14 Bend-Tech Dragon A150

Plasma Cutting Guide

Consumables

01

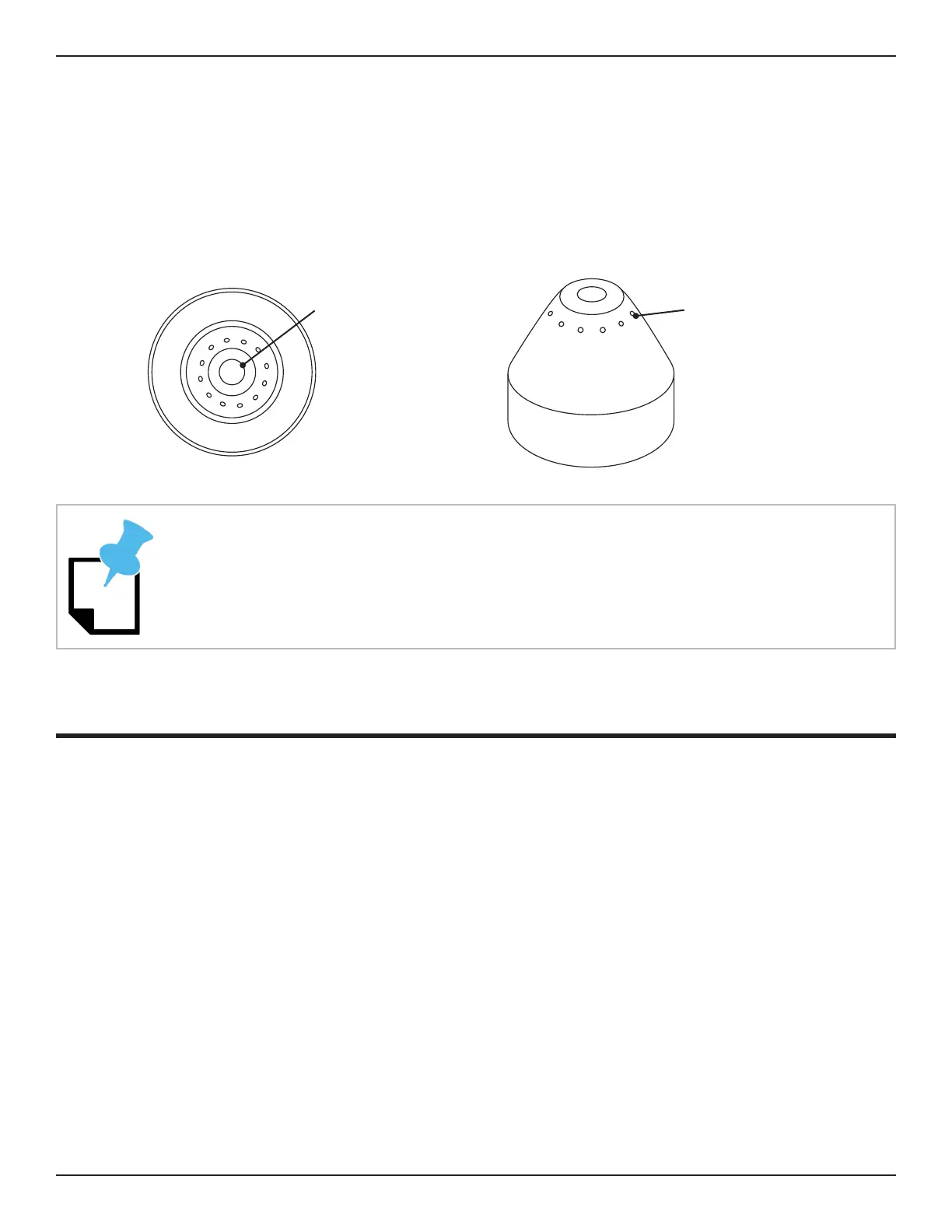

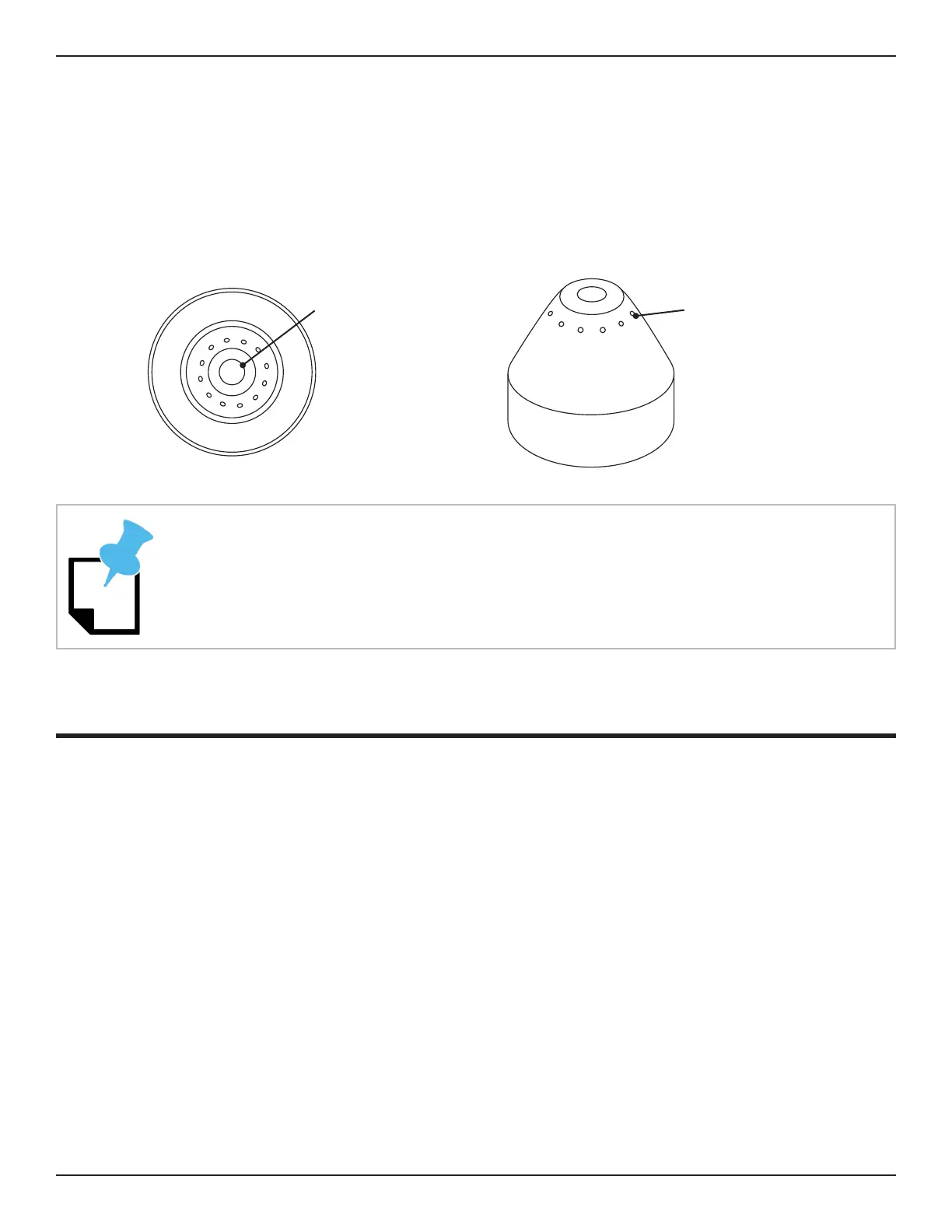

Shield Cap

Inspect the shield cap to ensure all of the holes are clean and not plugged. If the shield cap

cannot vent gas properly it will result in uneven or imprecise cuts. The shield cap will only

need to be replaced if there is evidence of physical damage and/or if the hole is out of round. If

there is spatter on the Shield it may still be usable. However, it may also be an indication that

the Torch is set too close to the material, especially in regard to materials thinner than .25 in.

Signs that Consumables Need Replacing

Signs of a Bad Electrode

• Torch not cutting at required speed

• Green discoloration of the arc

• Excessive dross

•

Signs of a Bad Nozzle

• Kerf too wide

• Operator needs to slow the Torch down because the Torch is not cutting well at desired

speed

• Oblong holes

Do not judge consumables by their color. Staining or discoloration do not necessarily

indicate worn consumables.

Make sure the opening

is not out of round.

Check that the holes are

clean.

Loading...

Loading...