5353649-UIM-A-0617

6

CRITICAL COIL PROJECTION

The coil assembly must be located in the duct such that a minimum dis-

tance is maintained between the top of the coil and the top of the duct.

Refer to Table 5.

SECTION V: DUCT CONNECTIONS

Air supply and return may be handled in one of several ways best

suited to the installation. Upflow, horizontal or downflow applications

may be used.

The vast majority of problems encountered with combination heating

and cooling systems can be linked to improperly designed or installed

duct systems. It is therefore highly important to the success of an instal-

lation that the duct system be properly designed and installed.

Use flexible duct collars to minimize the transmission of vibration/noise

into the conditioned space.

Where return air duct is short, or where sound may to be a problem,

sound absorbing glass fiber should be used inside the duct. Insulation

of duct work is a must where it runs through an unheated space during

the heating season or through an uncooled space during the cooling

season. The use of a vapor barrier is recommended to prevent absorp-

tion of moisture from the surrounding air into the insulation. The supply

air duct should be properly sized by use of a transition to match unit

opening. All ducts should be suspended using flexible hangers and

never fastened directly to the structure. Duct work should be fabricated

and installed in accordance with local and/or national codes. This

includes the standards of the National Fire Protection Association for

Installation of Air-Conditioning and Ventilating Systems, NFPA No. 90B.

SECTION VI: CONDENSATE DRAIN

CONNECTIONS

All drain lines should be pitched away from unit drain pan and should be

no smaller than the coil drain connection.

Route the drain line so that it doesn’t interfere with accessibility to the

coil, furnace, air handling system or filter and will not be exposed to

freezing temperatures.

Instruct the owner that the evaporator coil drain pan should be

inspected and cleaned regularly to prevent odors and assure proper

drainage.

Coils should be installed level or pitched slightly toward the drain end.

Suggested pitch should not exceed 1/4-inch per foot of coil.

If the coil is provided with a secondary drain it should be piped to a loca-

tion that will give the occupant a visual warning that the primary drain is

clogged. If the secondary drain is not used it must be capped.

DO NOT use Teflon

TM

tape, “pipe dope”, or other sealants. The use of

a sealant may cause damage and premature failure of the drain pan.

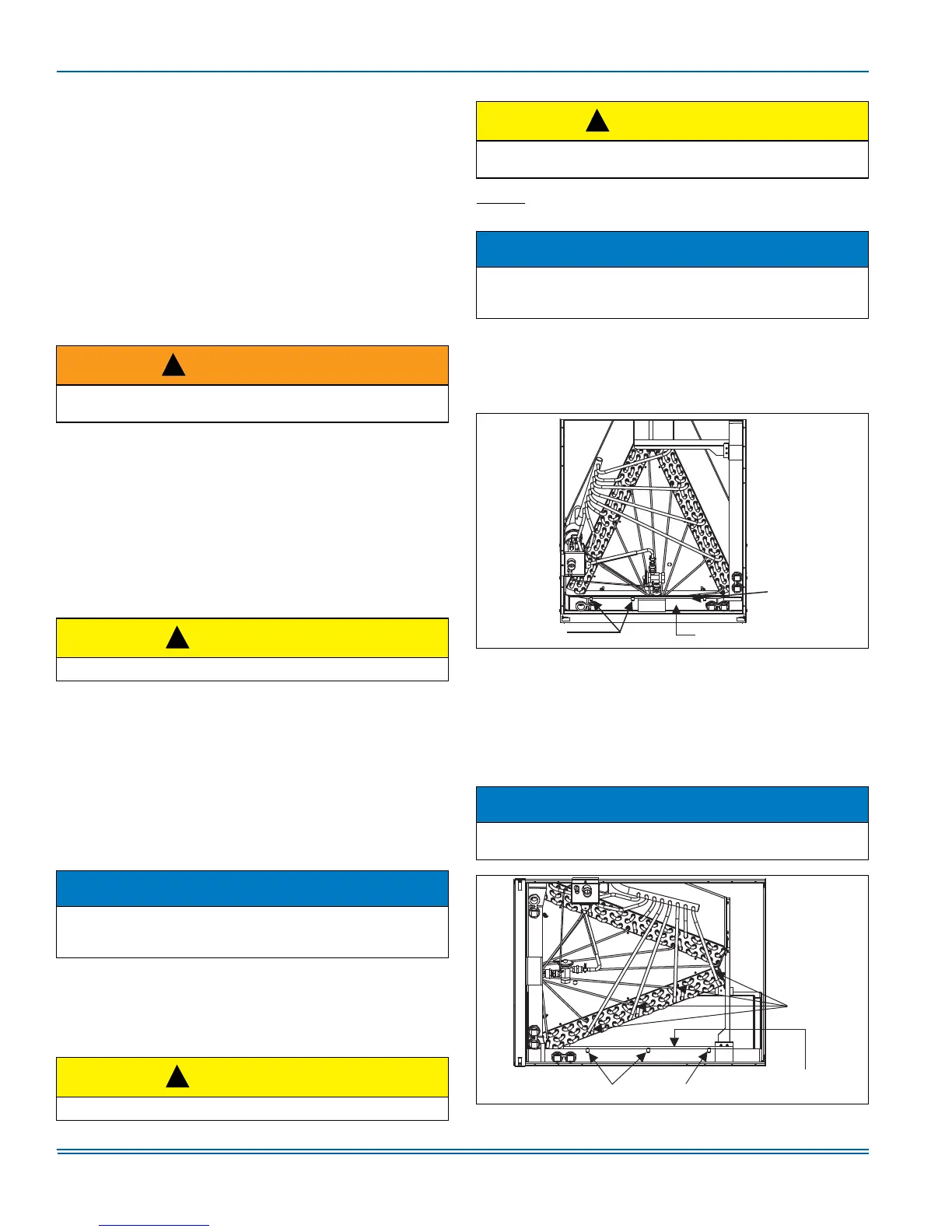

SUCTION FEEDER TUBE CONDENSATE

DEFLECTOR

Upflow or Downflow

No action required. See Figure 10.

