- 26 -

DURING OPERATION

• Check that the regulating valve is correctly

functioning, i.e. starts decreasing the engine speed

when reaching the working pressure.

• Check on abnormal noise.

• Check the alarm lamps.

AIR OUTLET PRESSURE

The air outlet pressure is set in the factory.

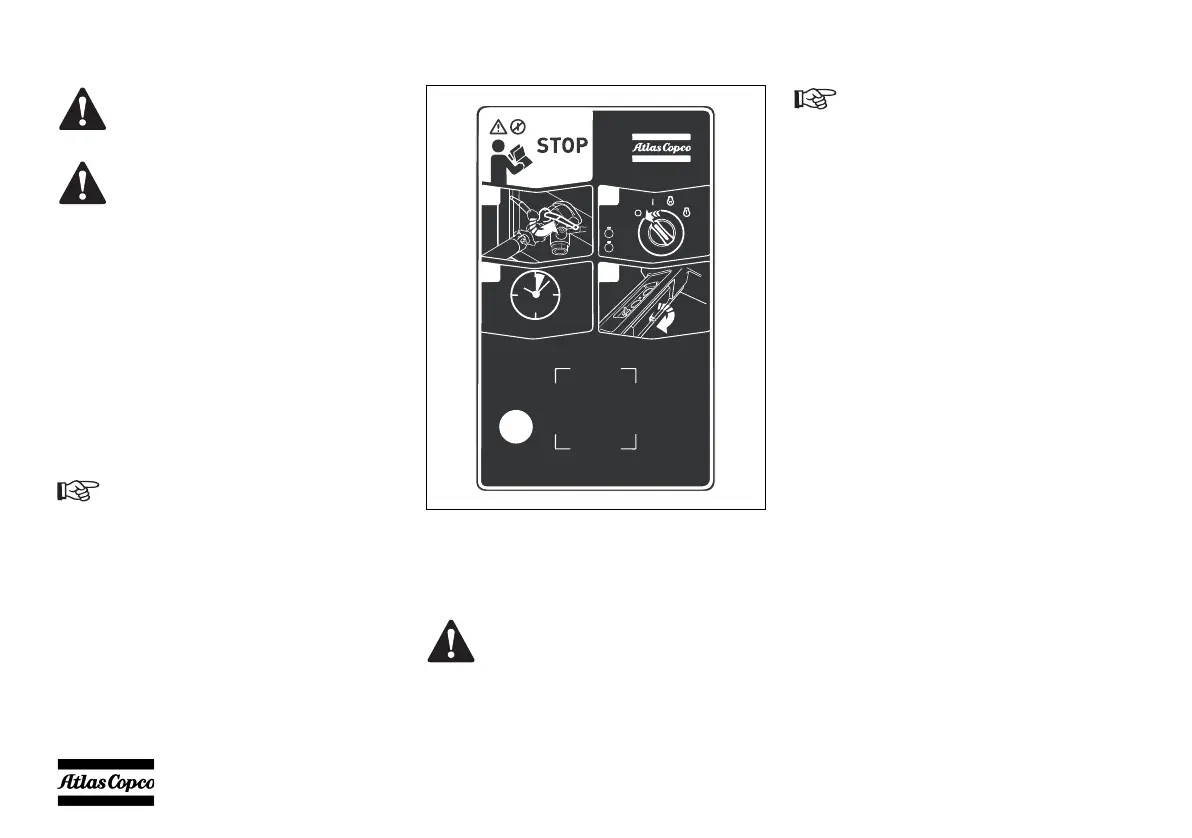

STOPPING PROCEDURE

1. Close the air outlet valves (AOV).

2. Run unloaded for 3 minutes.

3. Turn the start switch S1 counterclockwise (CCW)

to position 0.

4. Open the hood and switch the main switch at the

back of the control panel to “OFF”.

FAULT SITUATIONS AND PROTECTIVE

DEVICES

• A fault involving the engine, either oil pressure

(too low), coolant temperature (too high), will

always and immediately cause the engine to cut

out and the alarm lamp H1 will light up.

• When the air outlet temperature is too high the

alarm lamp H2 will light up. The alarm lamp will

stay on, until the compressor has been restarted

(start switch to position 3), or the contact is

turned off (start switch to position 0; also when,

due to cooling off, the thermocontact has closed

again (= memory function).

When the engine is running, the air

outlet valves (ball valves) must always be

in a fully opened or fully closed position.

The hood must be closed during

operation and may be opened for short

periods only.

Be aware not to touch hot parts when the

hood is open.

Modifying the set point above the

nominal working pressure can affect the

correct working of the unit and result in

failure. Only the Atlas Copco customer

center or an authorized distributor may

work on, or adjust the regulating valve!

Incorrect use/operation of the machine,

including modifying the working

pressure above the nominal pressure,

will void warranty.

Be aware not to touch hot parts when the

hood is open.

?

3 MIN

OFF

NEED

HELP

SCAN

ME

1638 2153 00

1

2

3

4

Do not open the air outlet valve when

machine is shut down. Remaining air

inside the vessel will automatically be

evacuated via a blow down valve!

If pressure is released from the vessel too

quickly, oil will start creating foam. This

foam could reach the oil separator

element resulting in oil carry over.

Failures caused by incorrectly shutting

down the compressor will not be covered

by warranty!

Box_2-2.book Page 26 Friday, October 27, 2017 3:48 PM

Loading...

Loading...