5402847-UIM-A-0917

12 Johnson Controls Unitary Products

SECTION V: ELECTRICAL POWER

ELECTRICAL POWER CONNECTIONS

Field wiring to the unit must be grounded. Electric wires that are field

installed shall conform to the temperature limitation for 63°F (35°C) rise

wire when installed in accordance with instructions. Refer to Table 7 in

these instructions for specific furnace electrical data.

The residential supply must have a bonded neutral.

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

The furnace shall be installed so that the electrical components are protected from water.

SUPPLY VOLTAGE CONNECTIONS

1. Provide a power supply separate from all other circuits. Install over-

current protection and disconnect switch per local/national electrical

codes. The switch should be close to the unit for convenience in

servicing. With the disconnect or fused switch in the OFF position,

check all wiring against the unit wiring label. Refer to the wiring dia-

gram in this instruction.

2. Remove the screws retaining the wiring box cover. Route the power

wiring through the opening in the unit into the junction box with a

conduit connector or other proper connection. In the junction box

there will be 3 wires, a Black Wire, a White Wire. Connect the

power supply as shown on the unit-wiring label on the inside of the

blower compartment door or the wiring schematic in this section.

The black furnace lead must be connected to the L1 (hot) wire from

the power supply. The white furnace screw must be connected to

neutral. Connect the power supply ground to the green screw

(equipment ground) An alternate wiring method is to use a field pro-

vided 2” (5.1 cm) x 4” (10.2 cm) box and cover on the outside of the

furnace. Route the furnace leads into the box using a protective

bushing where the wires pass through the furnace panel. After mak-

ing the wiring connections replace the wiring box cover and screws.

Refer to Figure 16.

3. The furnace's control system requires correct polarity of the power

supply and a proper ground connection. Refer to Figure 16.

CONTROL WIRING

This furnace can be connected to the wall thermostat and outdoor A/C

or heat pump using either conventional low voltage (24 VAC) thermo-

stat wiring OR using four-wire digital communications wiring. To use

conventional low voltage wiring, see the section below entitled “Con-

ventional Low Voltage Control Wiring”. To use four-wire communica-

tions control wiring, see the section below entitled “Control Wiring using

Communicating Controls”.

The Communicating System consists of several intelligent communicat-

ing components including the Communicating Thermostat Control

(touch-screen wall thermostat), modulating variable speed furnace, air

conditioner (15 and 18 SEER premium air conditioners) or heat pump

(13, 15 and 18 SEER premium heat pumps), which continually commu-

nicate with each other via a four-wire connection called the A-R-C-B.

Commands, operating conditions, and other data are passed continu-

ally between components over the A-R-C-B. See Figure 17. The result

is a new level of comfort, versatility, and simplicity.

CAUTION

Use copper conductors only.

!