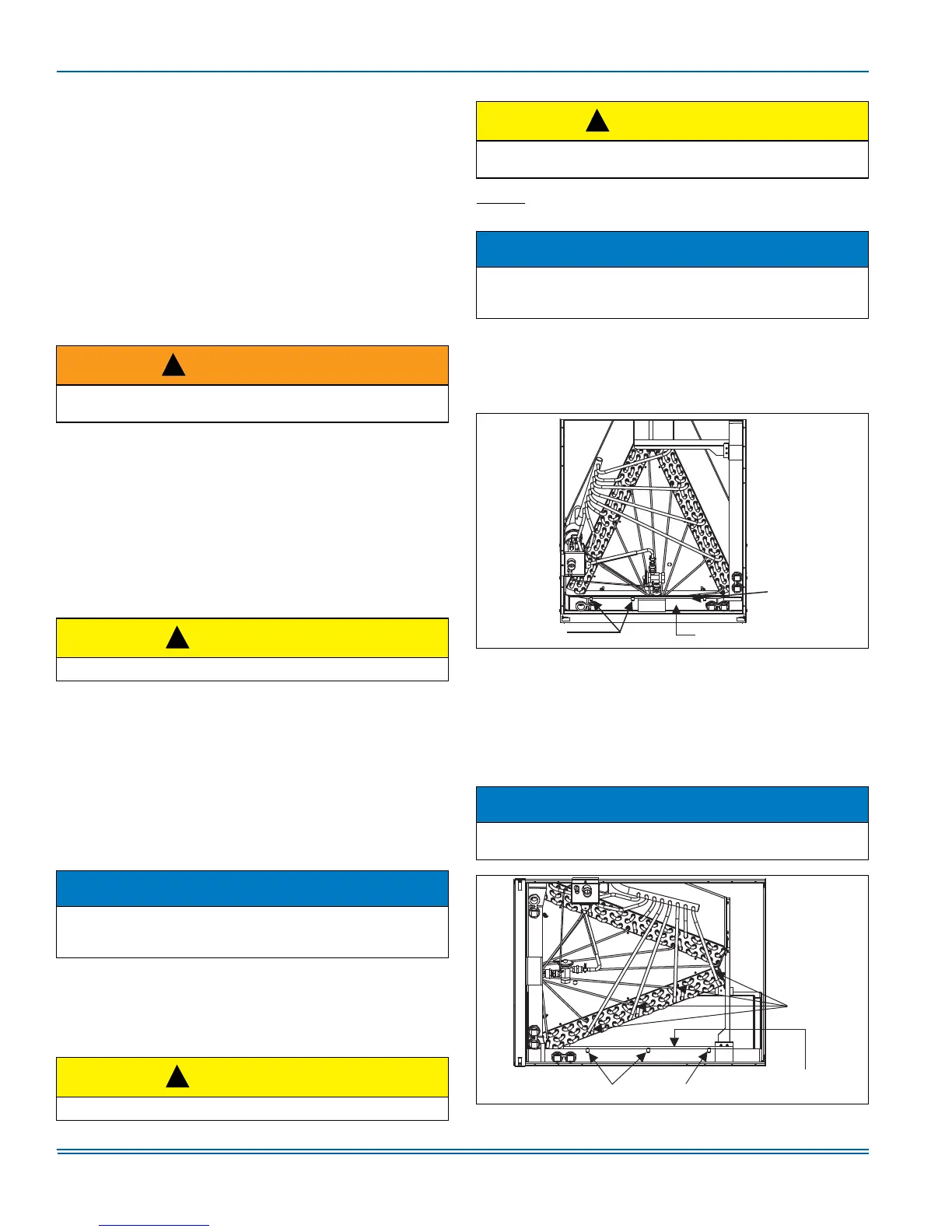

Horizontal Left or Right

Use an appropriate tool to pry out water deflector with two or three s-

clips from the vertical drain pan. See Figure 11. Relocate the deflector

with s-clips on the Horizontal Drain Pan lined up to the coil support

bracket. See Figure 12. This positions the deflector below the feeder

tubes to channel the condensate to the drain pan.

WARNING

Use 1/2" screws to connect ductwork to unit. If pilot holes are drilled,

drill only through field duct and unit flange.

CAUTION

Equipment should never be operated without filters.

NOTICE

When the coil is installed in an attic or above a finished ceiling, an

auxiliary drain pan must be provided under the coil as is specified by

most local building codes.

CAUTION

Avoid Double Trapping.

!

!

!

CAUTION

Threaded drain connections should be hand tightened, plus no more

than 1 turn.

NOTICE

If the coil is installed in a draw-thru application (modular air handler),

it is recommended to trap the primary and secondary drain line. If the

secondary drain line is not used, it must be capped.

FIGURE 10: Condensate Deflector on Vertical Drain Pan

NOTICE

The condensate deflector should be installed in the s-clip section

which is inside the drain pan edge. See Figure 12.

FIGURE 11: Condensate Deflector on Horizontal Drain Pan Edge

!

Condensate

Deflector

S-Clips (3)

Vertical Drain Pan

S-Clips on Horizontal Pan

Feeder

Tubes

Condensate

Deflector

Loading...

Loading...