25

Instruction book

9096 3313 00

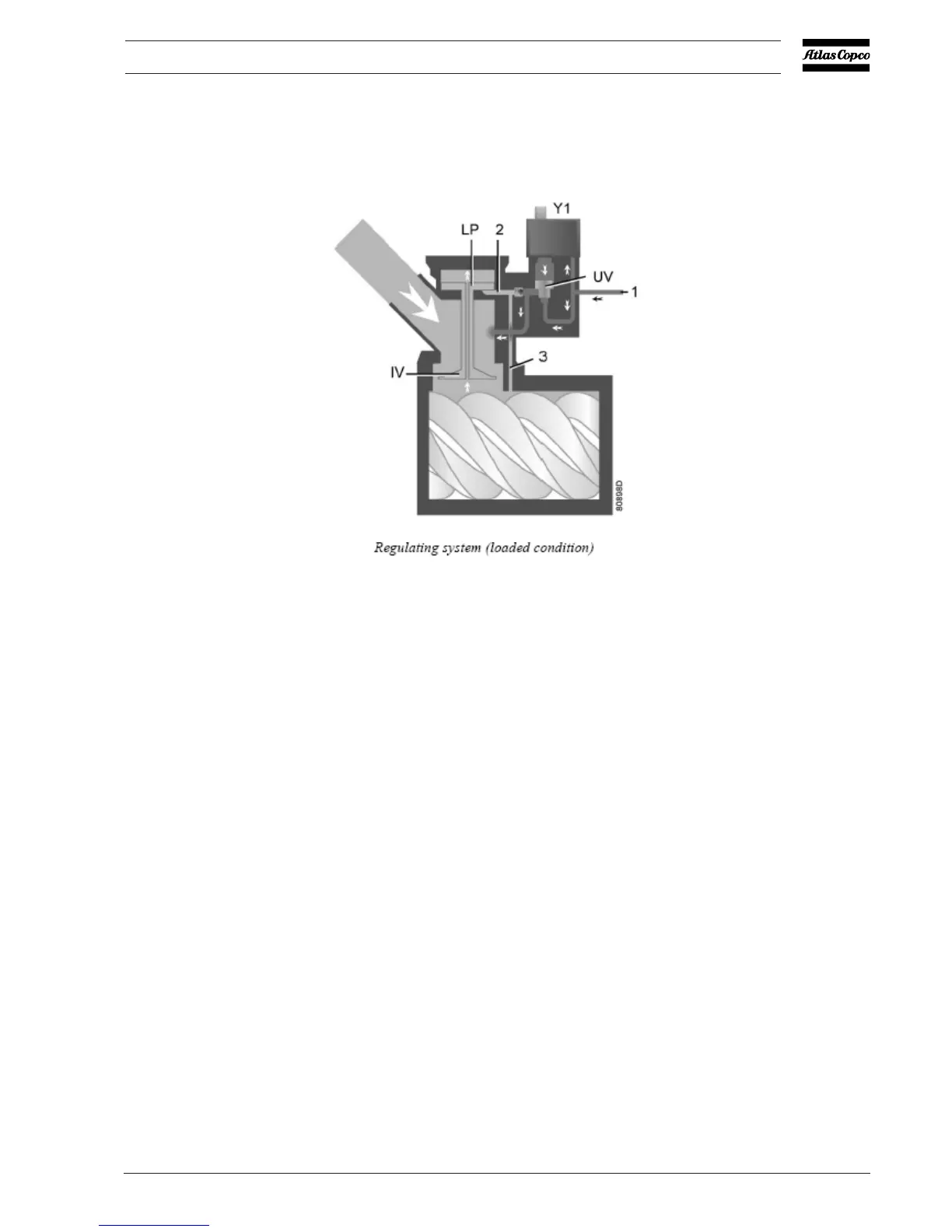

2.6 Regulating system

Flow diagram

Loading

When the net pressure is below the loading pressure, solenoid valve (Y1) is energised. Results:

• The space above unloading valve/blow-off valve (UV) is connected with the oil separator tank

pressure(1) via the solenoid valve.

• Unloading valve/blow-off valve (UV) moves downwards, closing off the connection to channels (2)

and(3).

• Underpressure from the compressor element causes loading plunger (LP) to move downwards and

inletvalve (IV) to open fully.

Air delivery is 100%, the compressor runs loaded.

