5353649-UIM-A-0617

5

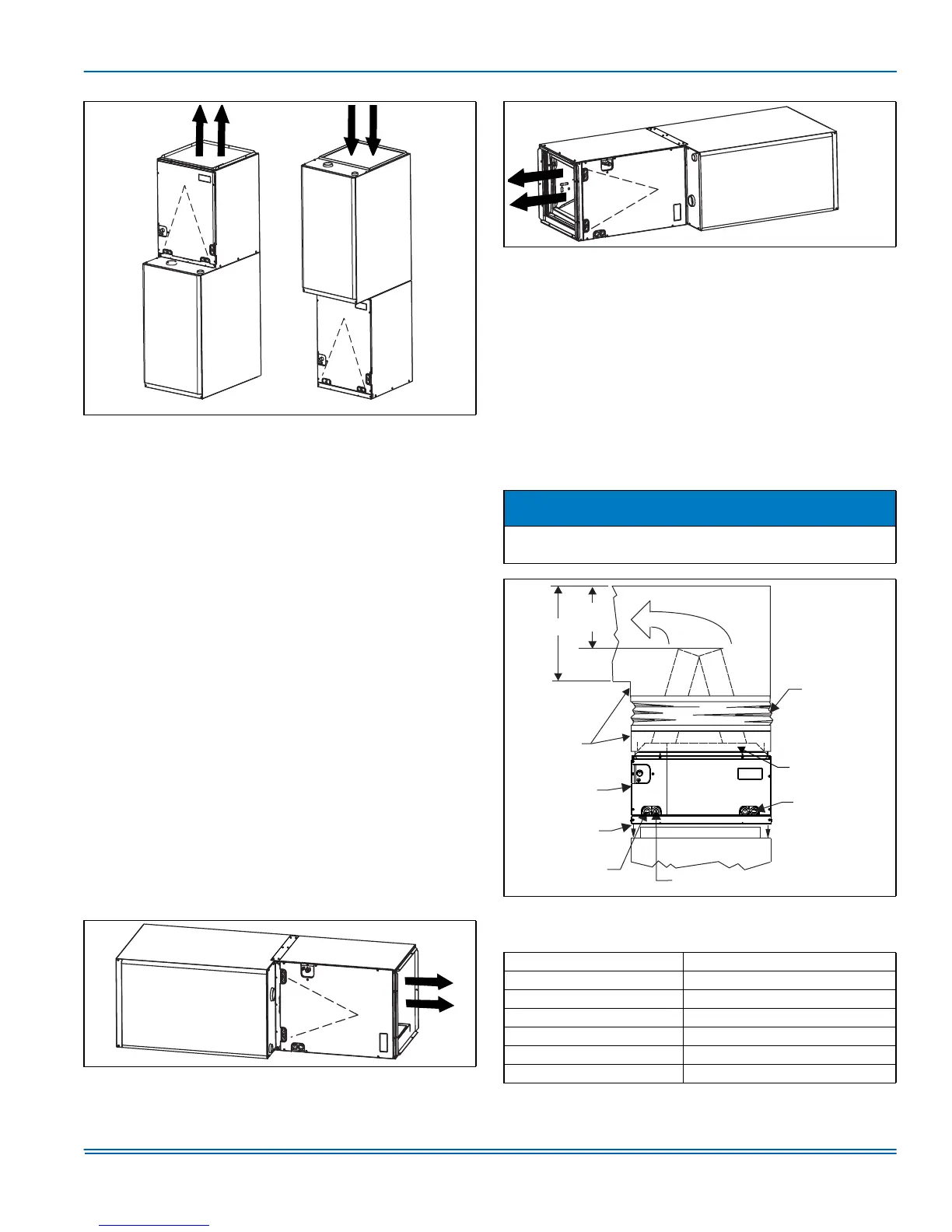

For upflow or downflow applications (FC/MC Models):

These coils are factory shipped for installation in either upflow or down-

flow applications with a minor conversion.

1. Remove and reposition the coil duct flanges as shown in figure 5 if

needed.

2. Position the coil on the furnace opening (or the furnace on the coil

for downflow) as shown in Figure 6.

3. Place the ductwork over the coil (or furnace) duct flanges and

secure.

4. Check for air leakage between the furnace and coil casing and seal

appropriately. Three tie plates are provided with the coils. If

needed, secure the coil to the furnace using these tie plates.

5. See sections on “Refrigerant Line Connections” and “Condensate

Drain Connections” for further installation instruction.

