199

JOHNSON CONTROLS

SECTION 8 – UNIT OPERATION

FORM 150.67-NM1

ISSUE DATE: 4/28/2017

8

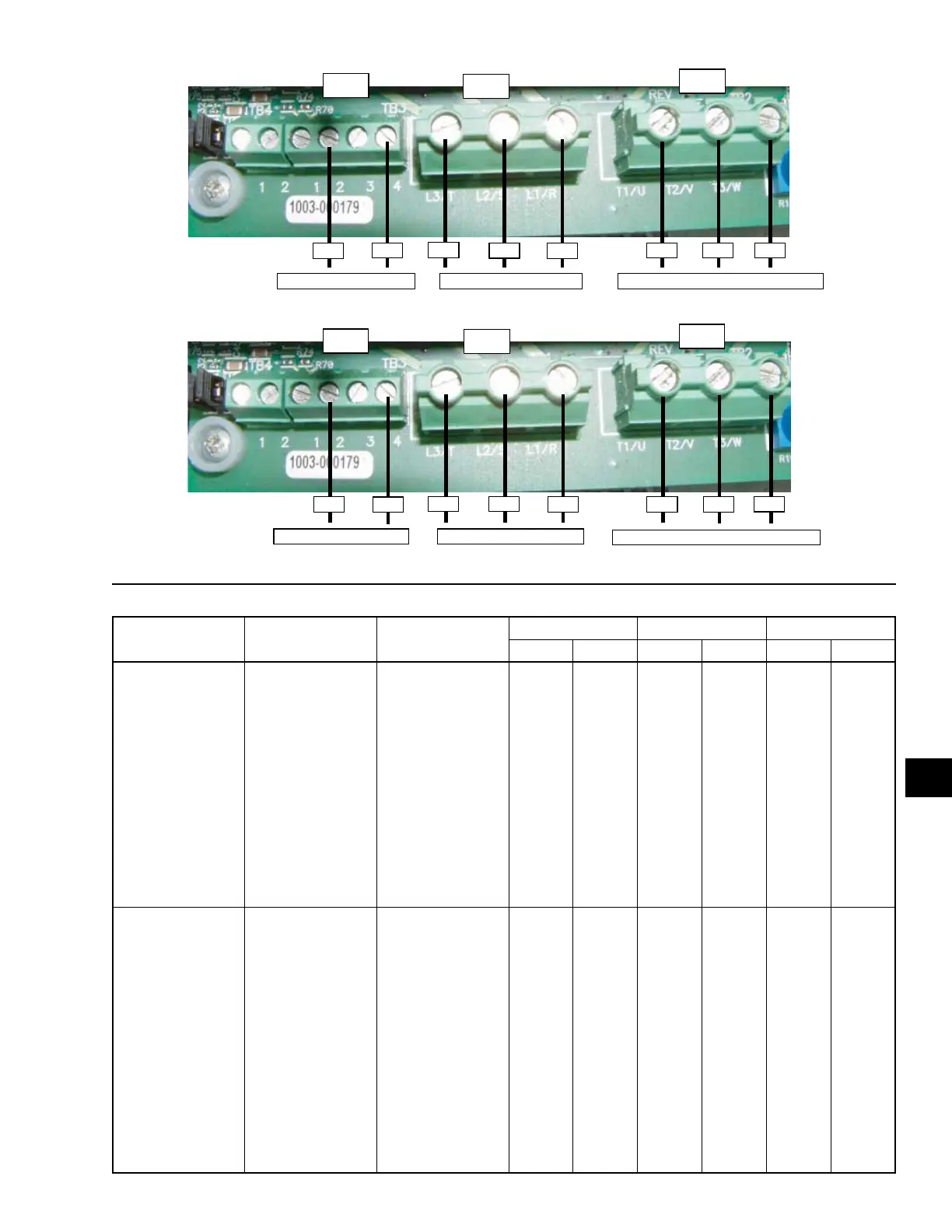

TB3

TB1

TB2

TO PANEL 10M TO FAN #2 (EXISTING HARNES S)TO MICROBOARD (P7)

251250

252

250A

251A252A

WHT

BLK

TB3

TB1

TB2

TO PANEL 10M TO FAN #2 (EXISTING HARNES S)TO MICROBOARD (P7)

