4. Clean and lubricate the bushing plentifully.

NOTICE When mounting a new working tool, it

is especially important to lubricate plentifully.

5. Mount the working tool, use a lifting strap to

reduce the risk of personal injury.

6. Rotate the working tool to spread the grease.

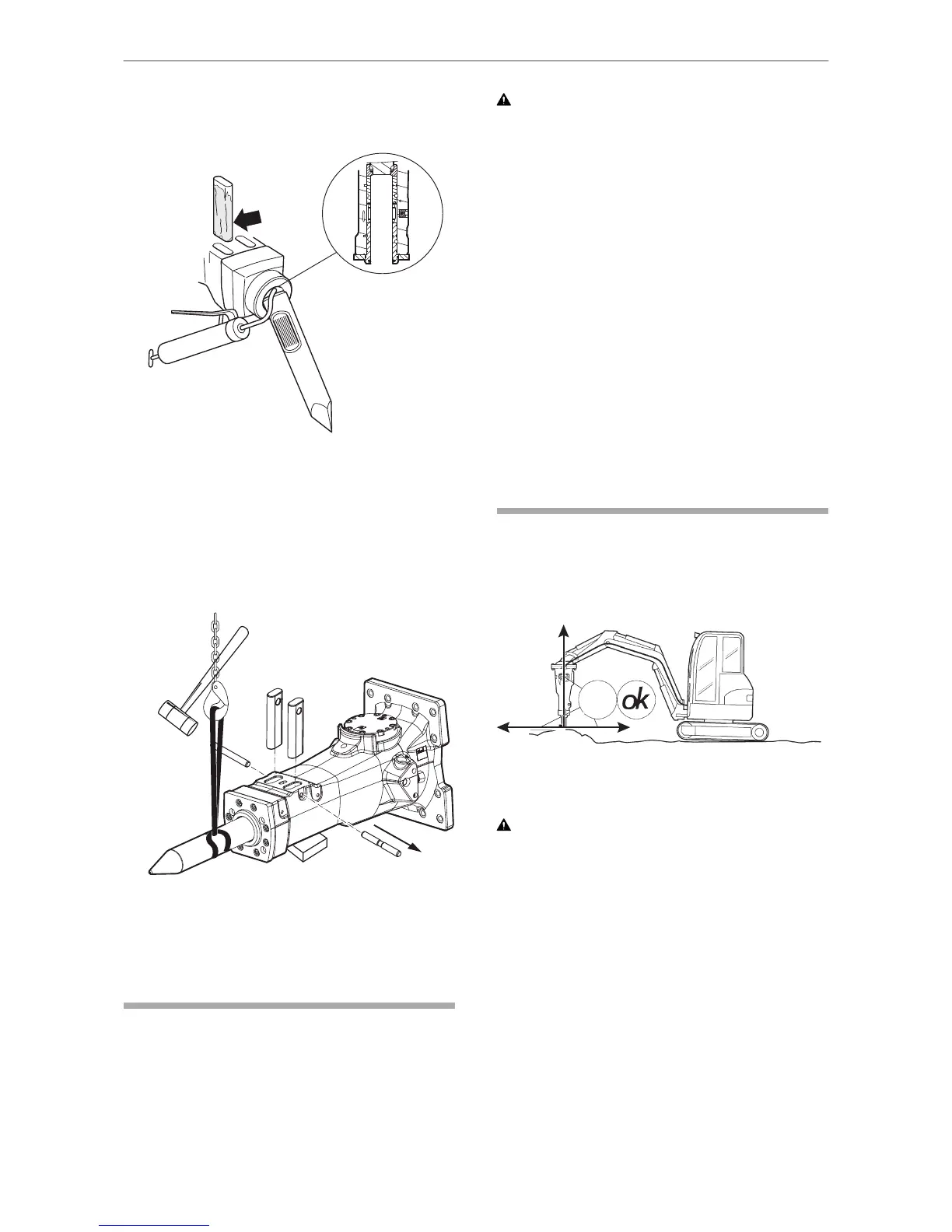

7. Mount the tool retainers, one at the time.

8. Drive in the lock pin until the lock buffer attaches

in the lock pin groove.

Operation

Preparation before breaking

Operating temperatures

The operating temperatures of the hydraulic breaker

are between -20ºC (-4ºF) and + 80ºC (+176ºF).

CAUTION Temperature hazard

The hydraulic breaker and the hydraulic oil system

of the carrier can be damaged if the hydraulic breaker

is used at higher or lower temperatures.

► Only start the hydraulic breaker when the hydraulic

oil has reached the proper operating temperature.

► If the ambient temperature is below – 20ºC (-4ºF),

you must warm up the working tool and the

hydraulic breaker before use.

