The “TH1" closes, the draft motor control ”DMC or ETD" is

energized. The “DMC” power contact closes which energizes

the line voltage draft motor. As the speed of the draft motor

reaches approximately 2500 RPM, the centrifugal switch

contact located on the end of the draft motor shaft closes to

power the ignition control “IC”.

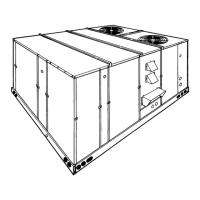

After 15 seconds, the “IC” will start the ignitor sparking and will

open the redundant valve located inside the main gas valve

“GV” to allow a flow of gas to only the carryover tube. See Figure

11. Only after the pilot flame has been ignited and the presence

of pilot flame detected at the “IC” by a signal sent back through

the flame sensor is sparking terminated and the main gas valve

opened.

Gas flows into each of the main burners and is ignited from the

carryover tube flame.

If “IC” fails to detect a pilot flame, it will continue to try for a

maximum of 85 seconds to ignite the pilot tube. If the pilot flame

is not detected, then “IC” will soft lock out for 5 minutes. If the

pilot flame is not detected after 16 retries, then “IC” will hard

lock out the first stage furnace operation until 24V power is

removed from the module either at the unit or by resetting the

room thermostat.

At the same time power was supplied to the “DMC”, a parallel

circuit activates “BT” which closes “BT-1” after approximately

16 seconds and energizes “K5" which closes ”K5-2" and starts

the blower by energizing “M3”.

When “TH2" closes calling for second stage heating, it

energizes ”W2" on the gas valve “GV” directly.

When the heating cycle is complete, “TH-1" opens

de-energizing the ”DMR" and “IC”, thus closing the redundant

and main gas valves. The blower motor continues to run

(approximately 45 seconds after the furnace is shut down) until

“TDR” opens de-energizing the “K5" and ”3M" relays.

SAFETY CONTROLS

The control circuit includes the following safety controls:

1. Limit Control (LS). This control is located inside the heat

exchanger compartment and is set to open at the

temperature indicated in the Limit Control Table. It resets

automatically. The limit switch operates when a high

temperature condition, caused by inadequate supply air

flow occurs, thus shutting down the ignition control and

closing the main gas valve and energizing the blower.

2.

Centrifugal Switch (CS). If the draft motor should fail, the

centrifugal switch attached to the shaft of the motor pre-

vents the ignition control and gas valve from being ener-

gized.

3. Redundant Gas Valve. This valve is an integral part of the

main gas valve and is located up stream of the main gas

valve. Should the main gas valve fail in the open position

the redundant valve serves as a back up and shuts off the

flow of gas.

4. Flame Sensor Rod. This sensor rod is located on the far

side of the carryover tube. If the ignition control does not

receive a signal from the flame sensor indicating that the

pilot flame has ignited properly, the main gas valve will not

open. If the flame sensor fails to detect the pilot flame during

operation of the main burners, a signal is sent to the ignition

control to close the main gas valve.

5. Auxillary Limit Switch (AUX) This control is located insdie

thehet exchanger compartment and is set toopen a at

180

°

F. It is a manual reset switch. If Aux limit trips then the

primary limit has not functioned correctly. Replace the

primary limit.

6. Rollout Switch. This switch is located in the burner

vestibule. In the event of a sustained main burner flame

rollout, it shuts off the ignition control and closes the main

gas valve.

HEAT ANTICIPATOR SETPOINTS

It is important that the anticipator setpoint be correct. Too high

of a setting will result in longer heat cycles and a greater

temperature swing in the conditioned space. Reducing the

value below the correct setpoint will give shorter “ON” cycles

and may result in the lowering of the temperture within the

conditioned space.

