5

2.3 Process Gas

The R 5 series pumps are designed to pump air and are

not intended for use when water vapor is being

pumped. In some applications, when the quantity of the

water vapor is moderate, R 5 pumps have been used

with good results. On these occasions, the pump is run

until it is up to operating temperature before it is allowed

to pump the process gas. The pump is also operated

for a period of time off process and on air (to clear it of

process gas) before it is shut down. This operating

technique prevents the vapor from condensing in the

pump. Before attempting to pump a gas laden with

water vapor, contact Busch Engineering for advice.

2.4 Stopping Pump

To stop the pump, turn off the power. The pump has a

built-in, anti-suck-back valve (Ref. 251 thru 255) to pre-

vent the pump from rotating backwards when it is shut

off.

Install an automatic operated valve (such as a check

valve) in front of the pump, if more than one pump is

pumping on the same line or if there is a sufficient vol-

ume of vacuum in the system to cause the pump oil to

be drawn into the piping when that pump is shut down.

All R 5 Series pumps are vented internally to atmos-

pheric pressure through venting holes that are next to

the exhaust valve assembly.

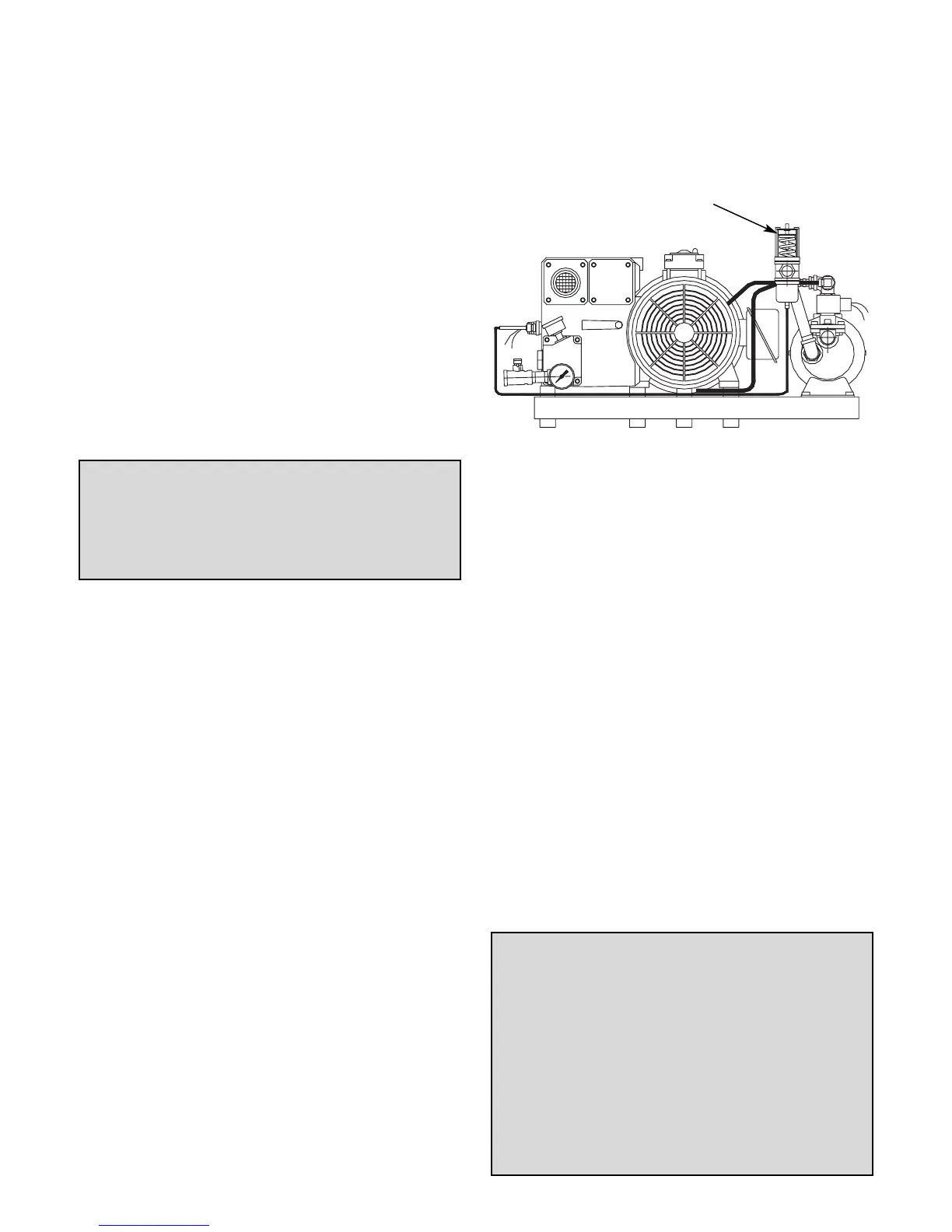

2.5 Water-Cooled Pumps (optional)

Water-cooled pumps are cooled by circulating the oil

through a shell-and-tube type heat exchanger. The cir-

culation of the pump oil through the shell is created by

vacuum in the pump, but the circulation of the cooling

water through the tubes is thermostatically controlled.

The flow rate of the cooling water is controlled by a ther-

mostatically activated valve (see Fig. 2) that senses,

through a capillary bulb mounted in the exhaust box,

the pump's oil temperature as it is discharged from the

compression chamber. The valve will open at its set

point and close at approximately 3°F to 5°F below the

set point. The valve set point is adjustable as follows:

(a) Rotate the valve adjustment screw counterclock-

wise to cause the valve to open at a higher tempera-

ture. This makes the pump run hotter.

(b) Rotate the valve adjustment screw clockwise to

make the valve open at a lower temperature. This

makes the pump run cooler.

The thermostatic valve can be manually opened by

inserting a screwdriver under each side of the spring

guide and prying the spring and guide upward away

from the valve body.

The water cooling option can be used to cool pumps

operating in high ambient temperatures, or it can be

used to maintain a pump at elevated temperatures to

prevent condensation inside the pump in wet applica-

tions. Contact Busch Engineering in for details.

2.6 Oxygen Service Pumps

Oxygen service pumps must be used in oxygen

enriched applications that are defined as any applica-

tion which has a process gas that is 25% or more oxy-

gen. If this pump is contaminated by organic com-

pounds, do not attempt to use it on oxygen service until

it has been decontaminated.

These pumps have been manufactured, solvent

washed (to remove organic contaminants) and assem-

bled according to the latest technical standards and

safety regulations. If this pump is not installed properly

or not used as directed, a dangerous situation or dam-

age might occur. It is mandatory that these operating

instructions be read and understood prior to vacuum

pump installation and start-up!

CAUTION: Do not use the anti-suck-back

valve as a system check valve for your vac-

uum system. Do not depend on the anti-

suck-back valve to prevent pump oil from

migrating through the inlet into the system

when the pump is shut down.

Fig. 2 - Water-cooled Pump

Thermostatic

valve

WARNING: This pump is filled with a special

operating fluid. Do not use any other type

of fluid, oil and/or grease. Use one of the

following:

• Fomblin LC 250

• Tyreno Fluid 12/25V (perfluorinated polyether)

• KRYTOX ® Vacuum pump fluid by Du Pont

Company

If you have any questions, please phone our

Customer Service Department for more information.

Loading...

Loading...