26 Bend-Tech Dragon A150

Plasma Cutting Guide

Troubleshooting

03

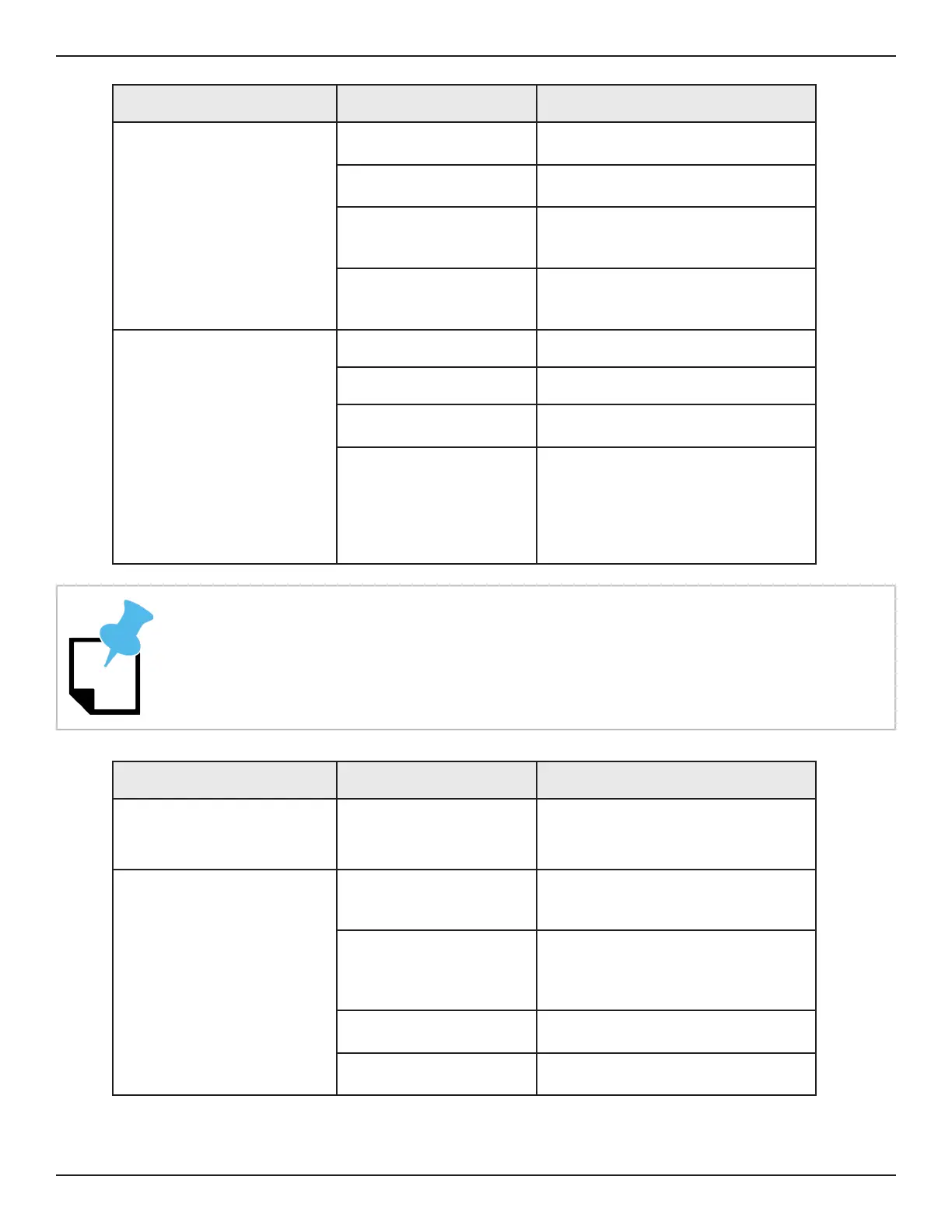

Symptom Cause Corrective Action

Cut Quality Issues

Torch consumables worn

out

Inspect Torch consumables, measure

pit depth of electrode.

Incorrect Torch height

settings

Check settings in software and Torch

height on machine.

Incorrect cutting speed

Ensure cutting speed is correct in

regard to amperage and material

thickness.

Incorrect cutting amperage

Ensure consumables match the

amperage settings on the machine.

Set cut speed appropriately.

Round Holes are Coming

Out Oval

Cutting speed Adjust material feed rate.

Material loose in Chuck Ensure material is secure in Chuck.

Gate too tight or too loose

Ensure material moves freely in Gate

with no play.

Backlash

Perform a Backlash Test in Machine

Library > Mechanical Settings.

Remove the Trolley cover and perform

a visual inspection of backlash.

