25Bend-Tech Dragon A150

Plasma Cutting Guide

Troubleshooting

03

03

Troubleshooting

Diagnosing Cutting Issues

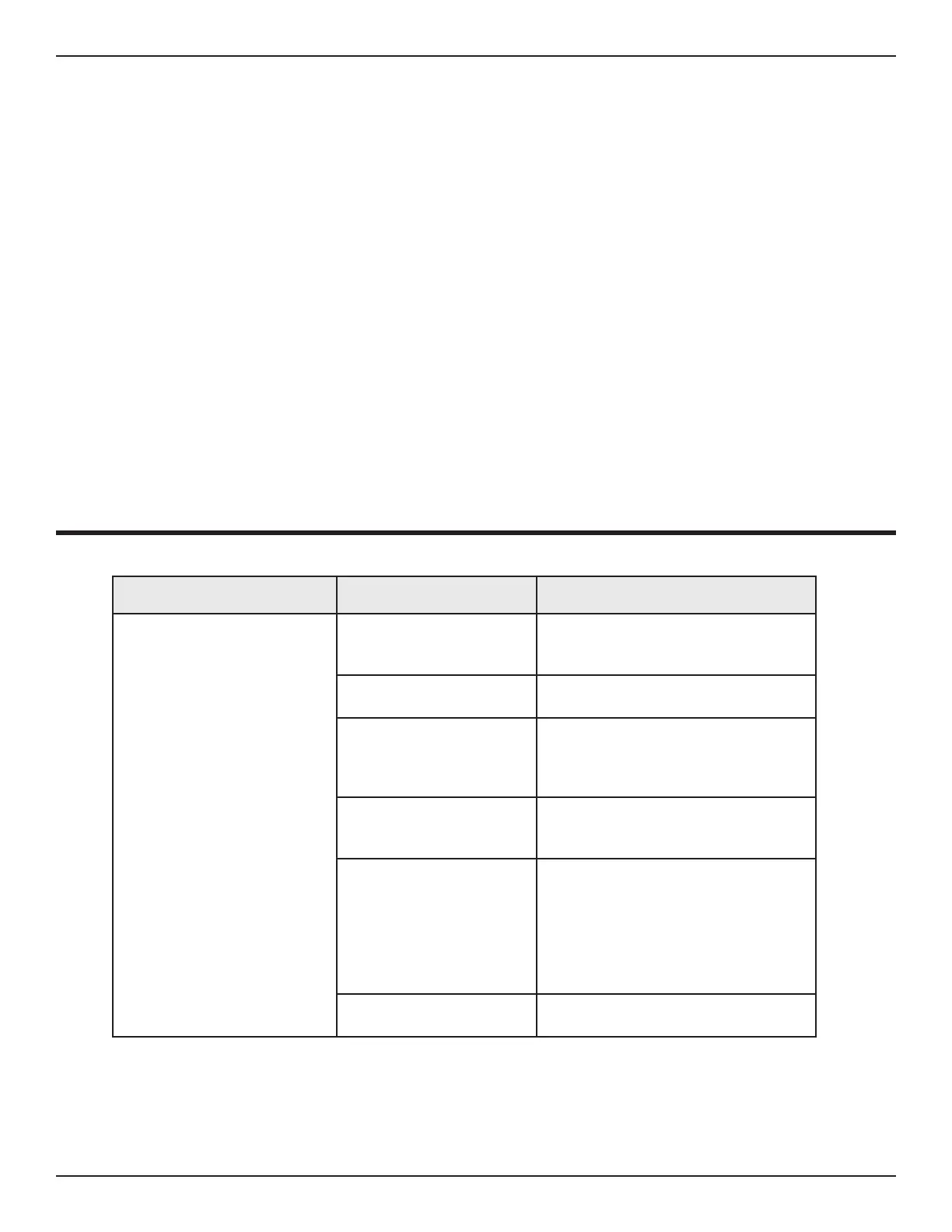

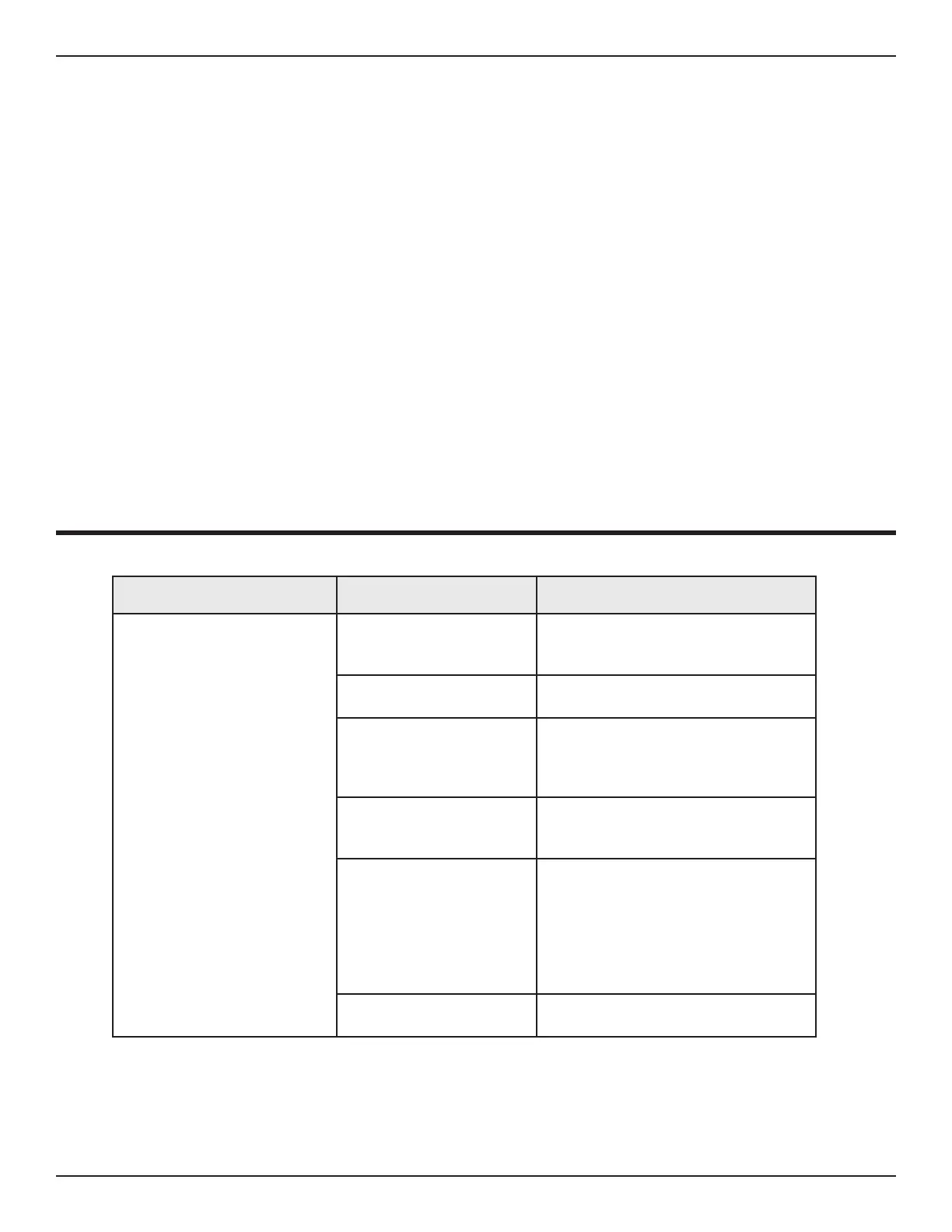

Symptom Cause Corrective Action

Cope at Both Ends of

the Tube are not on the

Same Rotation

Material not properly

secured in the Chuck

Ensure material is tight in Chuck. If

using spacers for the material ensure

the measurements are correct.

Settings in Nesting Project

not correct

Check the part in Edit Flat.

Y Motor Backlash incorrect

Remove Trolley Cover and observe

backlash on Y motor. If incorrect

in Dragon software.

Y motor loose/Drive Gear

loose

Remove Trolley Cover and perform

visual and physical check of Y motor

and Y Motor Drive Gear.

Y motor skipping steps

Check Ethernet connectivity; Check

to ensure Breakout Board is seated

in Motor Drivers properly; Ensure

consistent power to machine. If Y

motor is skipping steps, it is most likely

Y acceleration or RPM is set too high.

Adjust in Dragon software.

X Axis set screw loose

Check X Axis set screw. Apply blue

Loctite 242 and tighten securely.

Loading...

Loading...