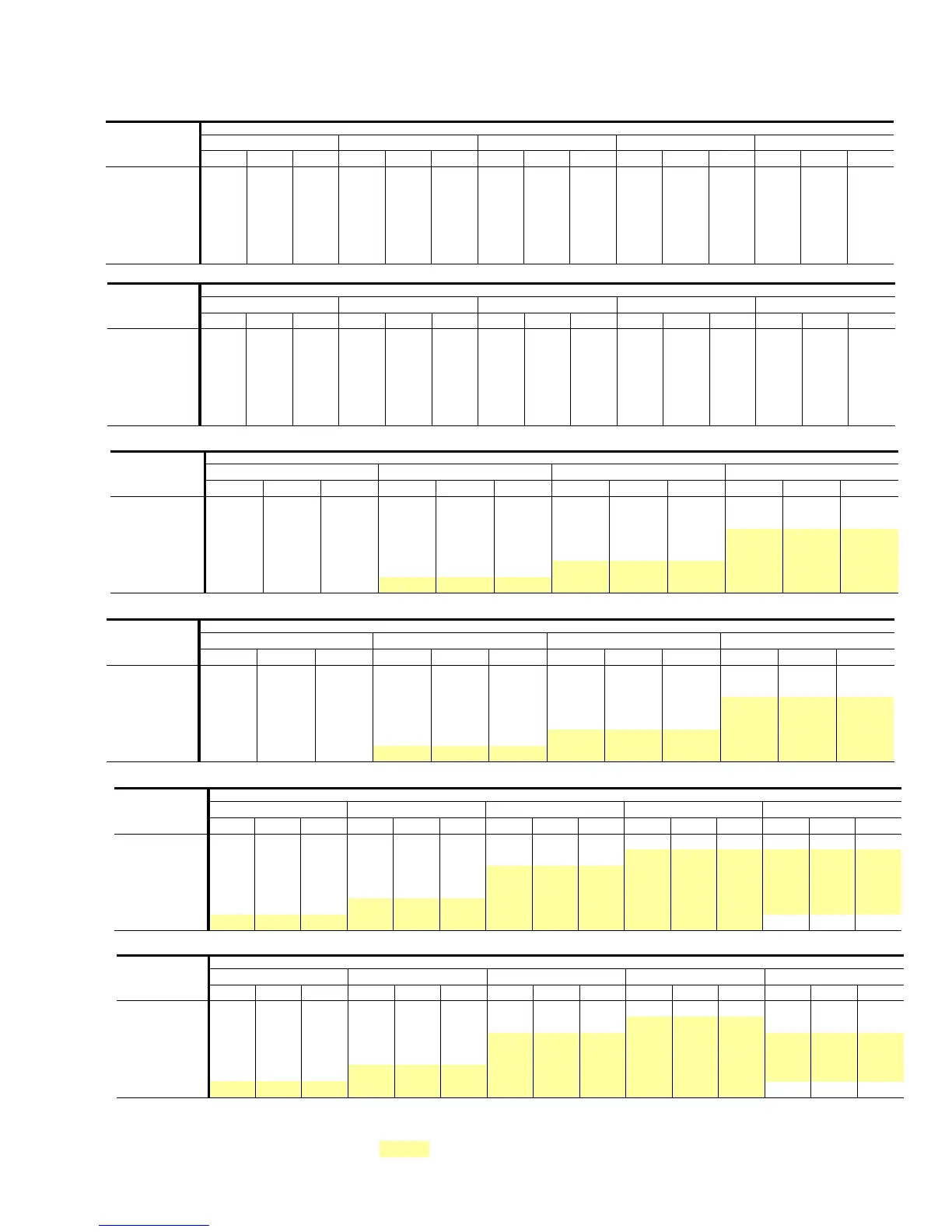

TABLE 6

- SUPPLY AIR BLOWER PERFORMANCE

(7-1/2, 8-1/2 & 10 TON)

BLOWER

SPEED,

RPM

CFM

2250 2550 3000 3400 3750

ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW

975 0.83 1.16 1.08 0.66 1.27 1.18 0.37 1.45 1.35 0.08 1.65 1.54 - - -

1025 0.98 1.21 1.13 0.82 1.34 1.25 0.52 1.54 1.44 0.21 1.75 1.63 - - -

1070 1.12 1.32 1.23 0.95 1.46 1.36 0.67 1.68 1.57 0.37 1.89 1.76 0.07 2.11 1.97

1130 1.31 1.43 1.33 1.16 1.57 1.46 0.86 1.83 1.71 0.56 2.04 1.90 - - -

1175 1.51 1.51 1.41 1.36 1.67 1.56 1.07 1.92 1.79 0.75 2.18 2.03 - - -

1220 1.68 1.66 1.55 1.53 1.81 1.69 1.23 2.10 1.96 - - - - - -

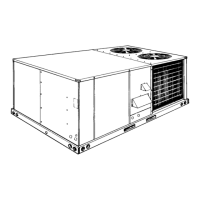

MODEL DCG090

- (SIDE DUCT APPLICATIONS)