Ensure all motors are tight. Tighten all

X Axis set screws.

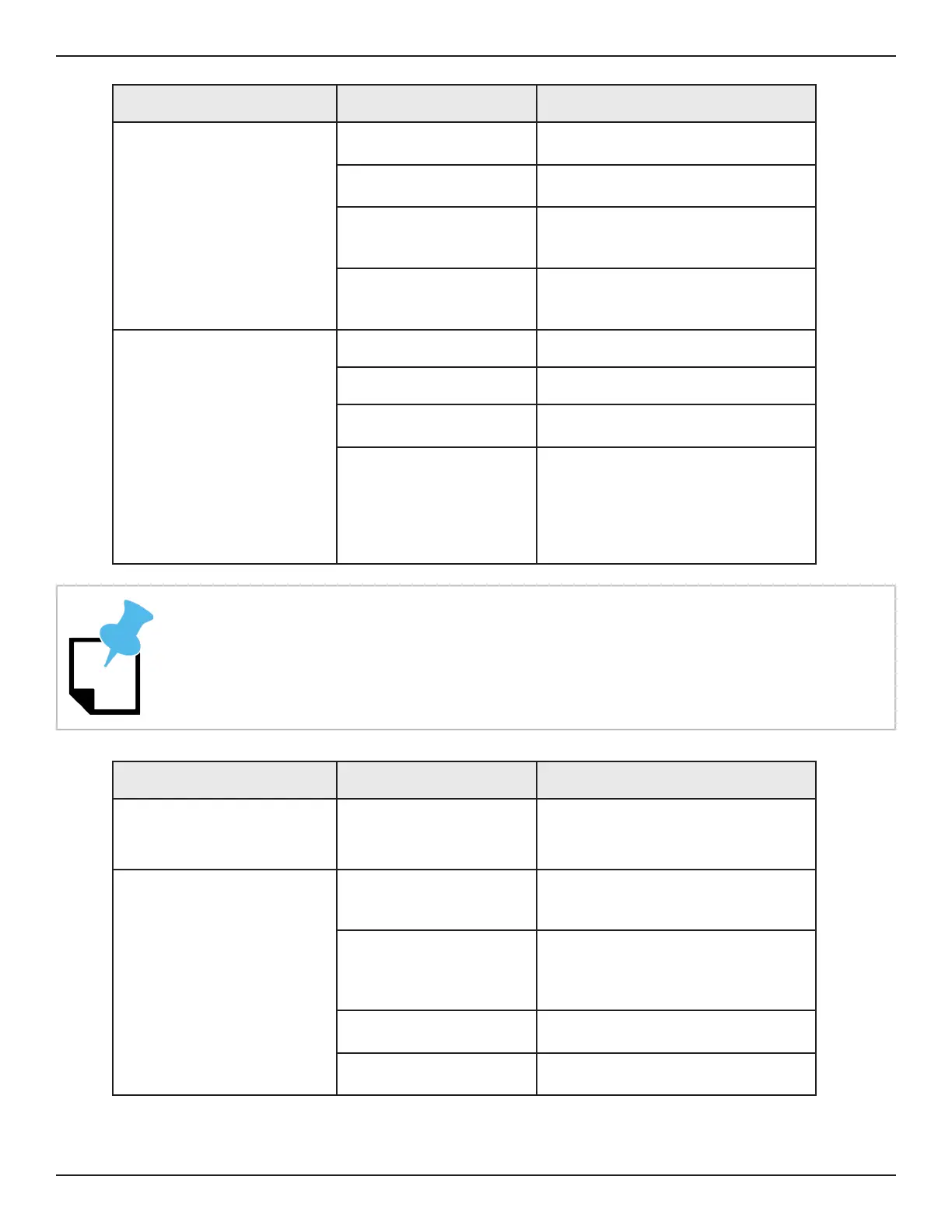

Symptom Cause Corrective Action

Machine Cutting and

then Returning to

Previous Engraving

Order of actions incorrect

in software settings

Change order of actions

Machine Library > Basic > Default

Process Order.

Jagged Cuts

Material feed rate too high

Ensure consumables match the

amperage settings on the machine.

Set cut speed appropriately.

Amperage incorrect

Ensure amperage is set to cutting

charts in this manual. It is possible the

amperage may need to be adjusted by

the Operator to achieve best results.

Gate too tight on material

Ensure material moves freely in Gate

with no play.

X Cable too loose or too

tight.

Check tension on X cable, adjust as

needed.

On thicker material, round holes may appear oval. However, while the hole may

appear oval on the OD of the material, the hole will be round on the ID of the material.

This is part of the normal cutting process of the Dragon A150.

Loading...

Loading...