► If the oil temperature exceeds + 80ºC (+176ºF),

you must not use the hydraulic breaker as the oil

quality becomes inadequate which severely

shortens the life time of seals and O-rings.

Engine rpm

Too high engine rpm only results in increased fuel

consumption and increased oil temperature. Adapt

the engine rpm to the recommended value to give

the correct operating oil flow.

Operating

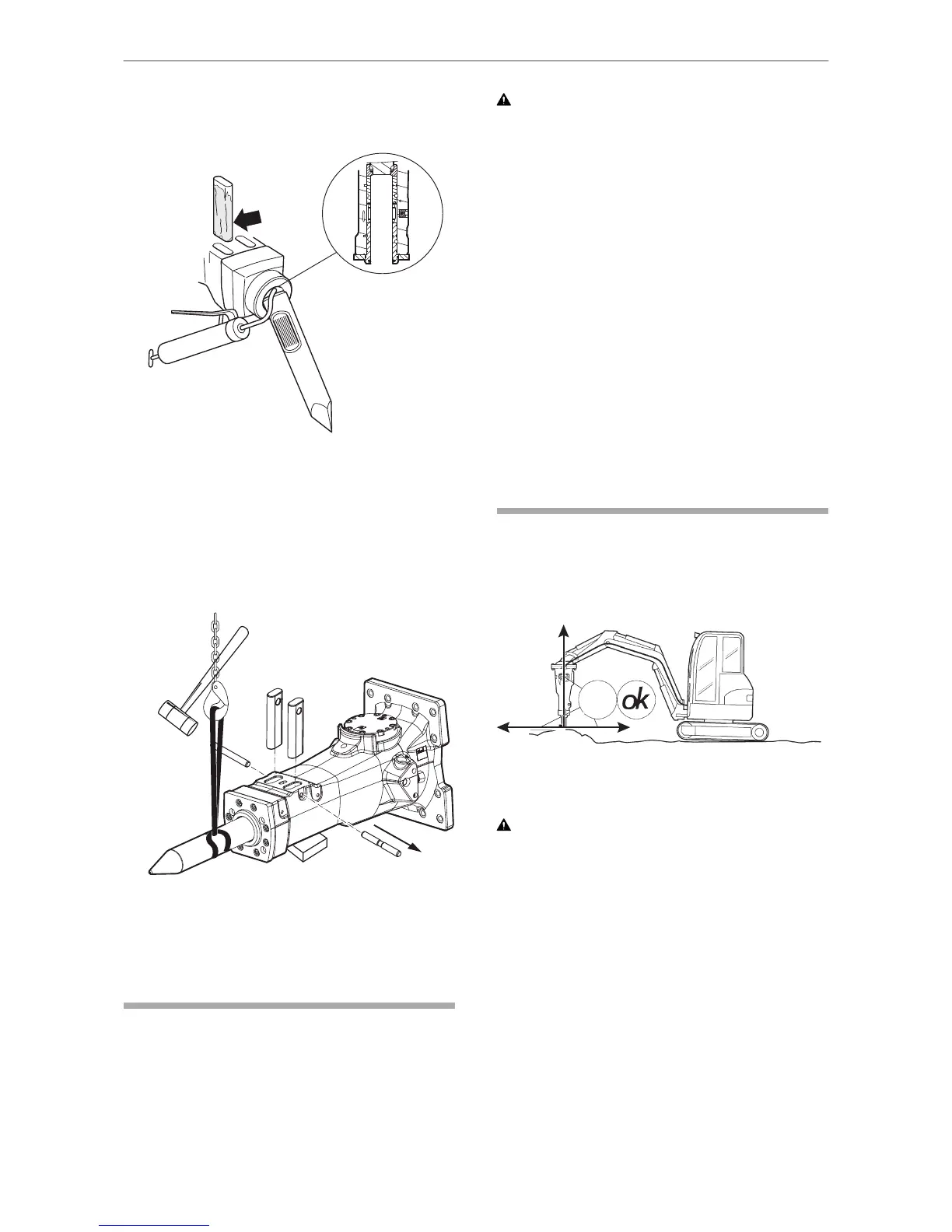

Risk area

Before starting the hydraulic breaker, make sure that

no persons are in the risk area, 20 meters both

horizontally and vertically from the hydraulic breaker.

Breaking

CAUTION Machine and tool hazard

Continuous operation at full extension and/or

retraction can result in damage to the hydraulic

cylinders.

► Always avoid operating the breaker with the

cylinders fully extended or retracted.

► Reposition the carrier and/or boom to avoid fully

extended or retracted cylinders.

► Pay attention and look at what you are doing.

Never start the hydraulic breaker until both carrier

and the hydraulic breaker are in the correct position.

17© 2015 Construction Tools PC AB | No. 9800 1273 01d | 2015-12-30

Original instructions

Safety and operating instructionsSB 702, 1102

Loading...

Loading...