17

5 Installation

Careful and professional installation of the switch-

gear is one of the fundamental conditions of

trouble-free circuit-breaker operation.

• Install the mechanism enclosure in the panel

without tension or distortion, inserting dished

washers below the nuts or bolt heads at each of

the four mounting points (dependent on the

order).

• Connect the main terminals without any perma-

nent tension or pressure forces, exerted for

example by the conductor bars.

• When connecting the conductor bars, the bolts

must be inserted to the depth shown on the

dimensional drawing.

• Take account of any tested terminal zone.

• Use DIN bolts of tensile class 8.8, fastening

conductor bars together with dished washers.

• Make a short-circuit proof connection between

the PE conductor and the main earthing bar in

the switchgear, using contact washers.

• Remove any dirt. See also section 7.3.1.

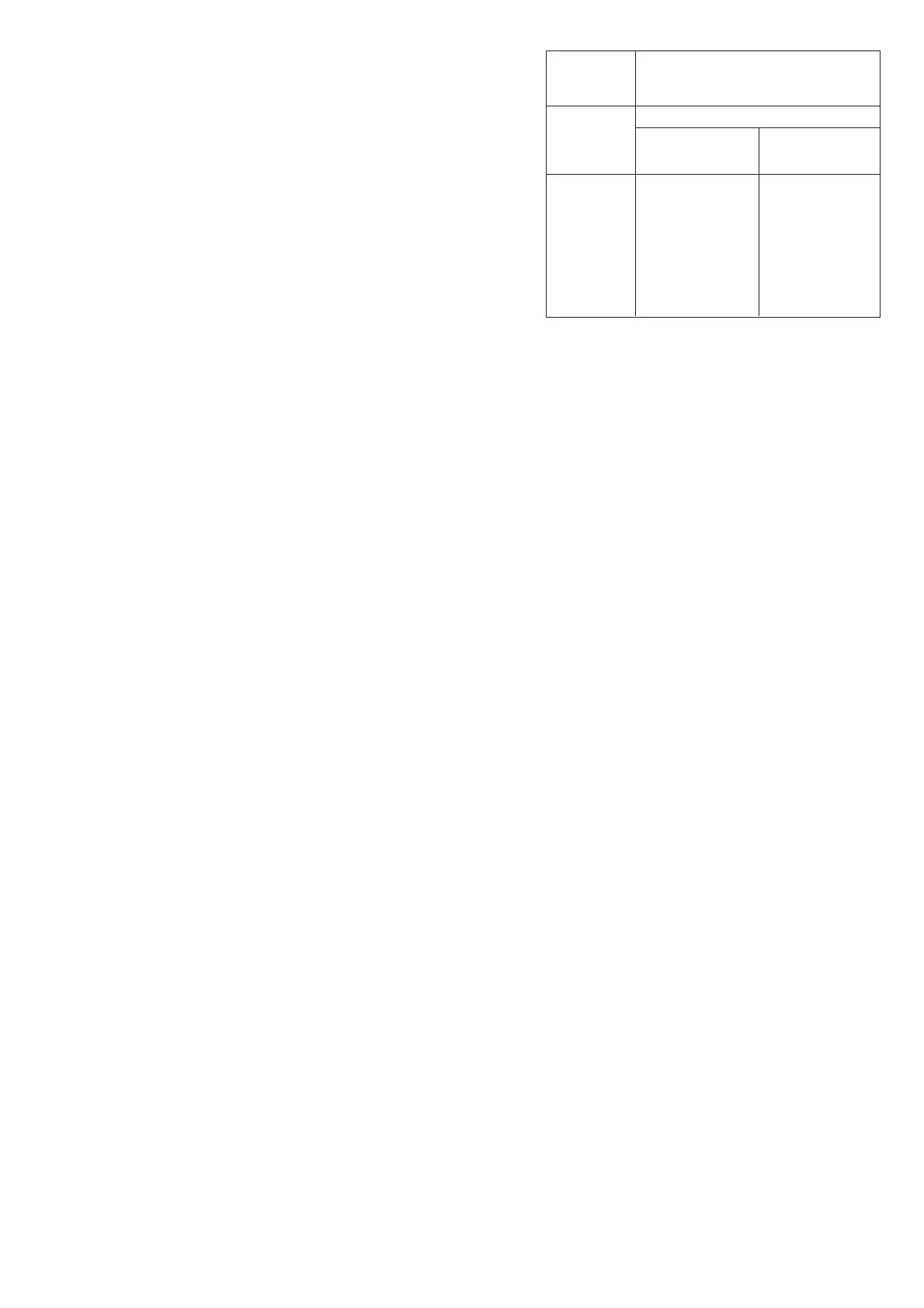