BLOWER

SPEED,

RPM

CFM

2250 2550 3000 3400 3750

ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW

975 0.761.161.080.571.271.180.241.451.35------

1025 0.91 1.21 1.13 0.73 1.34 1.25 0.39 1.54 1.44 0.04 1.75 1.63 - - -

1070 1.05 1.32 1.23 0.86 1.46 1.36 0.54 1.68 1.57 0.20 1.89 1.76 - - -

1130 1.24 1.43 1.33 1.07 1.57 1.46 0.73 1.83 1.71 0.39 2.04 1.90 - - -

1175 1.44 1.51 1.41 1.27 1.67 1.56 0.94 1.92 1.79 0.58 2.18 2.03 - - -

1220 1.61 1.66 1.55 1.44 1.81 1.69 1.10 2.10 1.96 ------

MODEL DCG090

- (BOTTOM DUCT APPLICATIONS)

BLOWER

SPEED,

RPM

CFM

2550 3000 3400 3750

ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW

975 0.66 1.27 1.18 0.37 1.45 1.35 0.08 1.65 1.54 - - -

1025 0.82 1.34 1.25 0.52 1.54 1.44 0.21 1.75 1.63 - - -

1070 0.95 1.46 1.36 0.67 1.68 1.57 0.37 1.89 1.76 0.07 2.11 1.97

1130 1.16 1.57 1.46 0.86 1.83 1.71 0.56 2.04 1.90 0.16 2.22 2.06

1175 1.36 1.67 1.56 1.07 1.92 1.79 0.75 2.18 2.03 0.31 2.34 2.16

1220 1.53 1.81 1.69 1.23 2.10 1.96 0.86 2.37 2.15 0.48 2.78 2.56

MODEL DCG102

- (SIDE DUCT APPLICATIONS)

BLOWER

SPEED,

RPM

CFM

2550 3000 3400 3750

ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW

9750.571.271.180.241.451.35------

1025 0.73 1.34 1.25 0.39 1.54 1.44 0.04 1.75 1.63 - - -

1070 0.86 1.46 1.36 0.54 1.68 1.57 0.20 1.89 1.76 0.04 2.11 1.97

1130 1.07 1.57 1.46 0.73 1.83 1.71 0.39 2.04 1.90 0.13 2.22 2.06

1175 1.27 1.67 1.56 0.94 1.92 1.79 0.58 2.18 2.03 0.28 2.34 2.16

1220 1.44 1.81 1.69 1.10 2.10 1.96 0.66 2.37 2.15 0.36 2.78 2.56

MODEL DCG102

- (BOTTOM DUCT APPLICATIONS)

