87JOHNSON CONTROLS

FORM NO.: 6U6K-B01E-NB-EN

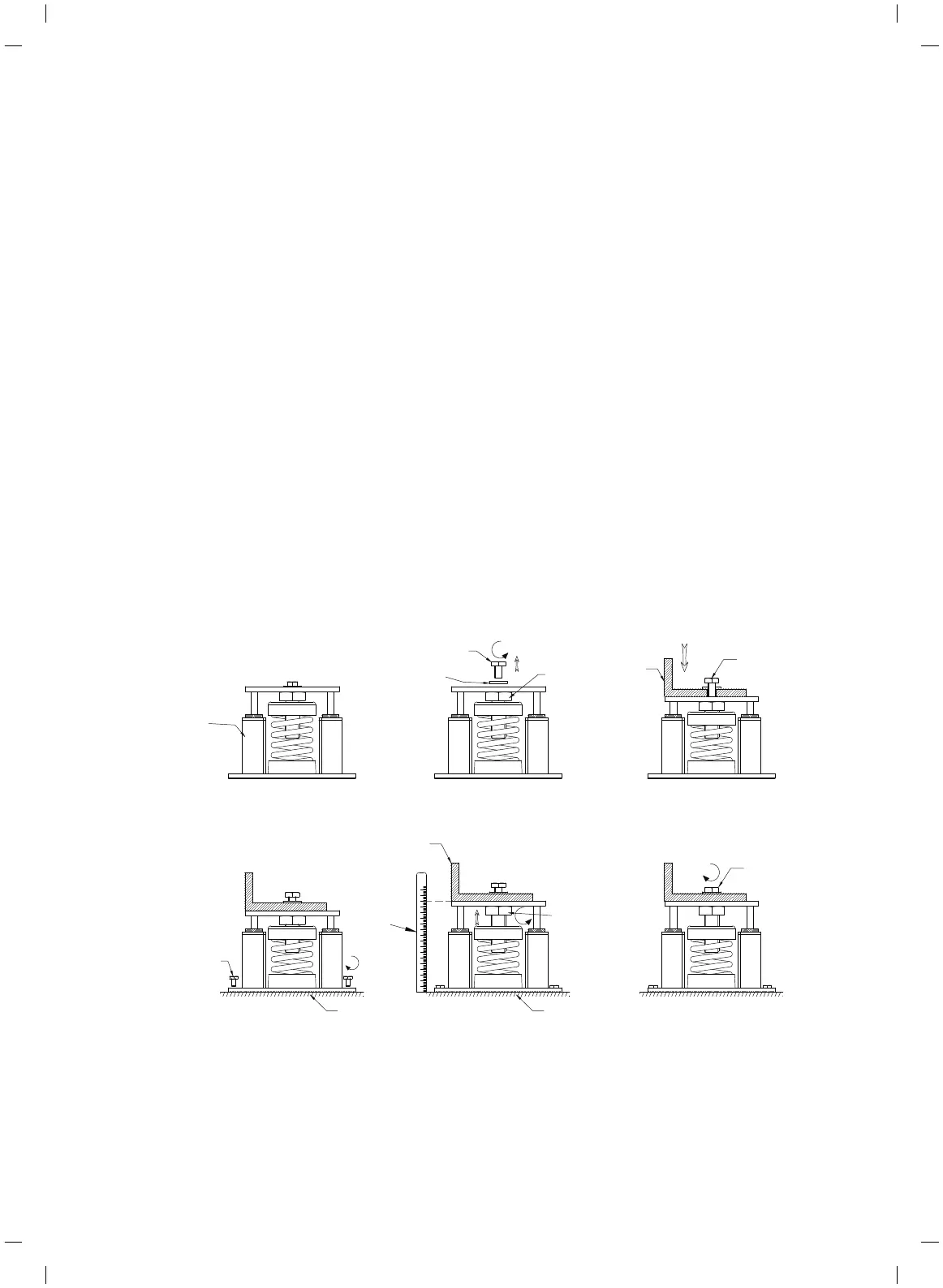

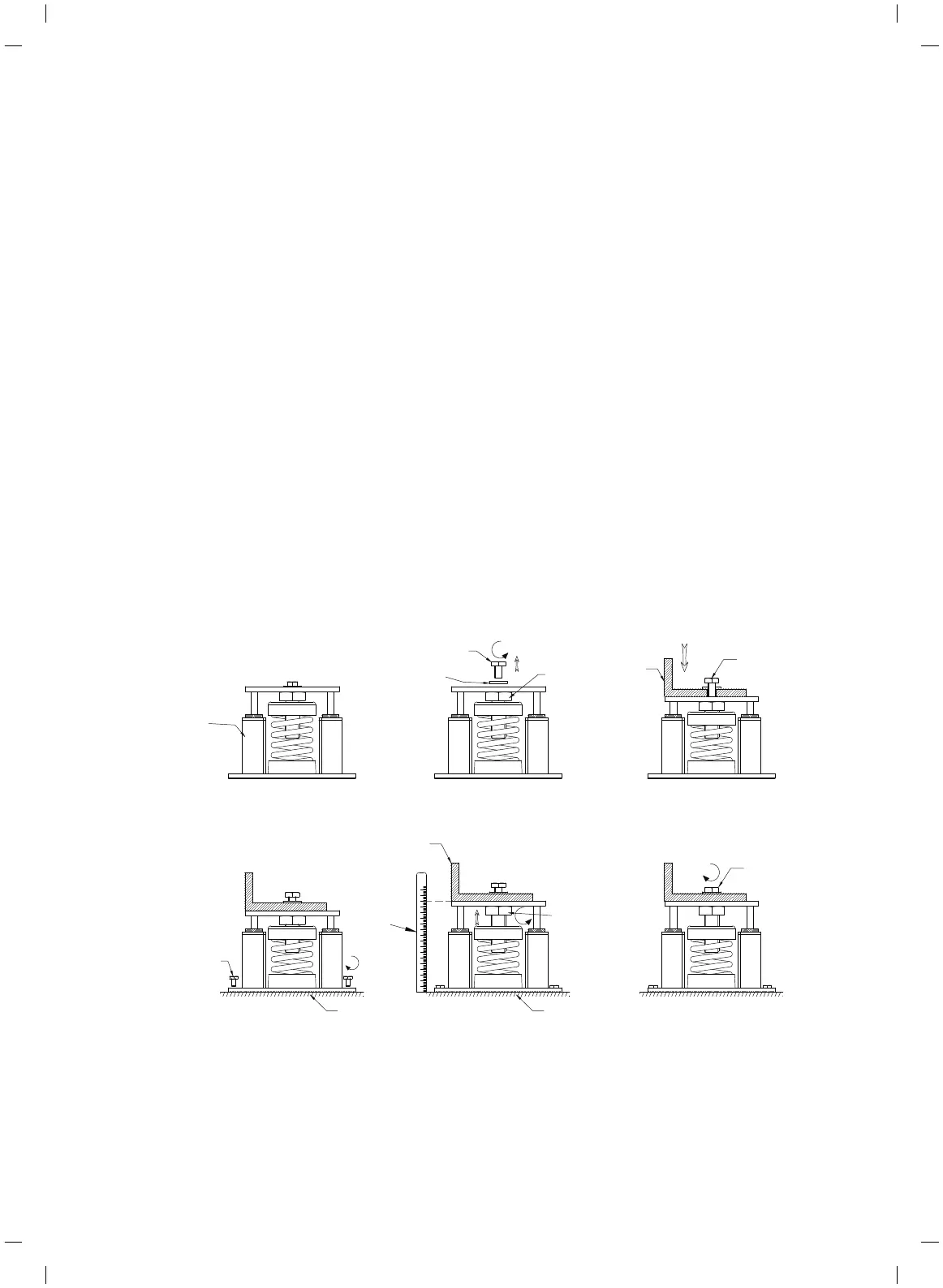

TWO INCH DEFLECTION SPRING ISOLATOR INSTALLATION

AND ADJUSTMENT

Installation Instructions

1.Read instructions in their entirety before beginning

installation.

2.Isolators are shipped fully assembled. Make sure the AVM

types are correct (print codes and adhesive labels) and match

each load point with corresponding isolators.

3.Twist off the xing bolt and washer anticlockwise.

4.Set isolators on oor. Ensure that all isolator centerlines match

the equipment mounting holes. The isolator base be installed on

a level surface. Leveling all isolator bases to the same elevation

(1/4-inch maximum difference can be tolerated).

5.Place equipment on top of isolators making sure that mounting

holes of the equipment line up with isolator installation holes.

6.Place the xing bolt and washer but do not tighten them.

7.Ensure the verticality of the isolators and use bolts to x the

bases of the isolators to the level oor. Use the same torque to

fasten the bolts.

8.The adjustment process can only begin after the equipment or

machine is at its full operating weight.

9.Measure the height of the housing. Adjust each isolator in

sequence by turning adjusting bolt. Repeat this procedure on all

isolators, one at a time.

10.Fine adjust isolators to level equipment. Fasten the nut and

xing bolt.

11.Installation is complete.

Load label

Adjusting

bolt

Fixing bolt

Washer

Level basement

Adjusting

bolt

Unit

550 550 550

Unit

Fixing

bolt

550

Level basement

550 550

Fixing

bolt

Lock

Bolt

Ruler

Step 1

Step 2

Step 4

Step 5

Step 3

Step 6

SECTION 5 – TECHNICAL DATA

Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz

Loading...

Loading...