5.4 Oil, filter and separator change

Important

Never mix oils of different brands or types.

If the compressor is exposed to external pollutants, is being used at high temperatures (oil

temperature above 90˚C / 194˚F) or is being used under severe conditions, it is advisable to

change the oil more frequently. Consult Atlas Copco.

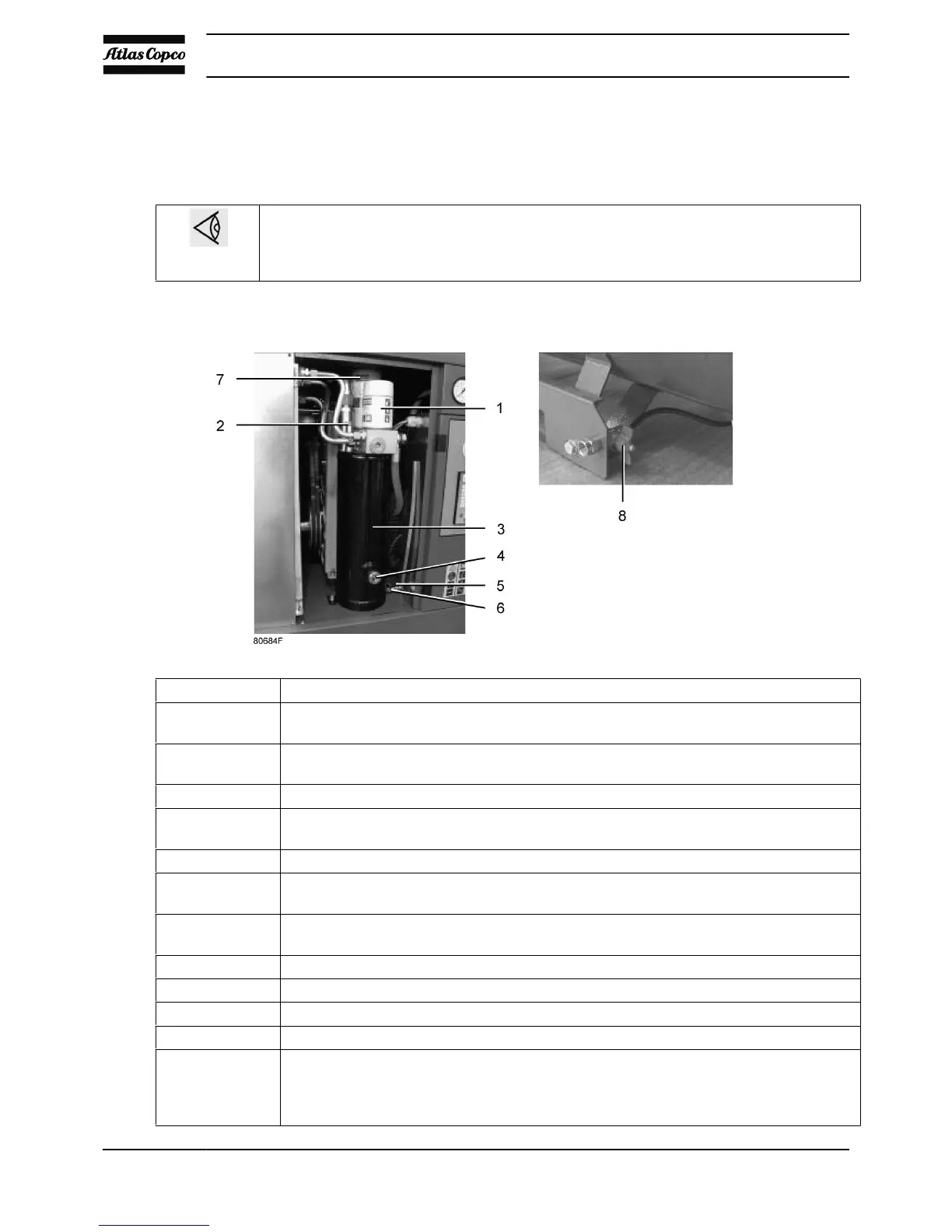

Location of oil filter and separator

Step Action

1 Run the compressor until warm. Stop the compressor, close the air outlet valve and switch

off the voltage. See Stopping.

2 Depressurise the compressor by unscrewing filler plug (2) one turn to permit any pressure

in the system to escape. Remove the plug after the system is depressurised.

3 Depressurise the air receiver by opening drain valve (8).

4 Remove plug (5), drain the oil by opening drain valve (6). Close the valve and refit the plug

after draining. Deliver the drained oil to the local oil collection service.

5 Remove oil filter (7) and separator (1). Clean the seats on the manifold.

6 Oil the gaskets of the new filter and separator and screw them into place. Tighten firmly

by hand.

7 Fill oil separator/tank (3) with oil until the level reaches the middle of sight-glass (4). Ensure

no dirt gets into the system.

8 Refit and tighten filler plug (2).

9 Close drain valve (8) of the air receiver.

10 Run the compressor for a few minutes.

11 Stop the compressor and wait a few minutes to allow the oil to settle.

12 Check the oil level. Add oil if necessary.

If the oil level is too low, depressurise the system by unscrewing filler plug (2) one turn to

permit any pressure in the system to escape. Depressurise the air receiver by opening

drain valve (8).

Instruction book

52 2920 7054 00