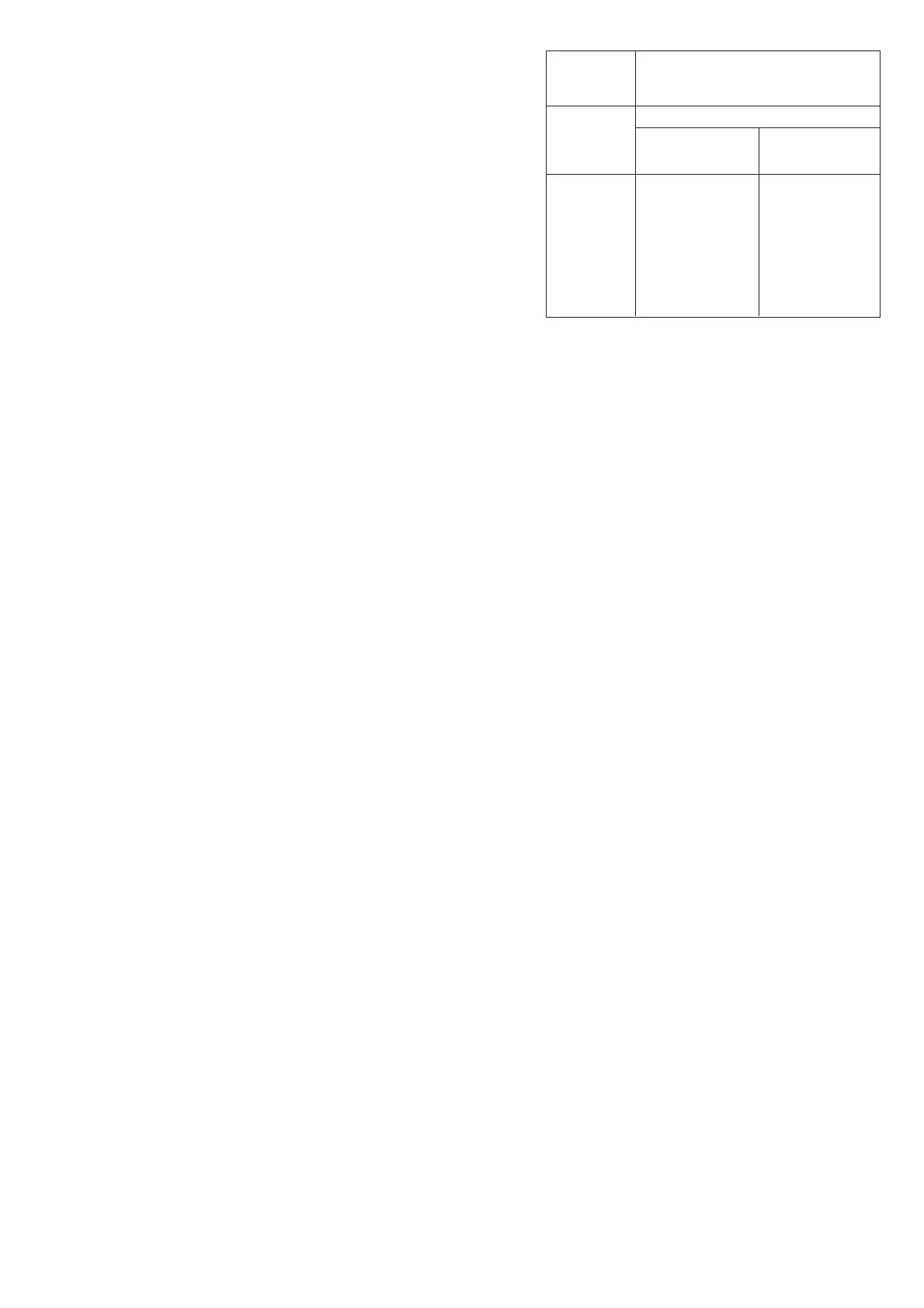

Recommended

rated tightening torque

1)

Nm

Lubricant

2)

Thread size without Oil

(dry) or grease

M 6 10.5 4.5

M 8 26 10

M10 50 20

M12 86 40

M 16 200 80

1)

• Rated tigthening torques for fasteners without

ubrication are based on the thread friction coefficient

0.14 (the actual values of which are subject to

unavoidable, in some cases not insignificant, spread).

• Rated tigthening torques for fastener with lubrication

in accordance with DIN 43673.

2)

Thread and contact face of head lubricated.

Take account of any tightening torques which deviate

from the general table (e.g. for contact systems or device

terminals) as stated in the detailed technical documentation.

It is recommended that the threads or head contact

surfaces of the bolts be lightly oiled or greased, so as to

achieve a precisely defined rated tightening torque.

Loading...

Loading...