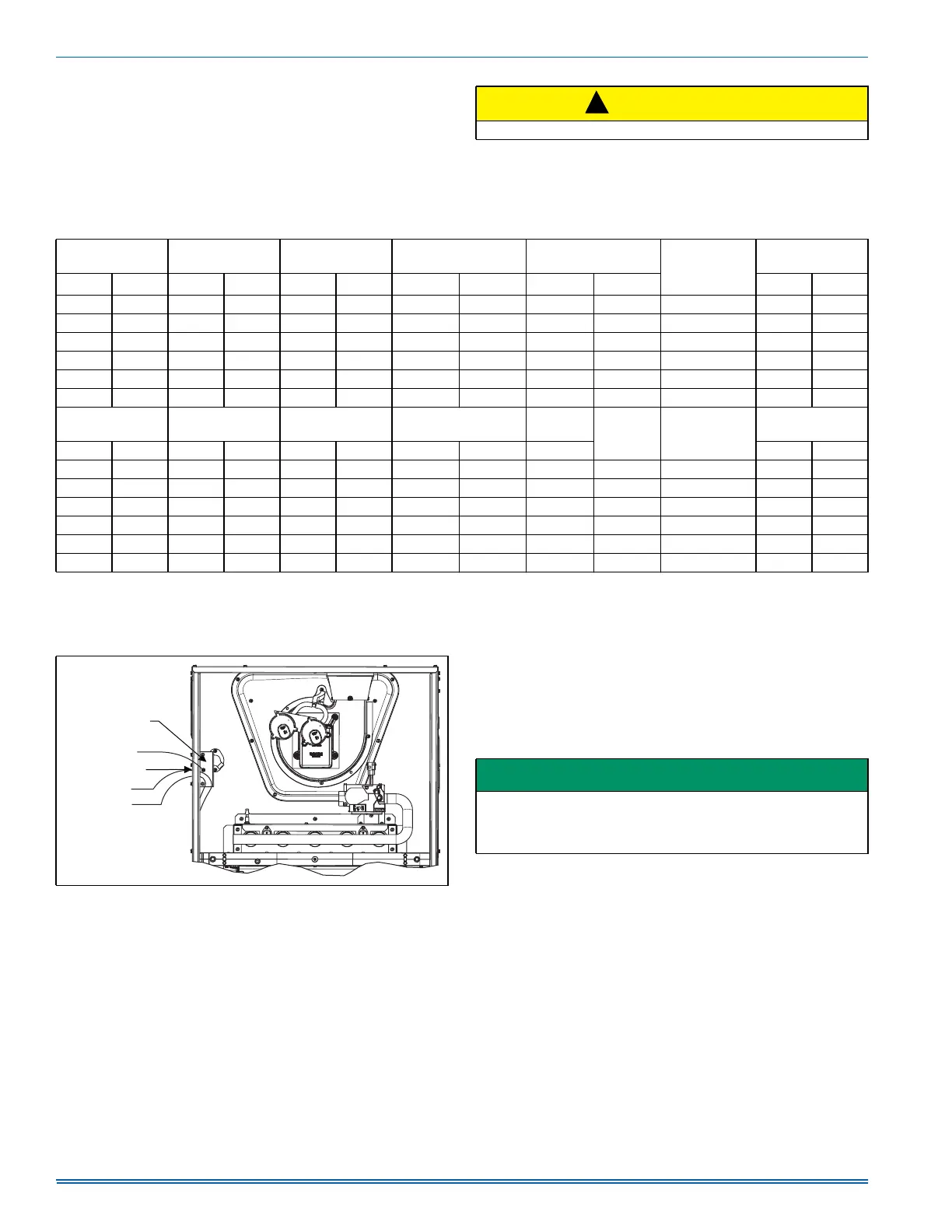

Table 7: Ratings & Physical / Electrical Data

High Fire

Input

Low Fire

Input

High Fire

Output

Low Fire

Output

Nominal

Airflow

Max.

Over-current

Protect

Max. Outlet

Air Temp

MBH kW MBH kW MBH kW MBH kW CFM

m

3

/min

°F °C

60 17.6 39 11.4 47 13.8 31 9.1 1200 34.0

10

190 88

80 23.5 52 15.2 63 18.5 42 12.2 1200 34.0

10

190 88

80 23.5 52 15.2 63 18.5 42 12.2 1600 45.3

15

190 88

100 29.3 65 19.0 80 23.4 52 15.2 1600 45.3

15

190 88

100 29.3 65 19.0 80 23.4 52 15.2 2000 56.6

20

190 88

120 33.7 78 22.9 96 26.9 62 18.3 2000 56.6

20

190 88

High Fire

Air Temp. Rise

Low Fire

Air Temp. Rise

Blower Blower Size

AFUE

Total Unit

Amps

Min. wire Size

(awg) @ 75 ft

one way

Operating

weight

°F °C °F °C HP Amps In. cm % Lbs. Kg.

