JOHNSON CONTROLS

198

FORM 150.67-NM1

ISSUE DATE: 4/28/2017

SECTION 8 – UNIT OPERATION

quirements are needed to run the VFD. Figure’s 56 and

57 show the power and control wiring schematically

as well as the actual connections. The VFD controlled

fan will operate whenever the liquid line solenoid on

the respective system is energized.

PROGRAMMING

Condenser fan control type must be programmed un-

der both the OPTIONS and PROGRAM keys when a

VFD is installed on the chiller. Under the OPTIONS

key, FAN CONTROL must be programmed for DIS-

CHARGE PRESSURE CONTROL only. This will as-

sure condenser fan control of the chiller is solely by

discharge pressure, with no ambient control.

Under the PROGRAM key, the FAN

CONTROL ON PRESSURE should

be programmed for 425 PSIG and the

FAN DIFFERENTIAL OFF PRES-

SURE must be programmed for 125

PSIG.

Programming as suggested assures the chiller control

points for the second fan in the fan staging sequence

and the inverter control points are matched for opti-

150A L1 T1 150

151A L2 T2 151

152A L3 T3 152

CONDENSER

FAN NO. 1

SPEED

CONTR.

7M

250A L1 T1 250

251A L2 T2 251

252A L3 T3 252

CONDENSER

FAN NO. 2

SPEED

CONTR.

10M

LD11301

FIGURE 56 - INVERTER POWER WIRING SC

mum control of the fans at reduced ambient tempera-

tures. When the chiller and VFD fan control points are

programmed properly, the fans will operate as outlined

in Table 28.

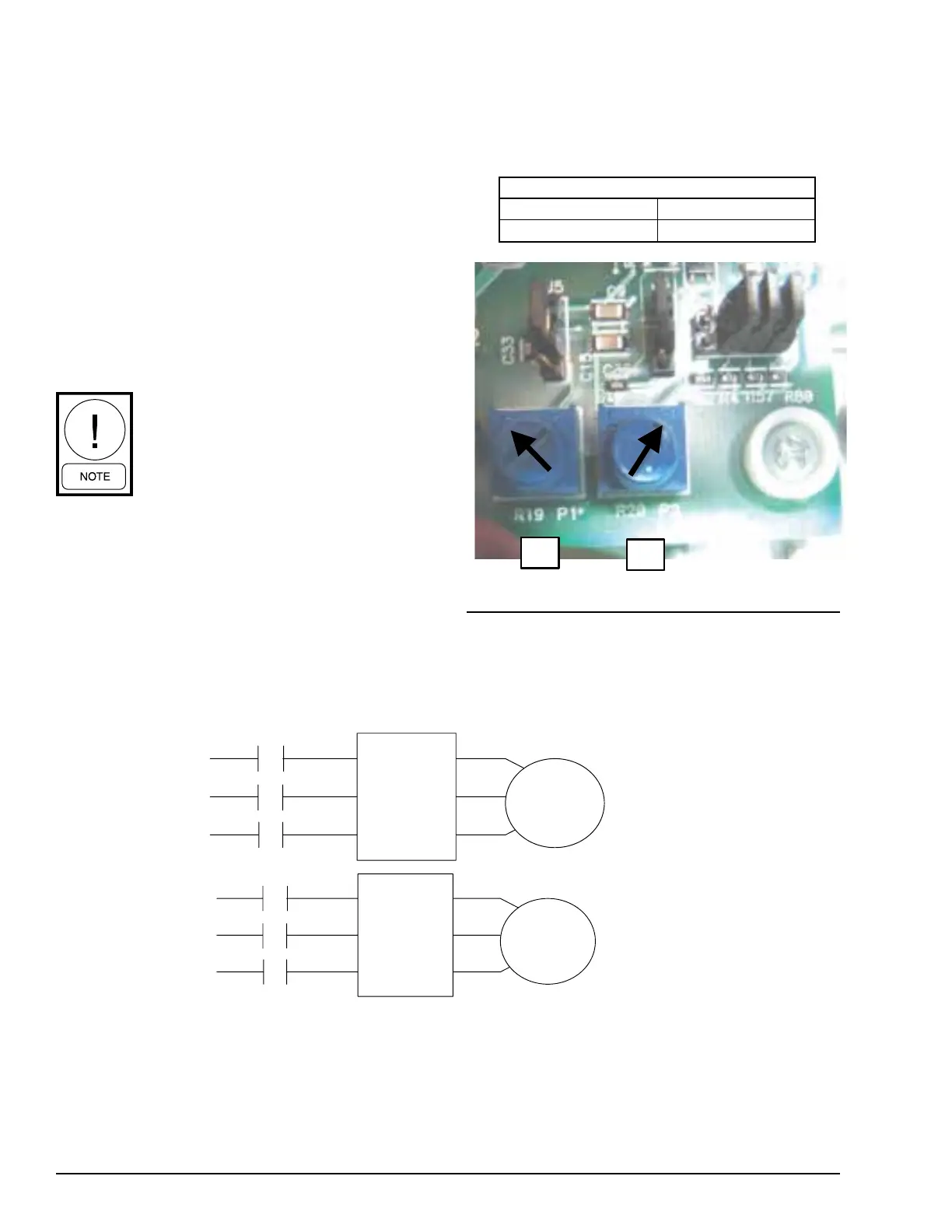

POTENTIOMETER SETTINGS

P1 P2

292 PSI 32 PSI

FIGURE 57 - POTENTIOMETER SETTINGS

LD11300a

Loading...

Loading...