F 002 DG9 918 2017-10-16| Bosch Limited

26 | EPS 610 | Maintenanceen

8. Maintenance

! Work on electrical and hydraulic equipment is only to

be performed by persons with sufficient knowledge

and experience of electrical and hydraulic systems.

8.1 Cleaning

! Do not use any abrasive cleaning agents or rough

cleaning cloths.

¶ Only use soft cleaning cloths and neutral cleaning

agents to clean the EPS 610.

8.2 Spare and wearing parts

Designation Order no.

Hose for calibrating oil supply F 002 81N F07

Suction strainer F 002 81N F75

Filter insert F 002 DG1 9F2

Flexible coupling 1 686 401 026

8.3 Servicing

The EPS 610 requires proper maintenance at regular

intervals. The maintenance intervals are recommended

under the assumption that the EPS 610 is operated for

8 hours at a vehicle service center. The intervals have to

be reduced if the operating time is extended.

¶ Wear safety goggles.

¶ Wear safety gloves.

¶ Wear slip resistant safety shoes.

¶ Wear ear mufflers.

i Do not perform any other maintenance tasks other

than those described in this chapter.

! Quit the voltage supply during the maintenance if

possible.

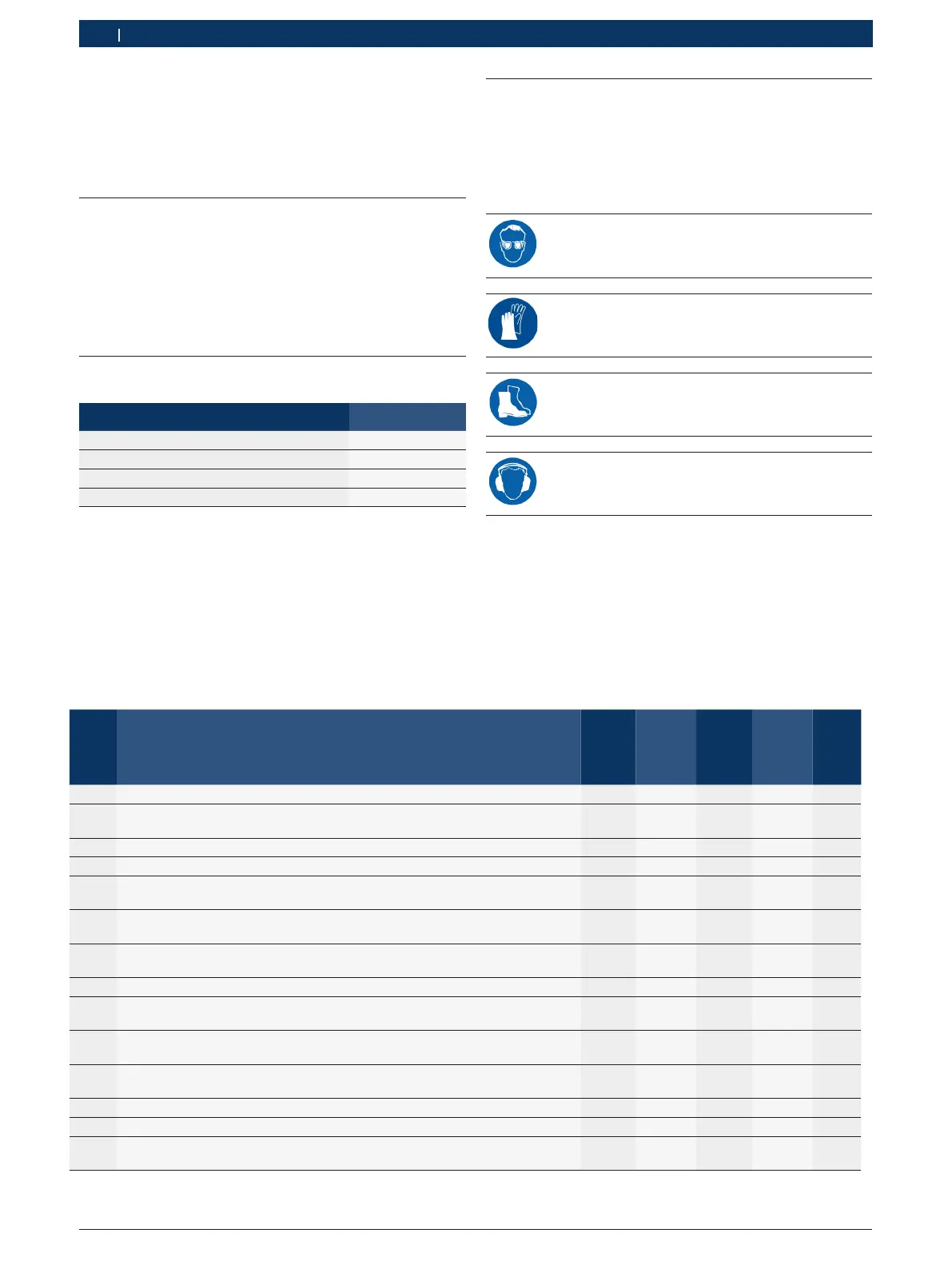

8.3.1 Maintenance intervals

Sl. no.

Maintenance task Daily Weekly

After

testing

200

pumps

During

inspec-

tion

Yearly

8.1 Cleaning of EPS 610 x x

-

Check the measuring glasses visually for any defects. In case of defects, con-

tact customer service to order spare measuring glasses.

x x

8.3.2 Drain the used test oil from the top tray x x

8.3.3 Cleaning of strainer in MGT x x

- Check the nozzle opening pressure pursuant to the regulations. If required,

adjust the pressure.

x x

- Interchange the nozzle holders and pressure lines and compare the flow

rates. The flow rates must be equal.

x x

- Check if the sealing cones and bores of the pressure lines are perfectly func-

tional. Else, replace with new pressure lines.

x x

- Contact customer service to check pressure gauges. x x

- Contact customer service to check accuracy of the temperature unit, mea-

suring and control devices.

x x

8.3.4 Change the test oil in test oil tank. Check for water leakage from the heat ex-

changer into the tank before refilling oil.

x x

8.3.5 Clean and rinse the test oil tank and suction filter. If the suction strainer is

contaminated even after rinsing, contact customer service.

x x

8.3.6 Check the drive coupling. x x

8.3.7 Clean the suction strainer in test oil tank x x

- Tightening torque for fixtures and pumps: Check and tighten if required. Re-

fer chapter 10.3 for information on torque values.

x x

Tab. 5: Maintenance intervals

Loading...

Loading...