Wear limits

C mm (in.)A mm (in.)

102 (4.0)108 (4.25)SB 702

117 (4.61)123 (4.84)SB 1102

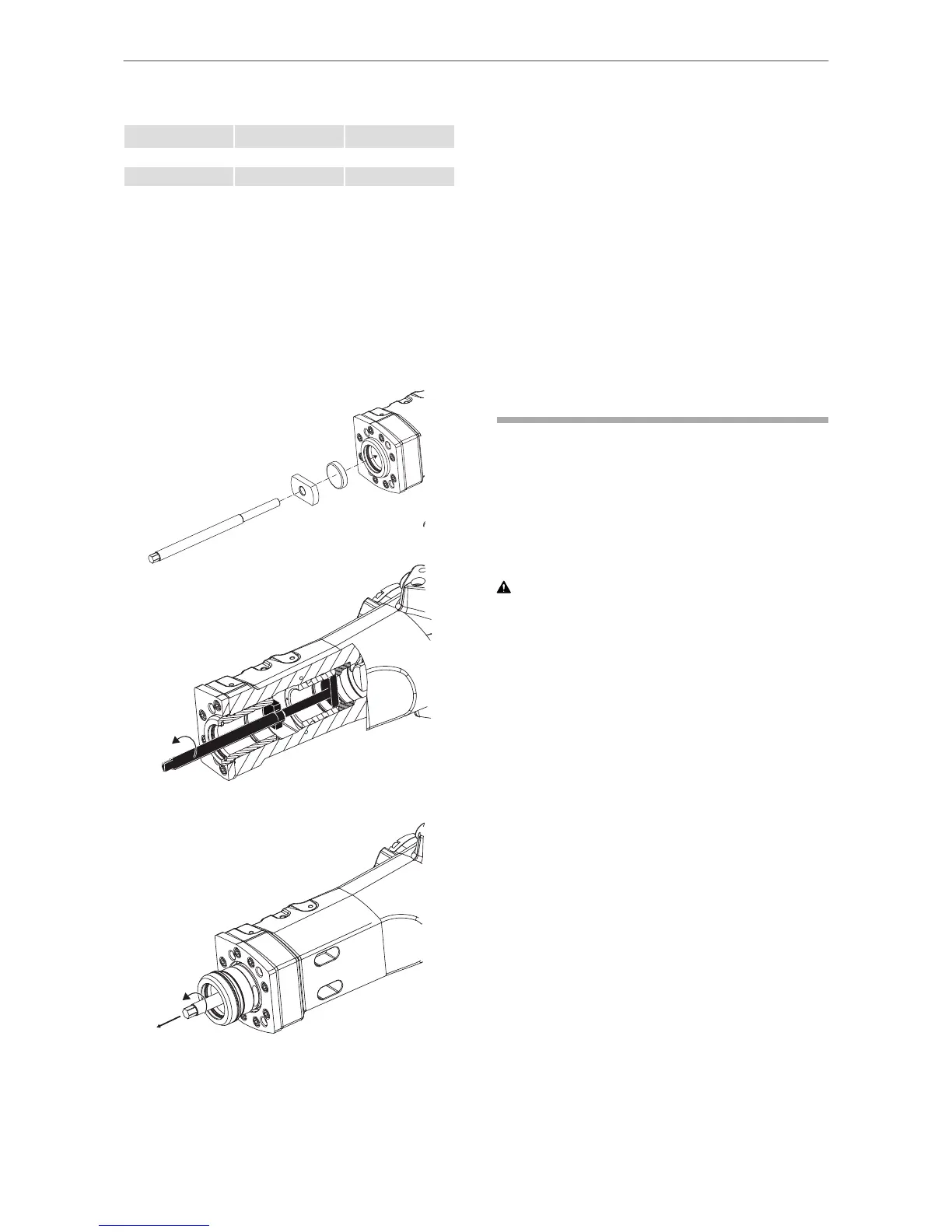

Changing the lower bushing

NOTICE The upper bushing and stop ring must be

replaced in a workshop.

The lower bushing is kept in place by the locking pin.

A new bushing has a slip fit.

1. Remove the spring pin and locking pin.

2. Remove the lower bushing and the scraper ring.

If the lower bushing is stuck, use a puller to

remove it.

3. Check the inside diameter of the upper bushing

using the bushing controller, if necessary change

the upper bushing at a workshop. For ordering

a bushing controller, see the spare parts list.

4. Carefully clean the bore and the lower bushing

seat area.

5. Mount new O-rings on the new lower bushing.

6. Lubricate the new lower bushing and mount it.

Use a plastic sledgehammer to insert the lower

bushing.

7. Mount a new scraper ring.

8. Mount the locking pin. Rotate the lower bushing

until the locking pin finds its position in the lower

bushing.

9. Lock the locking pin by mounting a spring pin

with a sliding hammer.

Every year

Overhauling must be done after one year of

continuous operation. Overhauling must for safety

reasons be performed by authorised personnel at an

authorised workshop.

