6720866940 (2017/11) US SSB

24 | Maintenance schedule & procedures

8 Maintenance schedule & procedures

To maintain proper functionality, operation and efciency it is required

to perform the specic maintenance operations at the specied regular

intervals.

Before carrying out any maintenance operation turn off the

boiler and close the gas supply using the manual ball valve

Time interval Maintenance

Annually

Verify the cleanliness of the area around the

boiler

Annually Check the pressure of the hydraulic system

Annually

Check vent piping and verify if leaks are

present

Annually Check air piping and verify if leaks are present

Annually Check relief valve

Monthly (follow local,

state, federal or local

authority having

jurisdiction guidelines)

Verify the condensate discharge system

Every two months Test low water cut off

Every two months Verify the reset button of low water cut off

Every six months Check all piping (gas and water) for leaks

End of heating season Shut off the boiler

Tab. 10 User maintenance/inspection schedule

Time interval Maintenance

Annually * Combustion test

Annually *

Verify condition of ue and air system

(including Venturi and fan)

Annually * Check ignition electrode

Annually *

Cleaning the combustion chamber (including

the burner tube)

Annually * Clean condensate discharge

Annually *

Safety block check, modulation range check,

gas valve closing after burner stop

Annually * Check control parameters

Annually * Check for gas piping leak

Annually * Check wiring and connection

Annually * Verify startup

Annually * Verify the ame

Annually * Check relief valve

Annually * Inspect the burner gasket

(*) Annually or every 2000 hours. Which occurs rst.

Tab. 11 Licensed contractor / gas tter maintenance / inspection schedule

8.1 Gas Leak Inspection

Inspect all gas piping for leaks.

WARNING: To guarantee no leaks are present utilize a

soap-water mixture or gas detector. Do not use any method

which could result in an explosion.

8.2 Flue / Combustion air piping inspection

Clear vent system of any obstructions, corrosion, water stains, rust.

Verify the connection between the single components. Verify the outside

terminations are clear. Clean the screens and the louvers if there is any

debris.

8.3 Checking for Wiring and connections

Check that all wiring is securely fastened and in good condition without

any cracking or alteration of insulation or presence of corrosion in metallic

connection.

8.4 Burner Head Cleaning

To clean the burner head it is enough to brush the combustion surface

with a paint brush or other soft bristle brush.