251

250

252

250A

251A252A

WHT

BLK

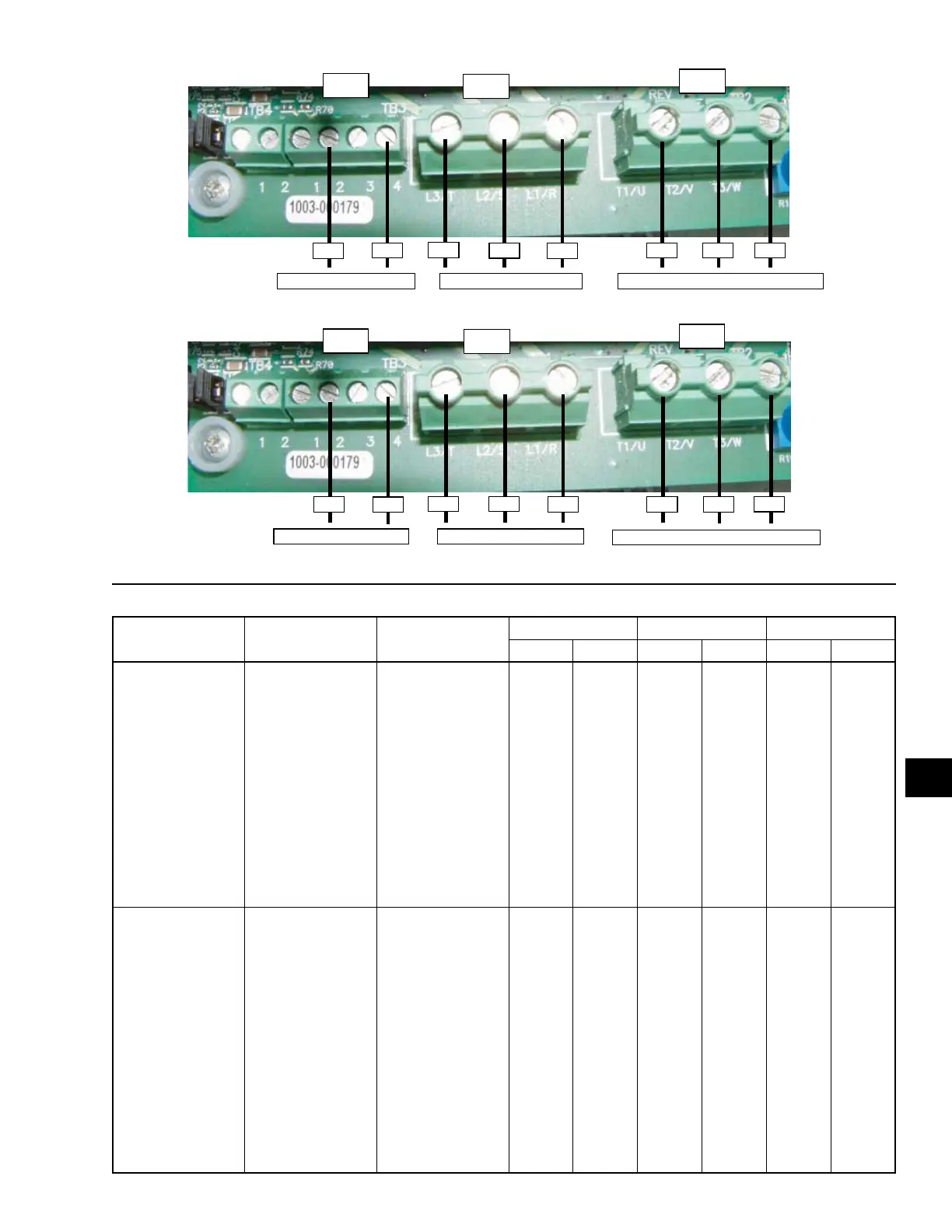

TB3

TB1

TB2

TO PANEL 7M TO FAN #1 (EXISTING HARNESS)

TO MICROBOARD (P4)

151

150

152

150A

151A

152A

WHT

BLK

TB3

TB1

TB2

TB3

TB1

TB2

TO PANEL 7M TO FAN #1 (EXISTING HARNESS)

TO MICROBOARD (P4)

151

150

152

150A

151A

152A

WHT

BLK

FIGURE 58 - INVERTER WIRING

LD11302

TABLE 28 - YCAL0043-0066 VFD LOW AMBIENT OPTION – CONDENSER FAN CONTROL OPERATION

FAN STAGE ON OFF

CONTACTOR MICROBOARD FAN #

SYS 1 SYS 2 SYS 1 SYS 2 SYS 1 SYS 2

1:

VFD CONTROL

(1 FAN

VARIABLE

SPEED)

FAN SPEED

IS A FUNCTION

OF

DISCHARGE

PRESSURE.

WHEN THE

LIQUID LINE

SOLENOID IS

ENERGIZED,

SPEED

INCREASES

WITH PRESSURE

FAN WILL

TURN OFF OR

TURN VERY

SLOWLY WHEN

PRESSURE

DROPS BELOW

260 PSIG.

7M 10M TB7-3 TB10-9 1 2

2:

1 FAN VFD

CONTROL

2ND FAN

FULL SPEED

UNDER

CONTACTOR

CONTROL

425 PSIG,

BOTH FANS

WILL BE

RUNNING FULL

SPEED

DISCHARGE

PRESSURE

< 260 PSIG

(PRESSURE IS

< FAN CONTROL

ON PRESSURE

OF

425 PSIG

MINUS FAN

DIFFERENTIAL

PRESSURE OF

125 PSIG = 300

PSIG)

7M

&

8M

10M

&

11M

TB7-3

AND

TB7-10

TB10-9

AND

TB10-

10

1

&

3

2

&

4

Loading...

Loading...