Hydraulic oil

Normally the type of hydraulic oil the carrier is using

also works for the hydraulic breaker. When a

hydraulic breaker is connected to the carrier, the

hydraulic oil will get dirty faster. Check and follow

the carrier's instructions for changing oil and oil filter.

It is common to change the oil filter more frequent

when a hydraulic breaker is installed.

SB hydraulic breakers are equipped with an oil

drainage plug to drain all oil before dismounting. This

is to reduce the risk of spilling oil.

NOTICE When the SB breaker is delivered it

contains some mineral based hydraulic oil. Before

connecting to the carrier's hydraulic system, check

which type of hydraulic oil the carrier is using. Mixing

different types of hydraulic oil may destroy the

lubrication quality which can lead to machine

damage.

In order to protect the environment we recommend

the use of biologically degradable hydraulic oil.

Viscosity

15-100 cStViscosity (permitted)

NOTICE Always use clean oil and filling equipment.

Assembly

Circulate the hydraulic oil before connecting the

hydraulic breaker. This is to make sure that the

hydraulic oil is clean. Use the same routine when

changing the hydraulic oil hose. For further

information see "Hydraulic oil".

1. Connect the pressure and return hoses.

2. Run the hydraulic oil through the carrier's oil filter

for approximately 3 minutes to make sure that

the hoses are clean.

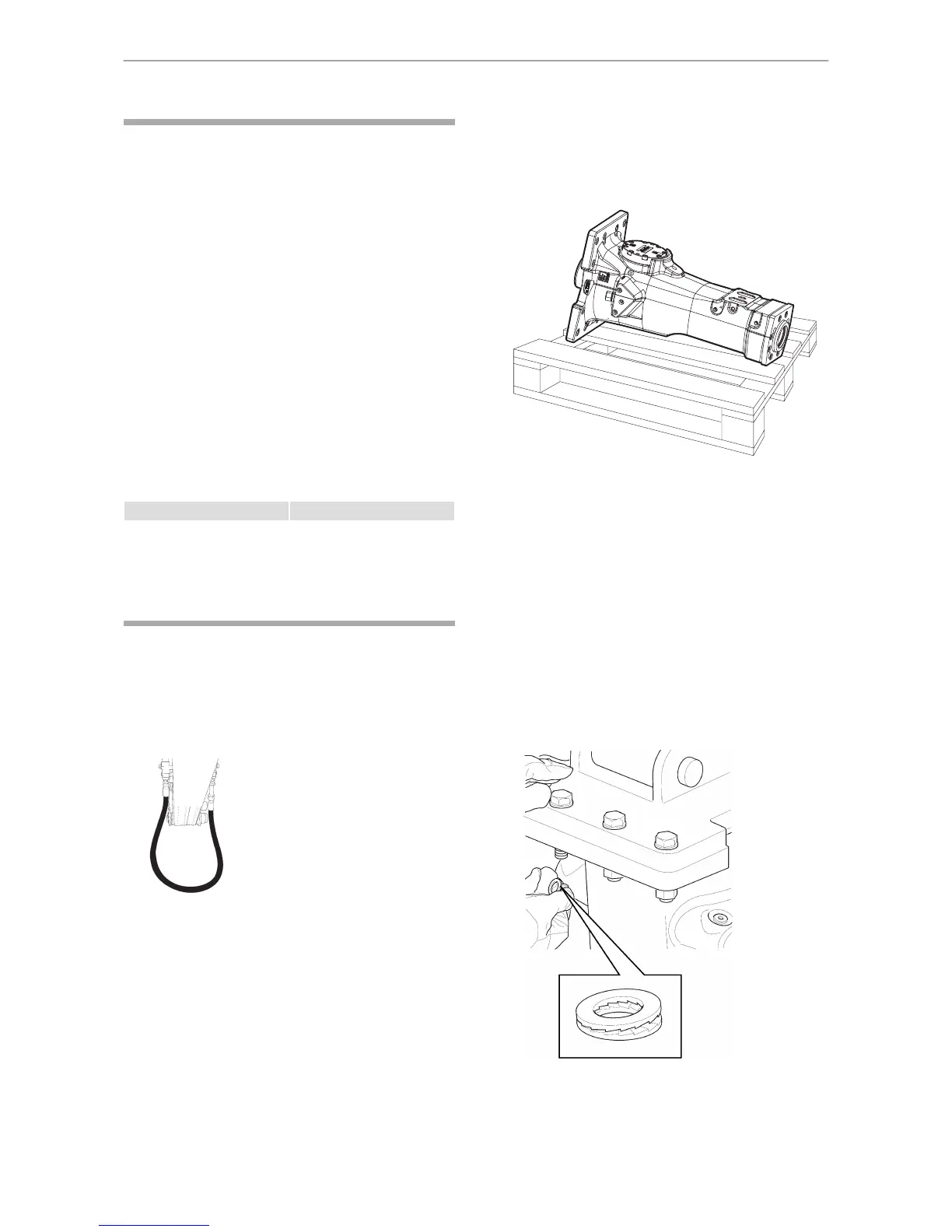

Preparation

♦

Place the breaker in a position where it is easy

and safe to mount the adapter plate.

