035-17480-000 Rev. A (800)

UnitaryProductsGroup 19

To install the vent drain, complete the following steps:

1. Place a tee of the proper diameter for the vent system

being installed (2" or 3") in the horizontal run closest to

the furnace.

2. Place a reducer bushing of proper diameter in the stem

portion of the tee. The recommended size for the

reducer is 5/8”.

3. Place a piece of 5/8” diameter or other selected size pipe

a minimum of 3" long into the reducer to serve as a

nipple.

NOTE

:Tee, reducer and nipple must be properly cemented

together using the appropriate method and materials speci-

fied in the Combustion Air Intake/Vent Connections section of

these instructions.

4. Connect a piece of flexible drain tubing such as EPDM

rubber, Vinyl or PVC to the nipple.

5. Loop the drain tubing to provide a trap.

6. Connect the discharge end of the drain tube to the con-

densate disposal system externally to the furnace.

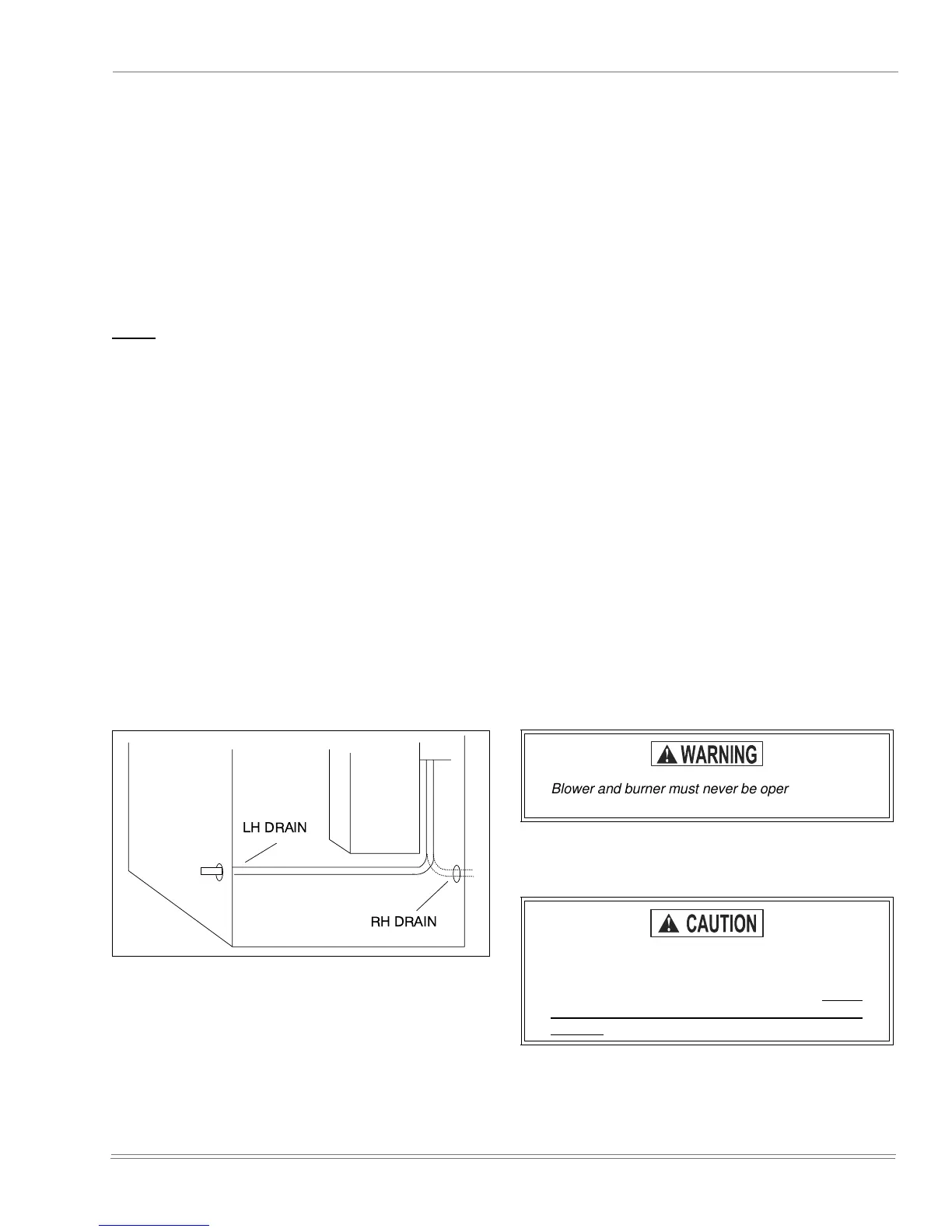

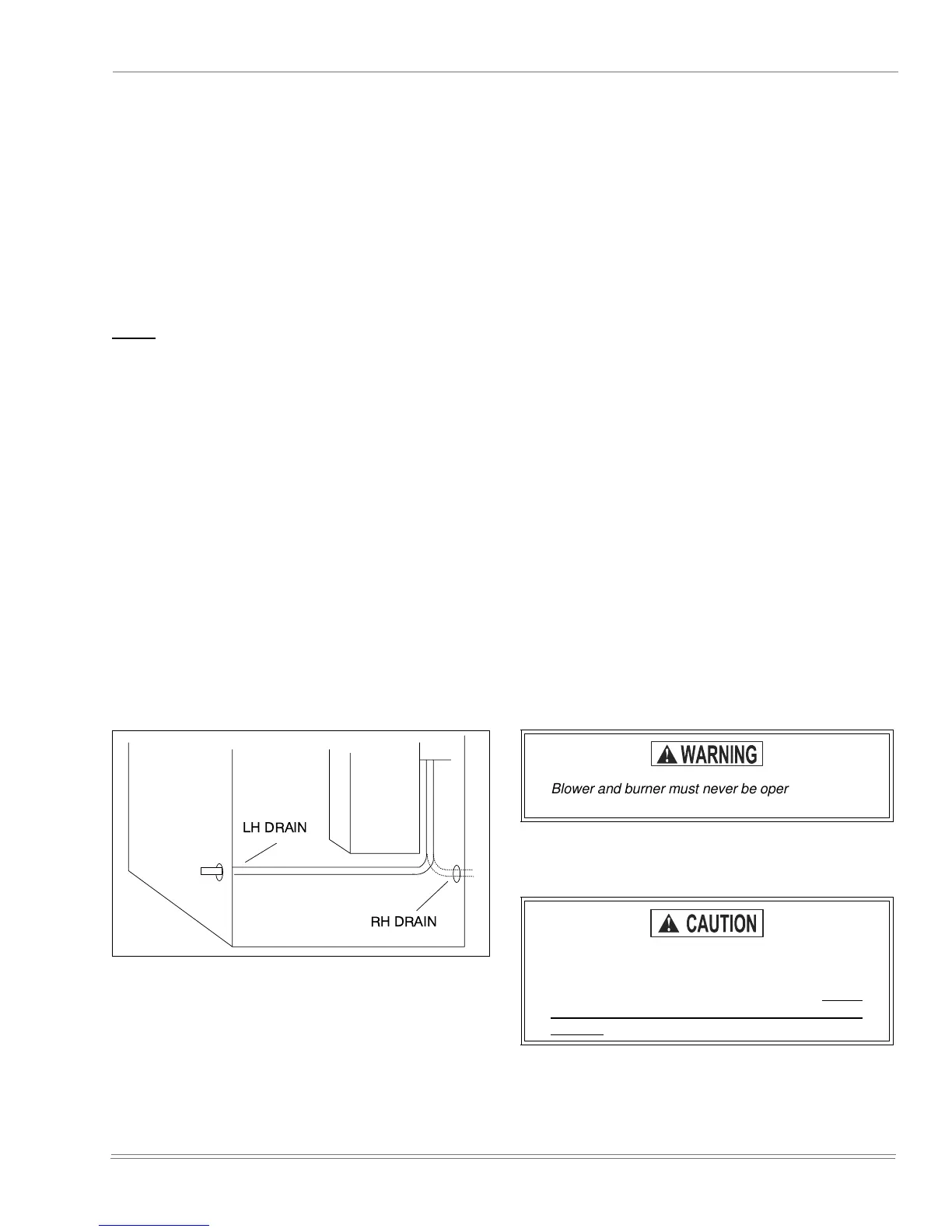

CONDENSATE PIPING

The condensate drain connection is packed in the furnace for

field installation. It consists of a formed hose with a 1/2” NPT

male connection. A 1/2” FM x 3/4” PVC slip coupling is pro-

vided.

This drain hose may be installed to allow left or right side con-

densate drain connection, (refer to Figure 23). Cut the hose

to allow for proper fit for left or right exit.

To install the drain hose assembly, remove the 7/8” knockout

in the side panel. Remove the conduit nut from the 1/2” male

fitting. Push the male fitting through the hole and reinstall the

nut. The use of the 3/4” PVC coupling is optional.

Drain Connection: The following steps apply to all models.

1. It is recommended that either 1/2” or 3/4” PVC or equiva-

lent pipe be field installed as drain pipe. The condensate

