1 689 975 252 2019-05-15| Robert Bosch GmbH

2 | ACS 511 | en

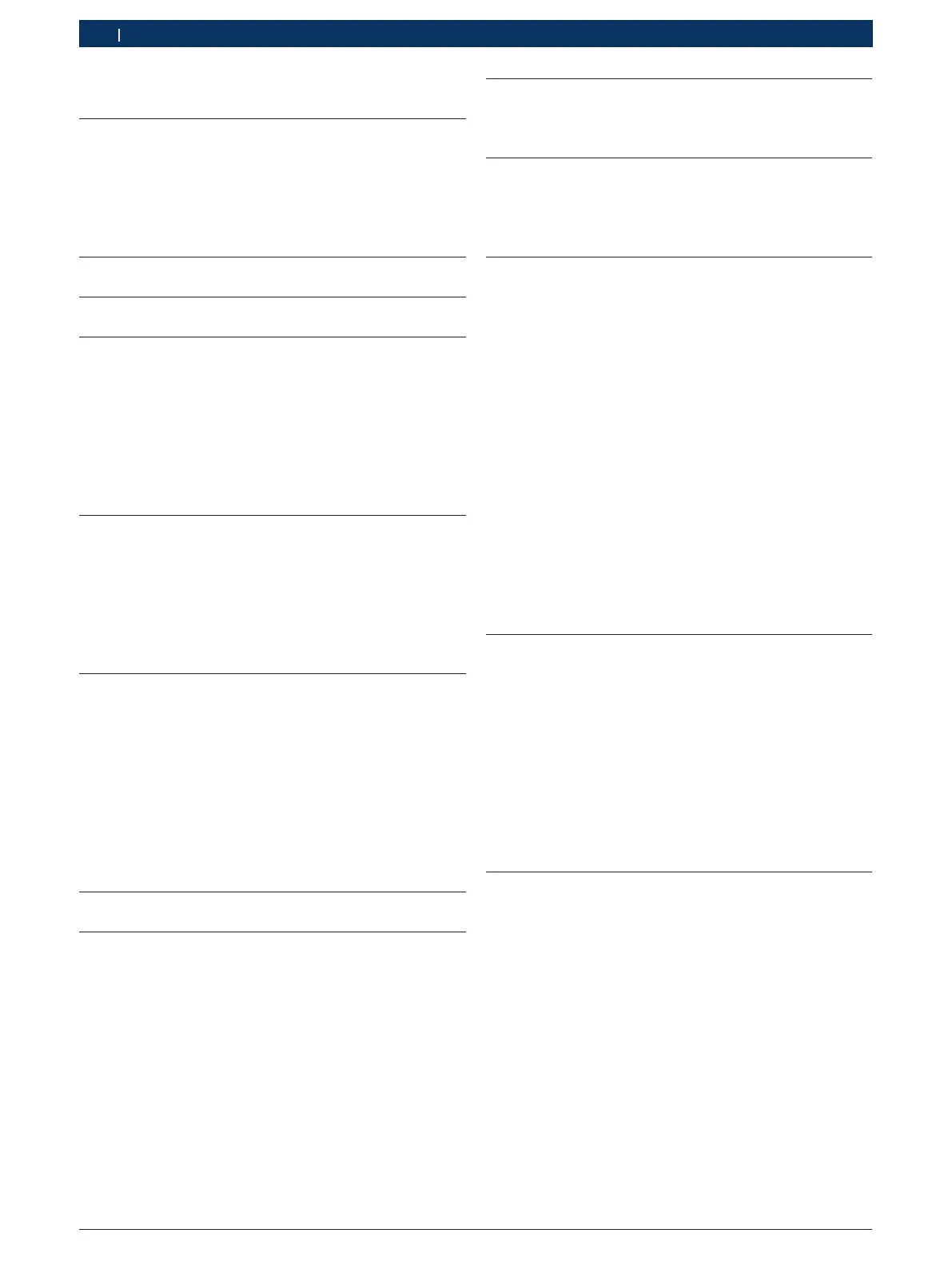

en – Contents

1. Symbols used 3

1.1 In the documentation 3

1.1.1 Warning notices -

Structure and meaning 3

1.1.2 Symbols in this documentation 3

1.2 On the product 3

2. Important information 4

3. Test equipment and auxiliary materials 4

4. Safety regulations 5

4.1 Handling refrigerant R134a 5

4.2 Handling UV dye 5

4.3 Working on the vehicle 5

4.4 Notes on operation 6

4.5 Maintenance work 6

4.6 Safety devices 6

4.7 PED directive 2014/68/EU 6

5. Product description 7

5.1 Description of unit 7

5.1.1 Front view 7

5.1.2 Rear view 7

5.1.3 Display and control panel 8

5.1.4 Selection and function keys 8

5.1.5 Input keys 8

6. Program structure 9

6.1 Calibration and tare 9

6.2 Settings 9

6.3 Repair 9

6.4 Vehicle and customer data 9

6.5 Menu 9

6.6 Manual mode 9

6.7 Automatic mode 9

6.8 Flush (optional) 9

6.9 Enter 9

7. Hydraulics diagram 10

8. Service phases 11

8.1 Recovery 11

8.2 Draining oil into the used oil bottle 13

8.3 Vacuum phase and recycling

(simultaneous) 14

8.3.1 Vacuum phase 14

8.3.2 Recycle 14

8.4 Leak test 16

8.5 Refrigerant preparation 17

8.6 Fresh oil filling 18

8.7 UV contrast medium filling 19

8.8 Filling refrigerant 20

8.9 Separating and returning compressor oil 21

8.10 Non-condensing gases 22

9. Troubleshooting 23

9.1 Service messages 23

9.2 Fault messages 23

10. Emptying the ACS 511 24

10.1 Automatic emptying 24

10.2 Extraction of internal refrigerant circuit with sec-

ond A/C service unit 24

11. TROUBLESHOOTING AND ANALYSIS 25

11.1 Faults during recovery 25

11.1.1 Compressor starts 25

11.1.2 Compressor does not start 25

11.1.3 Fault messages that can occur during

recovery 26

11.1.4 Other fault messages 26

11.2 Faults during the vacuum phase 26

11.2.1 The vacuum pump starts 26

11.2.2 The vacuum pump does not start 26

11.2.3 Fault message that can occur during the

vacuum phase 27

11.3 Faults during refrigerant preparation 27

11.4 Non-condensing gases are not drained 27

11.5 Faults during filling with refrigerant 27

11.5.1 Vehicle air conditioning system cannot be

filled 27

11.5.2 Other fault messages 27

12. Component test and maintenance 28

12.1 Vacuum pump 28

12.2 Pressure sensor P1 28

12.3 Pressure switch P2 28

12.4 Expansion valve 28

12.5 Combo filter 29

12.5.1 Replacement of combo filter 29

12.5.2 Reset filter 29

12.6 Vacuum pump 30

12.6.1 Changing vacuum pump oil 30

12.6.2 Reset of oil change interval 30

13. Calibration 31

13.1 Internal refrigerant cylinder scales 31

13.2 Fresh oil bottle scales 31

13.4 Tara values 32

13.3 Used oil bottle scales 32

13.5 Pressure sensor 33

13.5.1 Checking the adjustment 33

13.5.2 Adjusting the pressure sensor 33