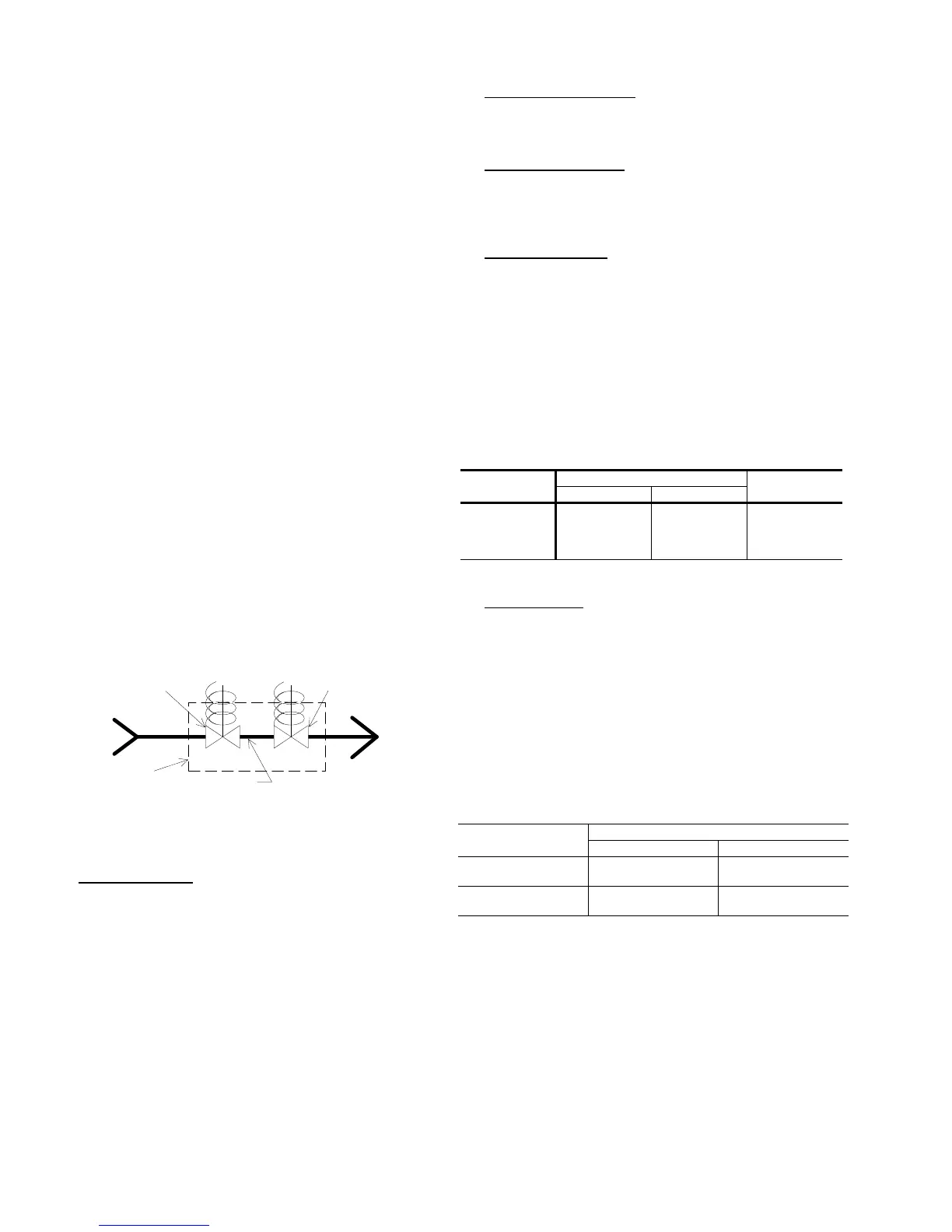

Units

(Tons)

Capacity, MBH

Limit Control

Opens,

°

F

Input Output

7-1/2, 8-1/2

7-1/2, 8-1/2

10, 12-1/2

10, 12-1/2

163

204

204

245

130

163

163

198

180

170

170

170

TABLE 11

- LIMIT CONTROL SETTING

Gas Valve

Anticipator Setpoint

1st Stage 2nd Stage

Honeywell

VR8520

0.50 amp 0.24 amp

White-Rodgers

36C76

0.60 amp 0.10 amp

GAS

VALVE

GAS MAIN

MAIN VALVE

TO MAIN

BURNER

REDUNDANT

VALVE

TO PILOT BURNER

FIG. 11

- GAS VALVE PIPING

530.18-N10Y

14 Unitary Products Group

Loading...

Loading...