- 32 -

DURING OPERATION

Regularly carry out following checks:

1. That the regulating valve (RV) is correctly

adjusted, i.e. starts decreasing the engine speed

when reaching the preset working pressure in the

receiver.

2. Check the air filter vacuum indicator (VI). If the

yellow piston reaches the red marked service

range, replace the filter element. Reset the

indicator by pushing the reset button.

Fault situations and protective devices:

A fault which occurs with the engine, either oil

pressure (too low), coolant temperature (too high),

will always and immediately cause the engine to cut

out and the alarm lamp H1 will light up.

By doing some simple checks, it can be determined

what it was that caused the engine to fail: low oil

level, clogged-up cooler.

Alarm lamp H2 will light up. The alarm lamp will

remain on, until the compressor has been restarted

(start switch to position 3), or the contact is turned off

(start switch to position 0; also when, due to cooling

off, the thermocontact has closed again (= memory

function).

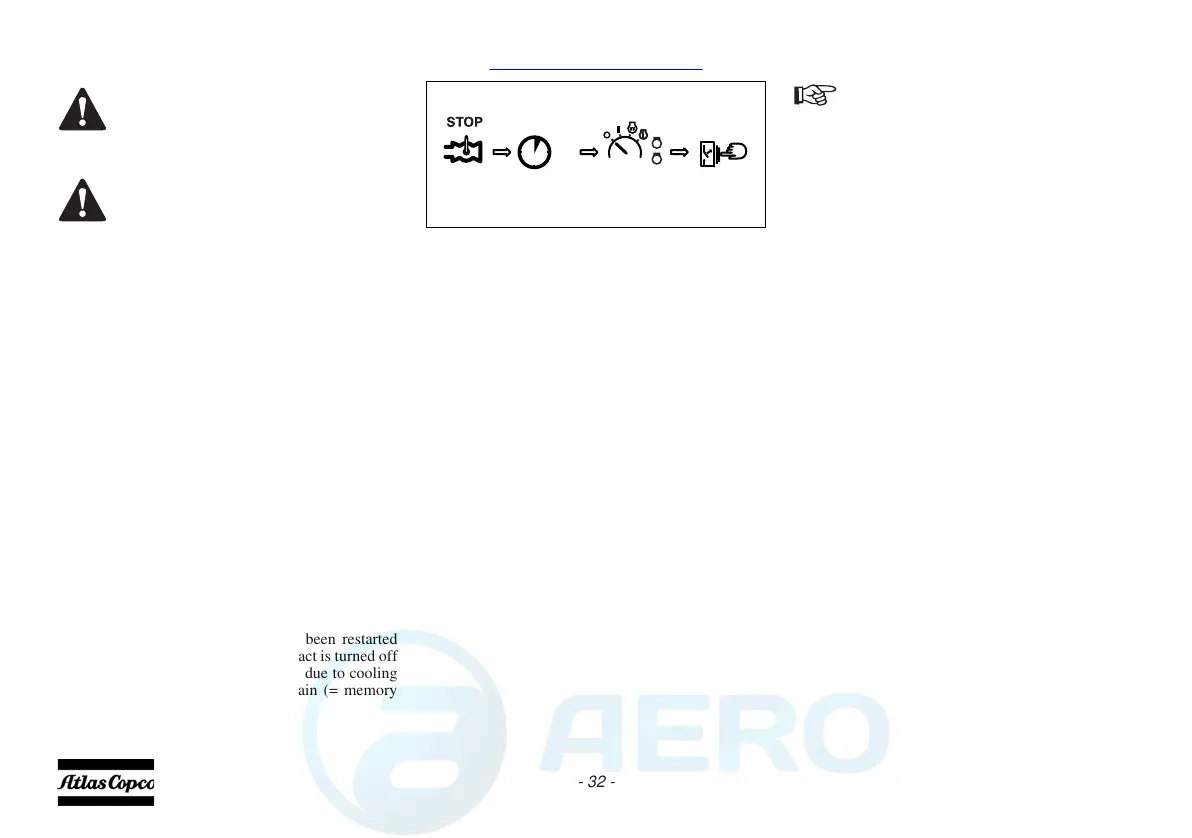

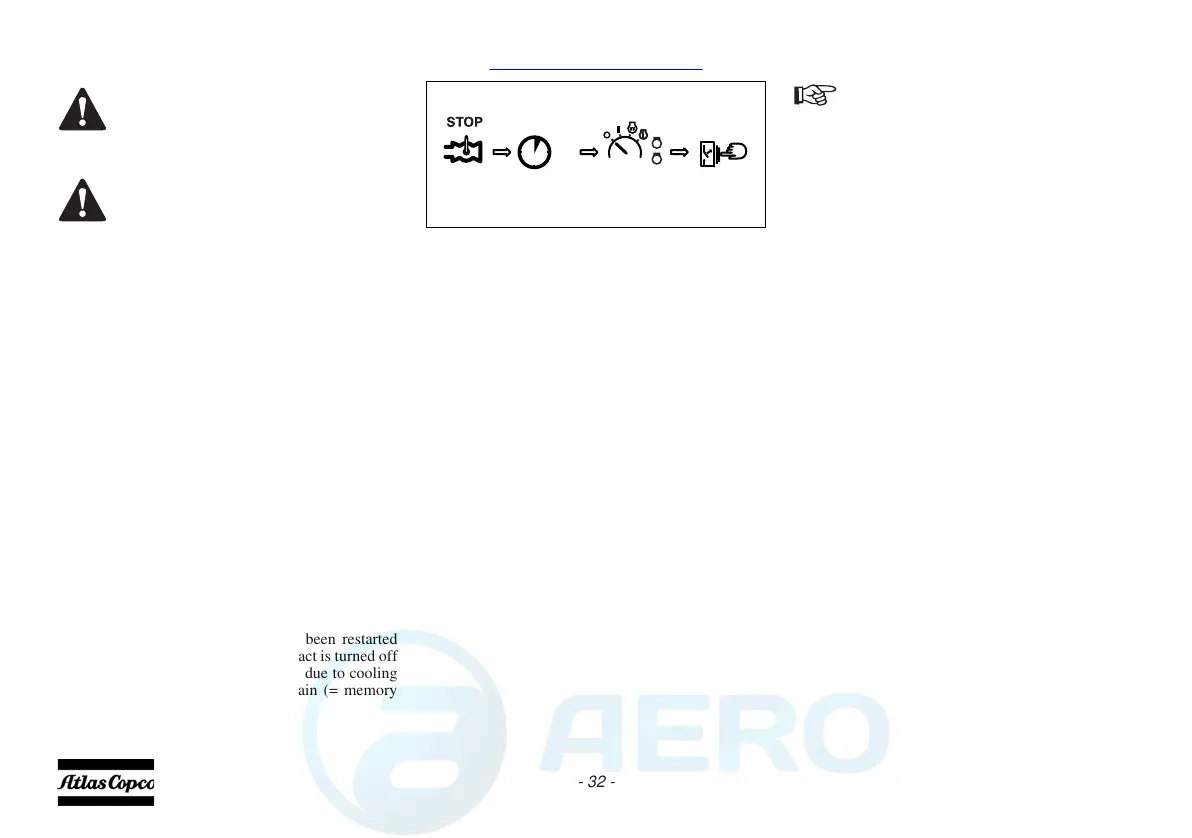

STOPPING PROCEDURE

1. Close the air outlet valves (AOV).

2. Run unloaded for 3 minutes.

3. Turn the start switch S1 counterclockwise (CCW)

to position 0.

4. Push the circuit breaker button (F1) once (open

hood first).

When the engine is running, the air

outlet valves (ball valves) must always be

put in a fully opened or fully closed

position.

The hood must be closed during

operation and may be opened for short

periods only.

Do not open the air outlet valve when

machine is shut down. Remaining air

inside the vessel will be evacuated via a

blow down valve automatically!

If pressure is released from the vessel too

quickly, oil will start creating foam. This

foam could reach the oil separator

element resulting in oil carry over.

Failures caused by not correctly shutting

down the compressor will not be covered

by warranty!

Loading...

Loading...