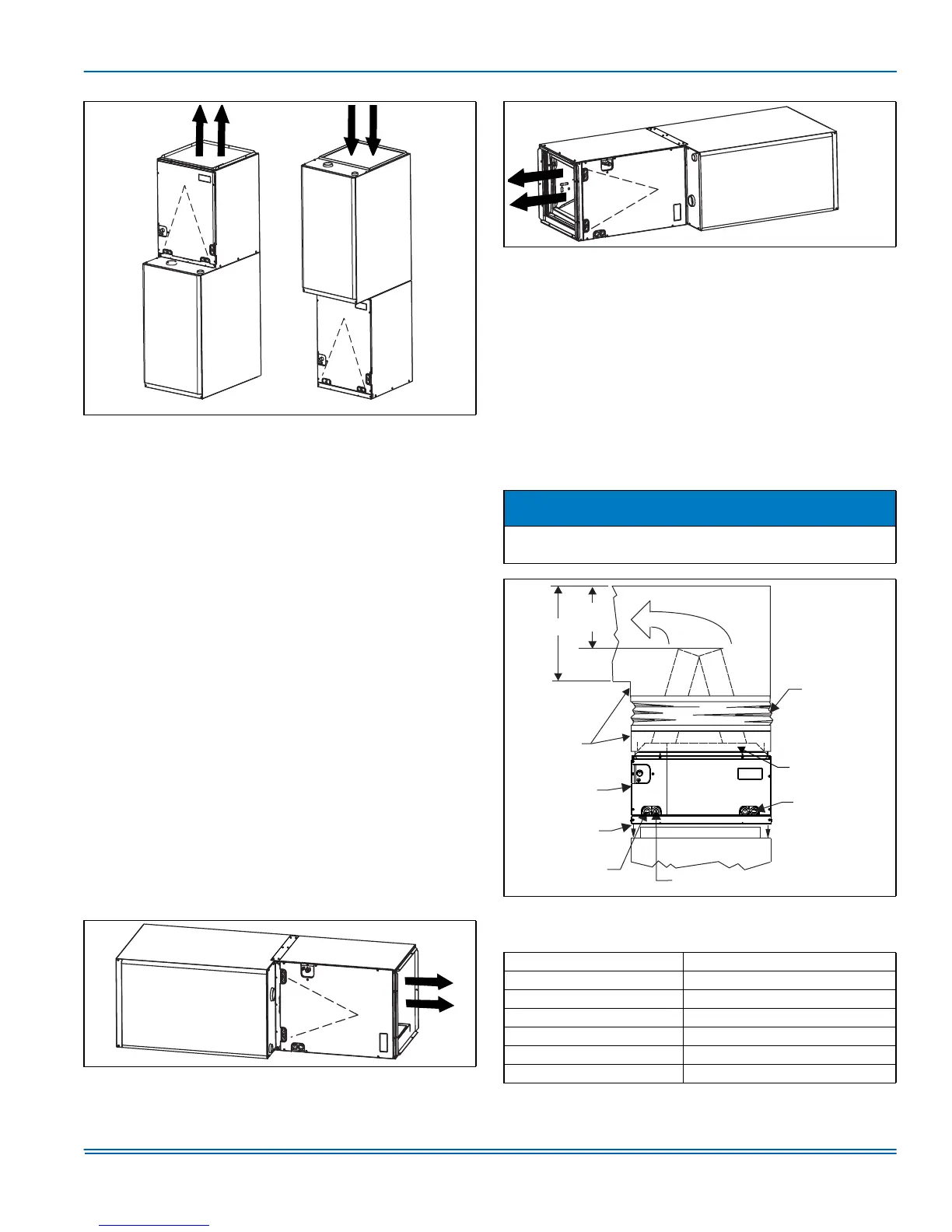

For horizontal applications (MC models only):

MC model coils are supplied ready to be installed in a horizontal posi-

tion. A horizontal drain pan is factory installed.

1. Remove and reposition the coil duct flanges as shown in figure 5 if

needed.

2. Position the coil and furnace as shown in Figure 7.

3. Place the ductwork over the coil or furnace duct flanges and

secure.

4. Check for air leakage between the furnace and coil casing and seal

appropriately. Three mounting plates are provided with the coils.

The mounting plates must be used to secure the top edges of the

furnace and coil together. See figures 7 and 8.

5. See sections on “Refrigerant Line Connections” and “Condensate

Drain Connections” for further installation instruction.

FURNACE ASSEMBLY - PC

The PC coils are designed for installation on top of upflow furnaces

only.

If the coil is used with a furnace of a different size, use a 45° transition

to allow proper air distribution through the coil.

1. Remove and reposition the coil duct flanges as shown in figure 5 if

needed.

2. Position the coil casing over the furnace opening as shown in Fig-

ure 9.

3. Place the ductwork over the coil duct flange and secure.

4. Check for air leakage between the furnace and coil casing and seal

appropriately.

Dimension “C” should be at least 2/3 of dimension “D”. See Figure 9.

FIGURE 6: Vertical Applications with Furnaces

FIGURE 7: Horizontal Right Application with Furnaces

UPFLOW

DOWNFLOW

Furnace

Furnace

Furnace

FIGURE 8: Horizontal Left Application with Furnaces

NOTICE

Refer to the heat pump add-on control instruction before installing an

add-on heat pump coil.

FIGURE 9: Upflow - PC Coil Installation with Furnace

TABLE 5:

Coil Projection Dimensions - PC Coils

COIL SIZE DIMENSION “C” INCH

PC18 3-1/2

PC24 4-1/2

PC30, PC32, PC35 4-1/2

PC42, PC43, PC36, PC37 5-1/2

PC48 6-1/2

PC60 9

Furnace

Flexible Duct

Collar

DO NOT Drill or

Screw this Flange

Field

Fabricated

Ductwork

Upflow Coil

Upflow Furnace

Secondary Drain

Primary Drain

D

C

(Min.)

Alternate

Drain Location

Loading...

Loading...