NOTICE Mount the breaker so that the

accumulator faces the operator's cabin, to reduce

the risk of accumulator damage.

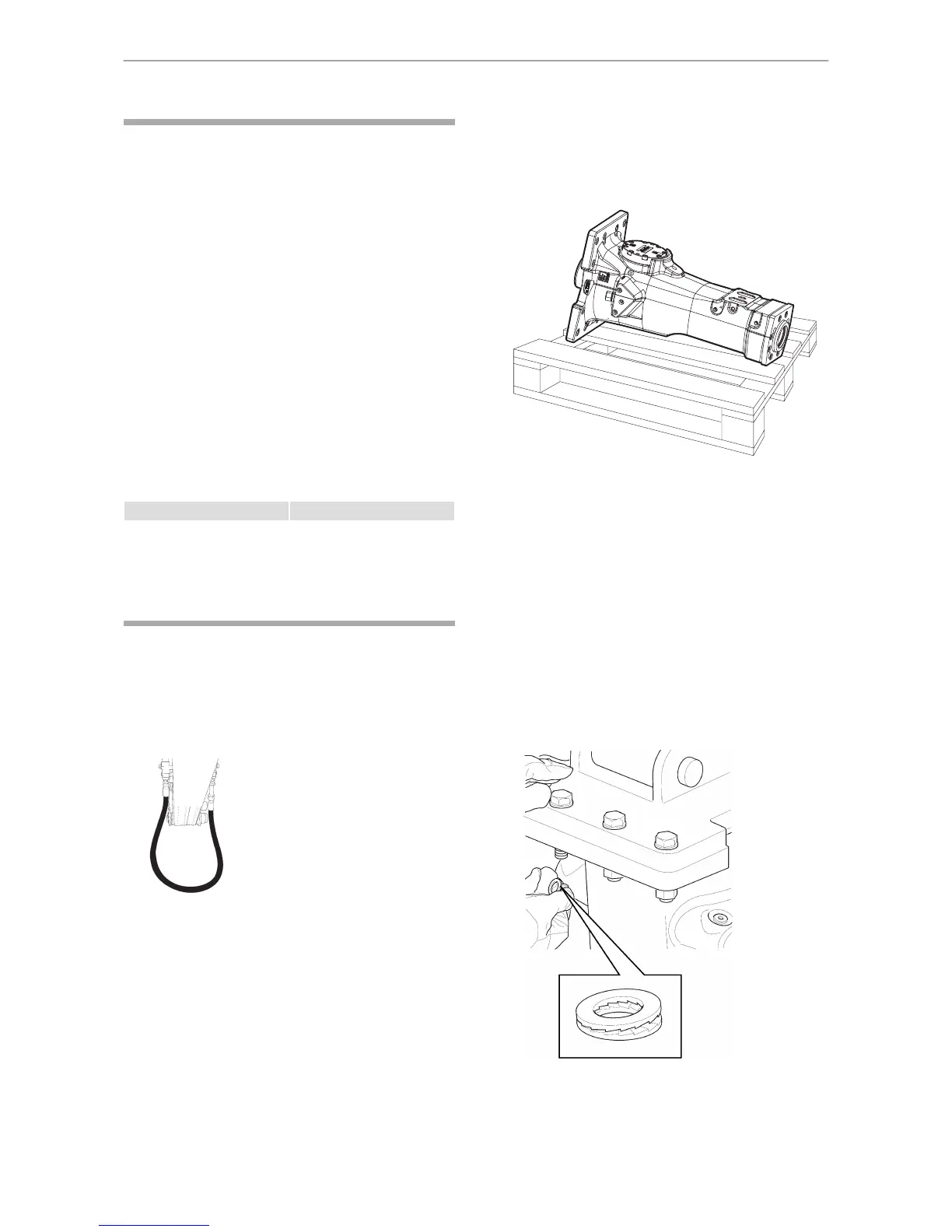

Mounting the adapter plate

1. Place the adapter plate on the hydraulic breaker.

2. Place NYLOK BLUE PATCH™ (Known as

TUF-LOK

®

in Europe) screws through all bore

holes and fit nuts to the screws.

If NYLOK BLUE PATCH™ (Known as TUF-LOK

®

in Europe) screws are not available we

recommend using NORD-LOCK

®

washers under

bolts and nuts. (NYLOK BLUE PATCH is a

trademark of Nylok Corporation. TUF-LOK is a

registered trademark of Nylok Corporation in

Europe. NORD-LOCK is a registered trademark

of Nord-Lock International AB.)

3. Tighten the nuts, see the tightening torque in the

table below.

© 2015 Construction Tools PC AB | No. 9800 1273 01d | 2015-12-30

Original instructions

14

SB 702, 1102Safety and operating instructions

Loading...

Loading...