piping may be tied together with the air conditioning con-

densate drain if the air conditioning condensate drain

line is trapped upstream of the tie-in and the combined

drains are constructed of the same material.

2. All pipe joints must be cleaned, de-burred and cemented

using PVC primer and cement.

3. The furnace contains an internal trap. Therefore, no

external trap should be used.

4. If a condensate pump is used, it must be suitable for use

with acidic water.

5. Where required, a field-supplied neutralizer can be

installed in the drain line, external to the furnace.

NOTE: The condensate drain from the furnace may be con-

nected in common with the drain from an air conditioning coil

if allowed by local code. Follow the instructions with the coil

for trapping the drain.

SAFETY CONTROLS

Control Circuit Fuse: A 3 amp. fuse is provided to protect

the 24 volt transformer from overload caused by control cir-

cuit wiring errors. This is an ATO 3, automotive type fuse and

is located in the unit wiring harness between the control

transformer and the furnace control.

Blower Door Safety Switch: This unit is equipped with an

electrical interlock switch mounted in the blower compart-

ment. This switch interrupts all power at the unit when the

panel covering the blower compartment is removed.

Electrical supply to this unit is dependent upon the panel that

covers the blower compartment being in place and properly

positioned.

FIGURE 23 : Upflow Models P*XU / G9D-UP

LHDRAIN

RH

DRAIN

Blower and burner must never be operated without

the blower panel in place.

Main power to the unit must still be interrupted at

the main power disconnect switch before any ser-

vice or repair work is to be done to the unit. Do not

rely upon the interlock switch as a main power dis-

connect.

Loading...

Loading...