BLOWER

SPEED,

RPM

CFM

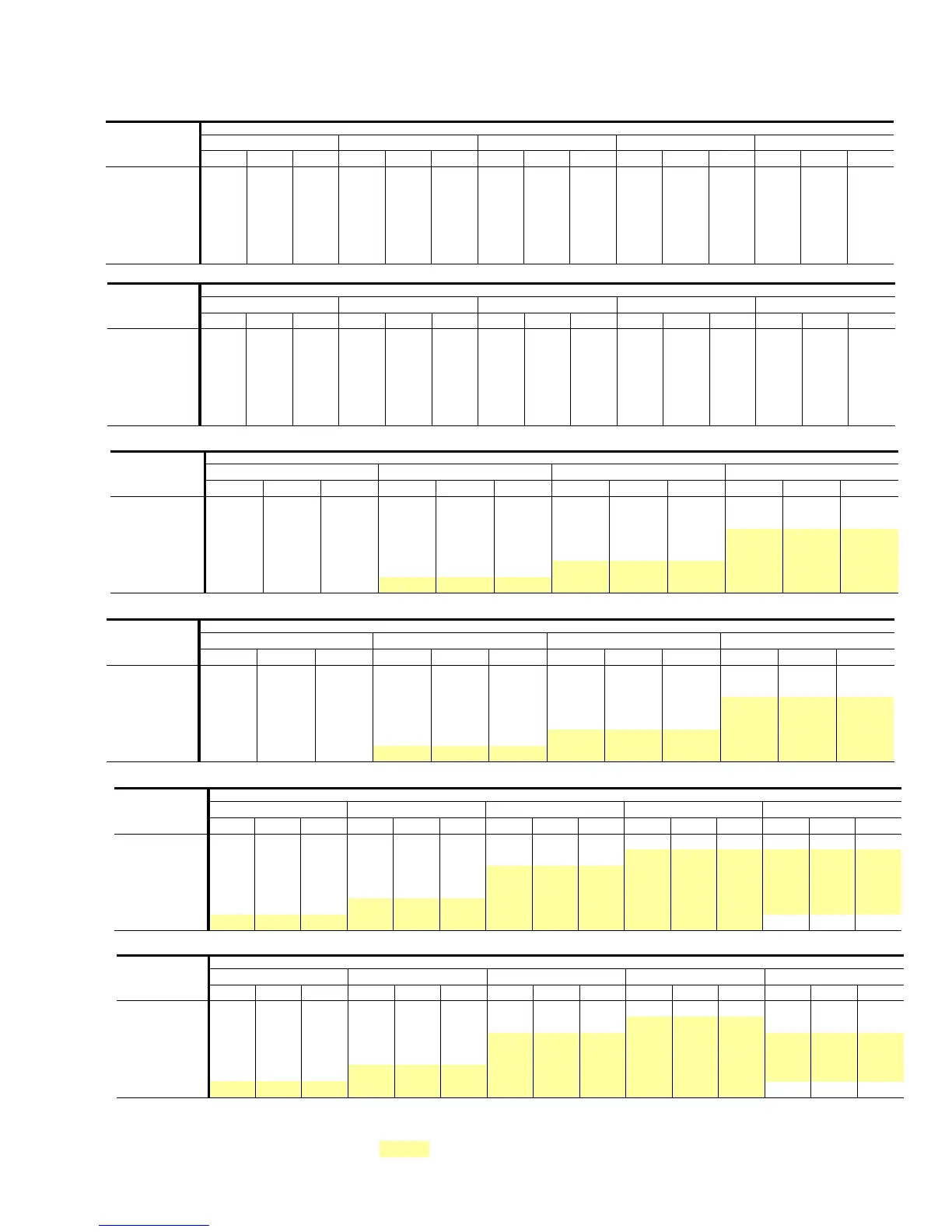

3000 3500 4000 4500 5000

ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW

860 1.05 1.40 1.31 0.85 1.58 1.48 0.62 1.80 1.68 0.32 2.05 1.91 - - -

915 1.23 1.55 1.45 1.05 1.76 1.64 0.80 1.98 1.85 0.51 2.23 2.08 0.22 2.48 2.31

950 1.42 1.68 1.57 1.24 1.91 1.78 1.00 2.14 2.00 0.70 2.43 2.27 0.40 2.72 2.54

1000 1.60 1.83 1.71 1.44 2.07 1.93 1.20 2.33 2.17 0.93 2.62 2.45 0.65 2.91 2.72

1050 1.80 1.98 1.84 1.65 2.25 2.10 1.42 2.55 2.37 1.14 2.86 2.67 0.85 3.17 2.96

1090 1.99 2.12 1.97 1.84 2.41 2.24 1.63 2.72 2.54 1.34 3.06 2.86 - - -

MODEL DCG120

- (SIDE DUCT APPLICATIONS)

BLOWER

SPEED,

RPM

CFM

3000 3500 4000 4500 5000

ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW

860 0.92 1.40 1.31 0.67 1.58 1.48 0.39 1.80 1.68 0.02 2.05 1.91 - - -

915 1.10 1.55 1.45 0.87 1.76 1.64 0.57 1.98 1.85 0.21 2.23 2.08 - - -

950 1.29 1.68 1.57 1.06 1.91 1.78 0.77 2.14 2.00 0.40 2.43 2.27 0.04 2.72 2.54

1000 1.47 1.83 1.71 1.26 2.07 1.93 0.97 2.33 2.17 0.63 2.62 2.45 0.29 2.91 2.72

1050 1.67 1.98 1.84 1.47 2.25 2.10 1.19 2.55 2.37 0.84 2.86 2.67 0.49 3.17 2.96

1090 1.86 2.12 1.97 1.66 2.41 2.24 1.40 2.72 2.54 1.04 3.06 2.86 - - -

NOTES: Blower performance includes a wet evaporator coil, 2" filters and the maximum number of heat exchangers.

Refer to Table 7 for the resistance of the unit accessories.

ESP = External Static Pressure available for the supply and return air duct sytem. All internal unit resistances have been deducted from the total static pressure of the blower.

MODEL DCG120

- (BOTTOM DUCT APPLICATIONS)

= Larger Horsepower Alternate Motor Required.

530.18-N10Y

Unitary Products Group 11

Loading...

Loading...