30-60 17-33 15-45 8-25 1/2 7.7 11 x 8 27.9 x 20.3 80.0 9.0 14 94 43

30-60 17-33 20-50 11-28 1/2 7.7 11 x 8 27.9 x 20.3 80.0 9.0 14 103 47

30-60 17-33 20-50 11-28 3/4 9.6 11 x 10 27.9 x 25.4 80.0 12.0 14 114 52

30-60 17-33 20-50 11-28 3/4 9.6 11 x 10 27.9 x 25.4 80.0 12.0 14 118 54

30-60 17-33 20-50 11-28 1 12.8 11 x 11 27.9 x 27.9 80.0 14.0 12 122 55

30-60 17-33 20-50 11-28 1 12.8 11 x 11 27.9 x 27.9 80.0 14.0 12 129 57

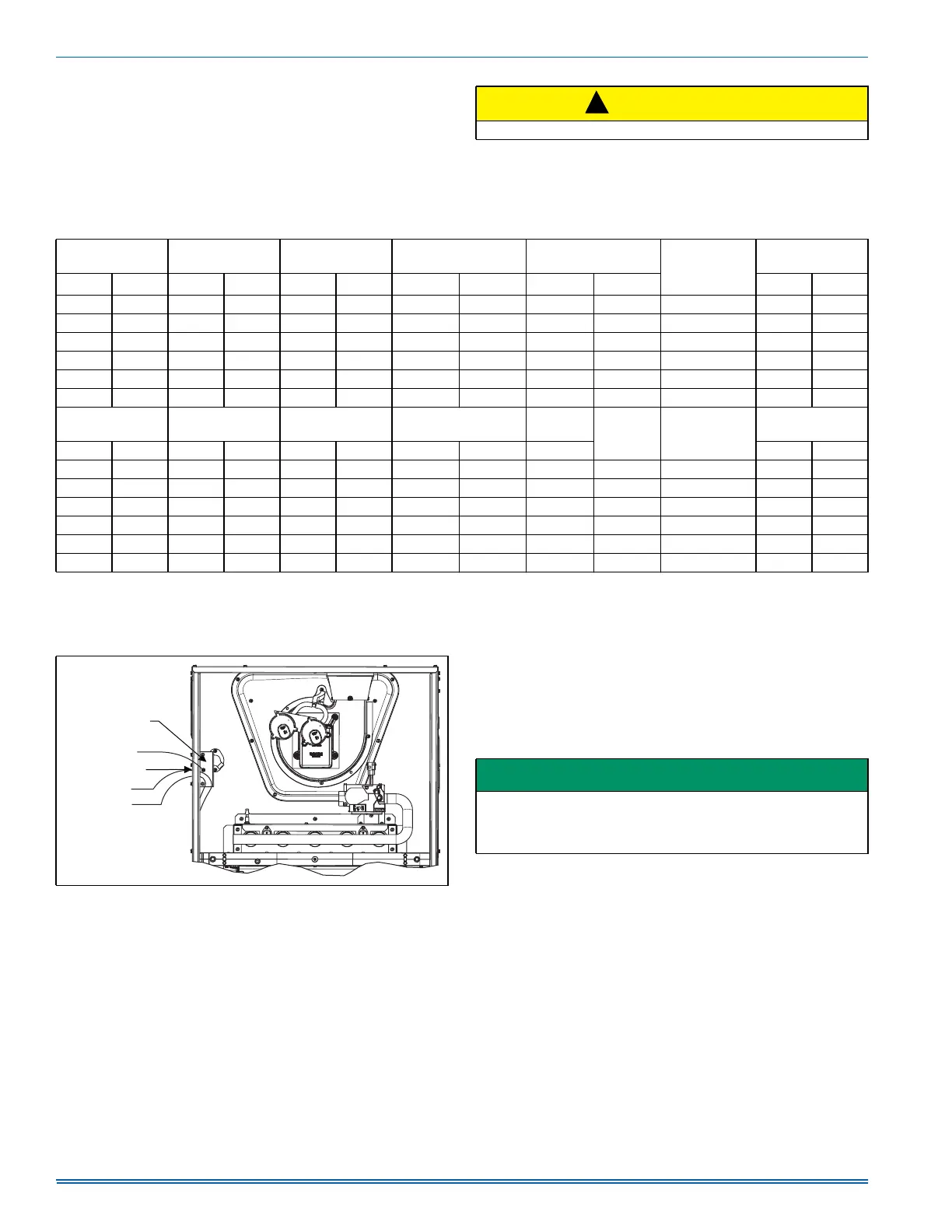

FIGURE 16: Electrical Wiring

Electrical Entry

Junction

Box

L1-Hot

Neutral

Connect ground

lead to screw

BLK

WHT

IMPORTANT

The power connection leads and wiring box may be relocated to the

left side of the furnace. Remove the screws and cut wire tie holding

excess wiring. Reposition on the left side of the furnace and fasten

using holes provided.

Loading...

Loading...