (re-

moved in step 1).

Before installing the rotator, mast, and antenna, prepare the rotator control cable and test rotator system performance on the

ground. Potential alignment, cabling, or other problems can quickly be resolved on the ground; once a rotator is mounted,

however, troubleshooting may require that the tower be climbed and/or the rotator be removed and lowered to the ground!

Control Cable Preparation (G-800DXA/-1000DXA)

In the

G-800DXA

and

G-1000DXA

models, the user must supply and prepare the control cable, per the simple instructions

below.

8.6〜10.5mm

4mm

Loading...

Loading...