- 36 -

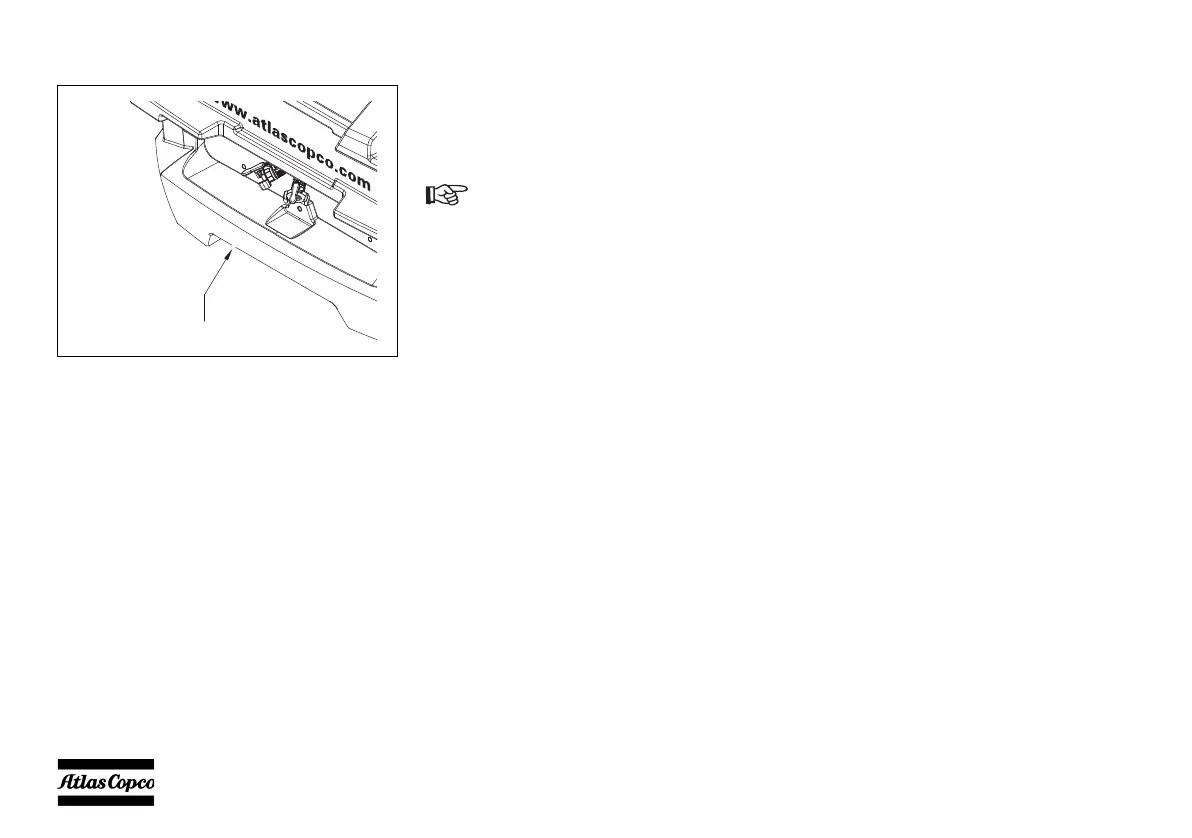

SPILLAGE-FREE FRAME

The compressor is fitted with a leak-proof

undercarriage in order to protect the environment.

Any leaking fluid is collected in case of malfunctions.

This fluid can be removed via a drain (1), normally

secured by caps.

Tighten the cap firmly and check for leakages.

Please observe the locally applicable environmental

regulations when removing the leaked liquid.

STORAGE

Run the compressor regularly, e.g. twice a week, until

warm.

Load and unload the compressor a few times to

operate the unloading and regulating components.

Close the air outlet valves after stopping.

OPTIONS

Multi-approved vessel

Standard the machine comes with a CE approved

vessel. The multi approved vessel includes ASME,

CRN, MOM, AS1210 and ML approval.

Additional fuel filter

When bad fuel quality is a risk, an additional fuel

filter with water separator is recommended.

Safety cartridge

In case of highly polluted / dusty environments a

safety cartridge is recommended. This gives extra

protection in case of a rupture in the filter element.

Toolbox

A toolbox is located inside the bodywork above the

battery and can be easily removed to access the

battery below if required.

Non-return valve

A non-return valve can be installed between vessel

and air outlet valves to prevent air of flowing back to

the vessel when using pressurized equipment.

Cold weather equipment

With cold weather equipment we guarantee starting

down to -20°C.

If the compressor is going to be stored

without running regularly, protective

measures must be taken.

Contact Atlas Copco for correct

measures.

Box_2-2.book Page 36 Friday, October 27, 2017 3:48 PM

Loading...

Loading...