290699-YIM-B-0607

Unitary Products Group 15

GAS PIPING

Proper sizing of gas piping depends on the cubic feet

per hour of gas flow required, specific gravity of the gas

and the length of run. “National Fuel Gas Code” Z223.1

(in U.S.A.) or the current Gas Installation Codes CSA-

B149.1 (in Canada) should be followed in all cases

unless superseded by local codes or gas utility require-

ments. Refer to the Pipe Sizing Table 5.

The heating value of the gas may differ with locality.

The value should be checked with the local gas utility.

NOTE: There may be a local gas utility requirement

specifying a minimum diameter for gas piping.

All units require a 1/2” pipe connection at the

entrance fitting.

GAS CONNECTION

The gas supply line can be routed through the knock-

outs located on the front of the unit or through the

opening provided in the unit's base. Refer to Figure 11

to locate these access openings. Typical supply piping

arrangements are shown in Figures 4 and 5. All

shaded items are field-supplied.

If gas supply line is routed through the unit's base

ensure that the burner assembly can be removed for

maintenance without disturbing the supply line. The

supply piping and fittings must lie below the bottom gas

manifold to avoid interference with the burner assem-

bly.

Two grommets are shipped in the blower compartment

(in parts bag taped to the blower housing) of every unit

with gas heat and should be used in the knockouts

when the gas piping penetrates the front of the unit.

After the gas supply piping has been installed, the bot-

tom opening in the unit should be sealed to prevent

water from leaking into the building.

Gas piping recommendations

:

1. A drip leg and a ground joint union must be

installed in the gas piping.

2. When required by local codes, a manual shut-off

valve may have to be installed outside of the unit.

3. Use wrought iron or steel pipe for all gas lines. Pipe

compound should be applied sparingly to male

threads only.

4. All piping should be cleaned of dirt and scale by

hammering on the outside of the pipe and blowing

out the loose dirt and scale. Before initial start-up,

be sure that all of the gas lines external to the unit

have been purged of air.

5. The gas supply should be a separate line and

installed in accordance with all safety codes as

prescribed under “Limitations”. After the gas con-

nections have been completed, open the main

shut-off valve admitting normal gas pressure to the

mains. Check all joints for leaks with soap solution

or other material suitable for the purpose. NEVER

USE A FLAME.

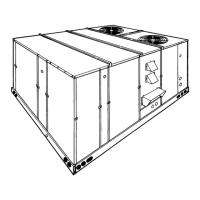

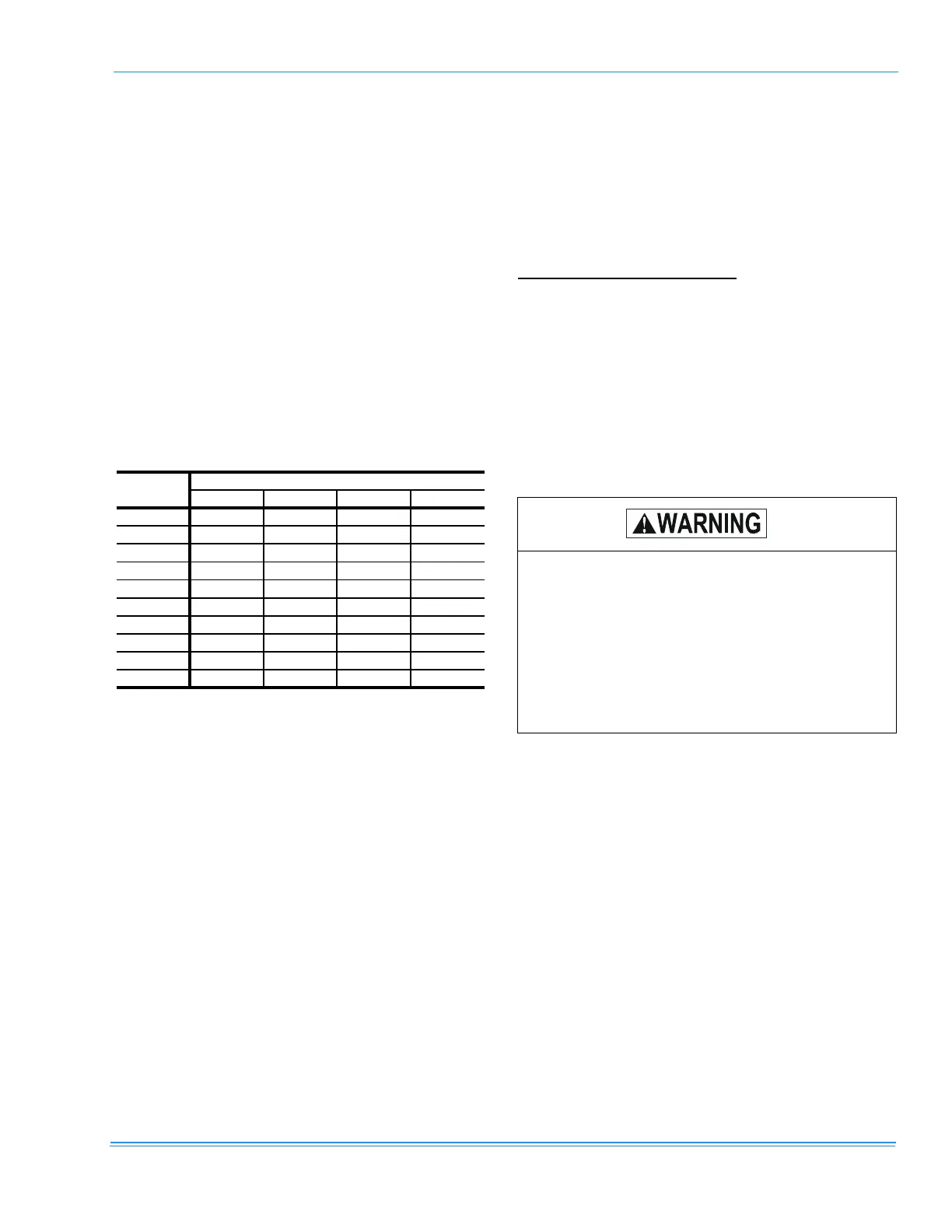

TABLE 5: GAS PIPE SIZING

1/2 in. 3/4 in. 1 in. 1-1/4 in.

10 132 278 520 1,050

20 92 190 350 730

30 73 152 285 590

40 63 130 245 500

50 56 115 215 440

60 50 105 195 400

70 46 96 180 370

80 43 90 170 350

90 40 84 160 320

100 38 79 150 305

NOMINAL IRON PIPE SIZE

LENGTH IN

FEET

Maximum capacity of pipe in cubic feet of gas per hour. (Based upon

a pressure drop of 0.3 inch water column and 0.6 specific gravity gas).

Natural gas may contain some propane. Pro-

pane, being an excellent solvent, will quickly

dissolve white lead or most standard commer-

cial compounds. Therefore, a special pipe

compound must be applied when wrought iron

or steel pipe is used. Shellac base compounds

such as Gaskolac or Stalastic, and compounds

such as Rectorseal #5, Clyde's or John Crane

may be used.

Loading...

Loading...