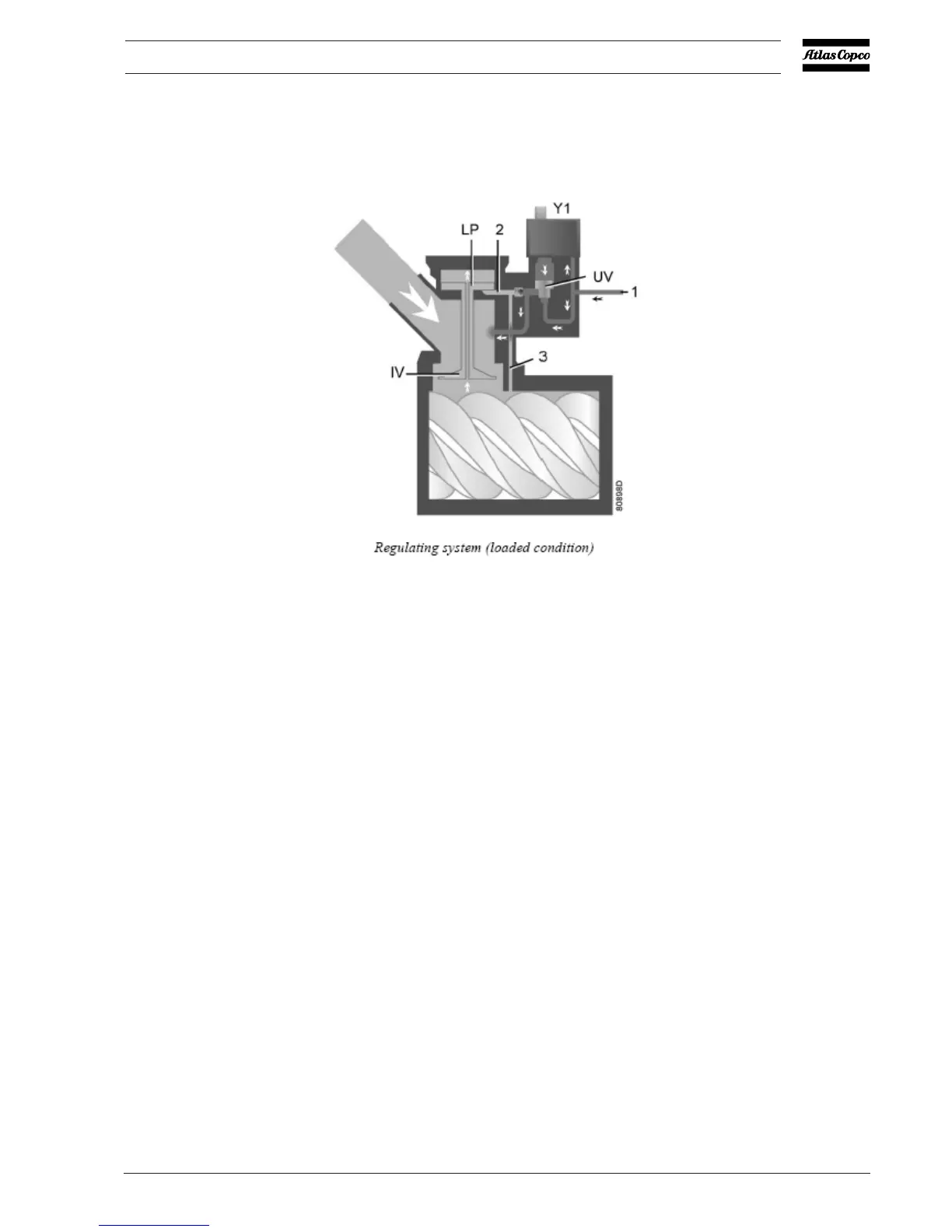

Unloading

If the air consumption is less than the air output of the compressor, the net pressure increases. When the

netpressure reaches the unloading pressure, solenoid valve (Y1) is de-energised. Results:

• The pressure above unloading valve/blow-off valve (UV) is released to atmosphere and the space

abovevalve (UV) is no longer in connection with the oil separator tank pressure (1).

• Unloading valve/blow-off valve (UV) moves upwards, connecting the oil separator tank pressure (1)

withchannels (2) and (3).

• The pressure in channel (2) causes the loading plunger (LP) to move upwards, causing inlet valve (IV)

toclose, while the pressure is gradually released to atmosphere.

• The pressure in the separator tank stabilises at low value. A small amount of air is kept drawn in

toguarantee a minimal pressure, required for lubrication during unloaded operation.

Air output is stopped, the compressor runs unloaded.

Loading...

Loading...