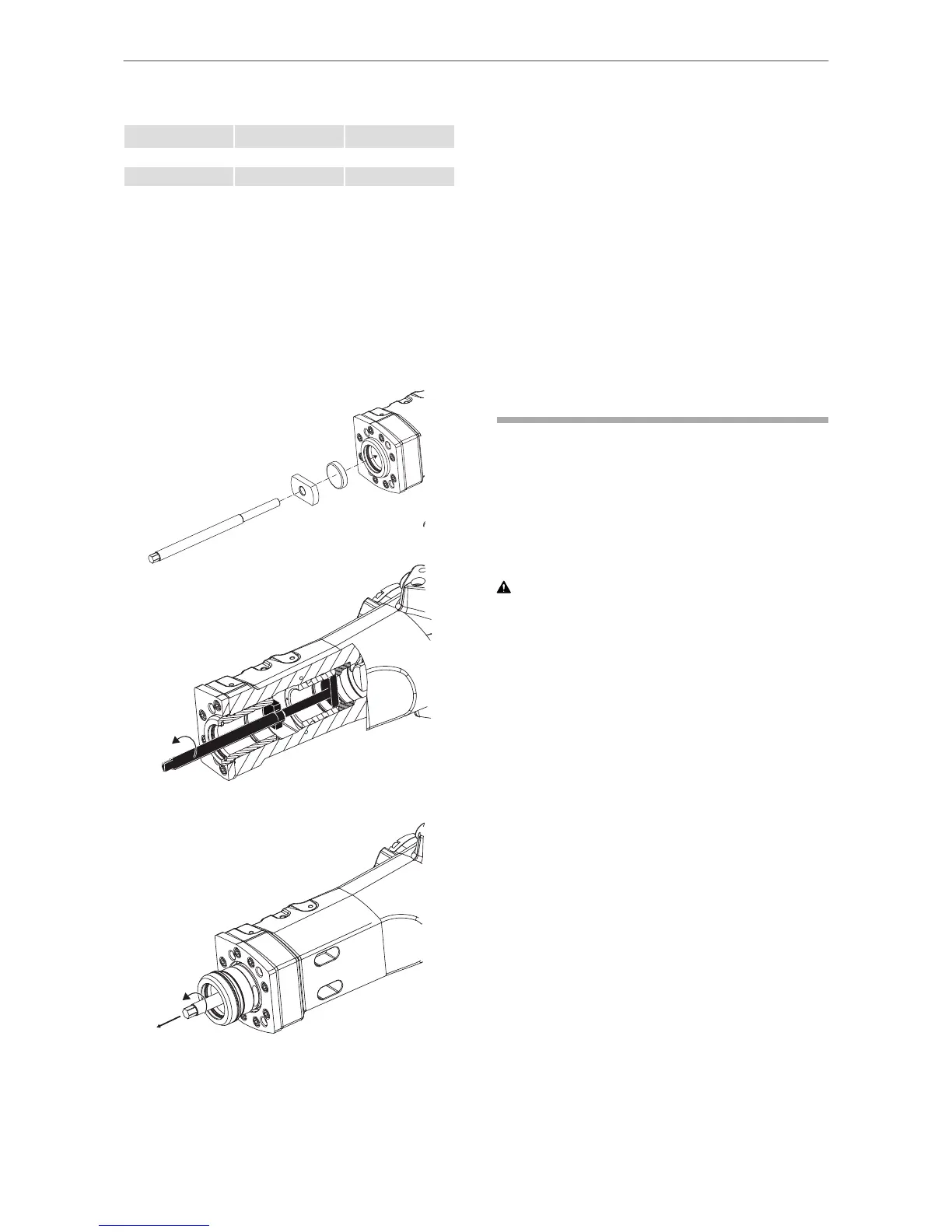

Storage

WARNING Hydraulic breaker / working tool

fall

The hydraulic breaker and the working tool are

heavy. If they topple over or fall down from where

they are stored, injury may be the result.

► Store the hydraulic breaker and the tool so that

they cannot topple over or fall down.

The hydraulic breaker must be stored in an upright

position to avoid its seals being damaged.

If the hydraulic breaker is not used for a long time,

the following points have to be considered to protect

the hydraulic breaker from corrosion:

♦

Remove the hydraulic breaker from the carrier

(see chapter Removing the hydraulic attachment

from the carrier).

♦

Clean the hydraulic breaker carefully (see chapter

Cleaning).

♦

Dismount the working tool (see chapter Working

tool/Removal).

♦

Lubricate the front part of the piston, wear bushing,

and the retainer bars.

♦

Store the hydraulic breaker in a dry place.

Always keep the breaker in an upright position, if

stored for a long time and so that it cannot topple

over.

© 2015 Construction Tools PC AB | No. 9800 1273 01d | 2015-12-30

Original instructions

22

SB 702, 1102Safety and operating instructions

Loading...

Loading...