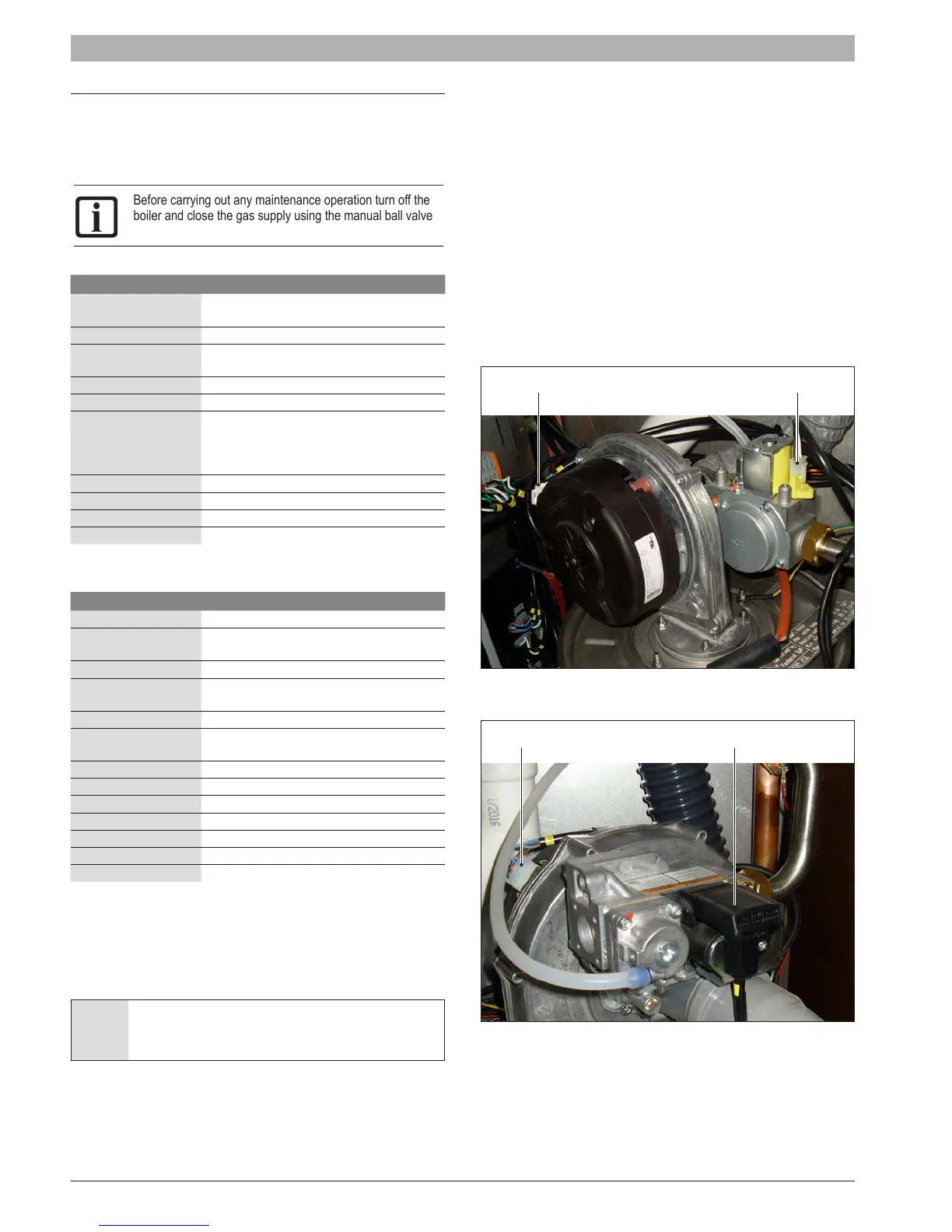

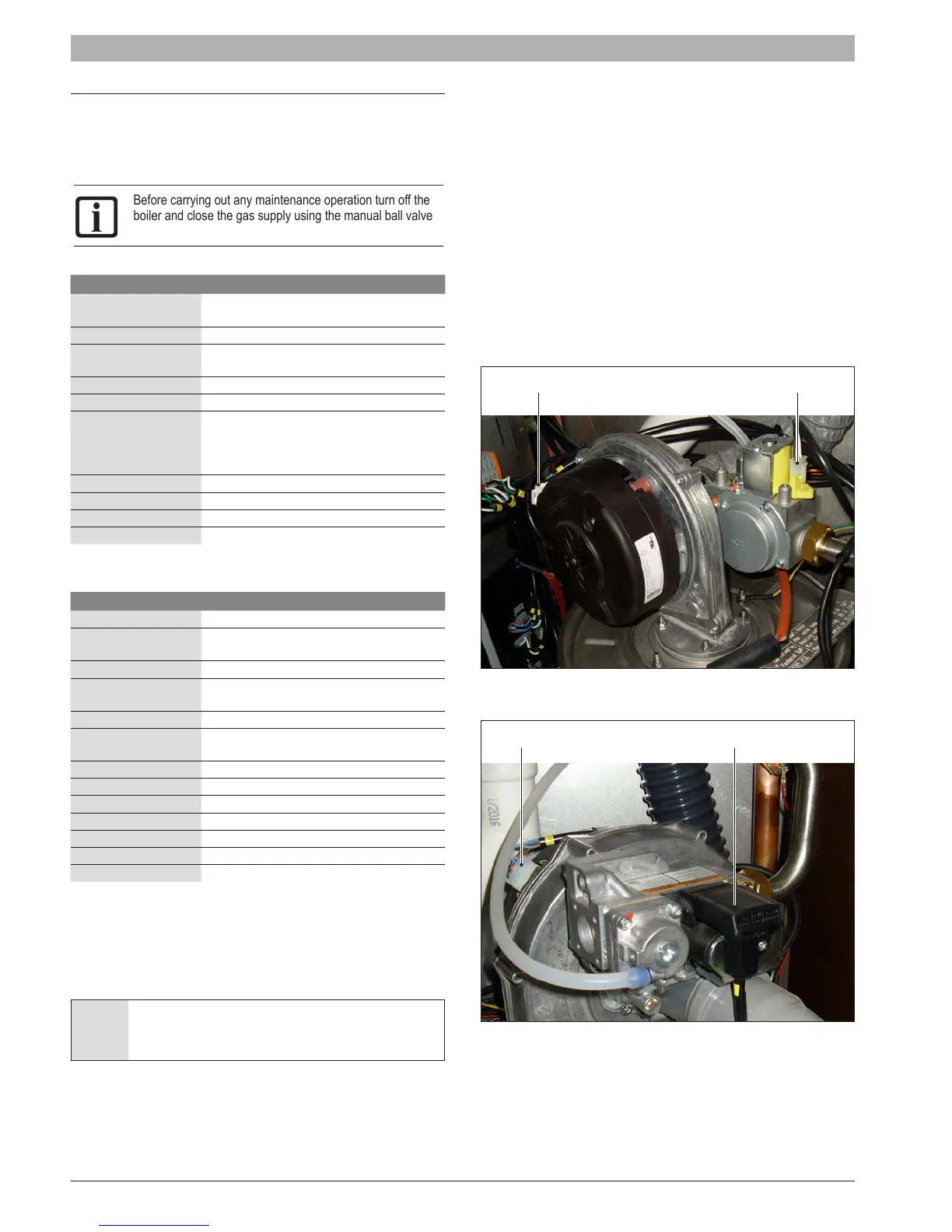

[1] Disconnect the boiler from electrical supply. Disconnect the electrical

connectors from fan and gas valve as shown below;

Fig. 61 Connectors SSB85 - SSB120

Fig. 62 Connectors SSB160

Loading...

Loading...