5

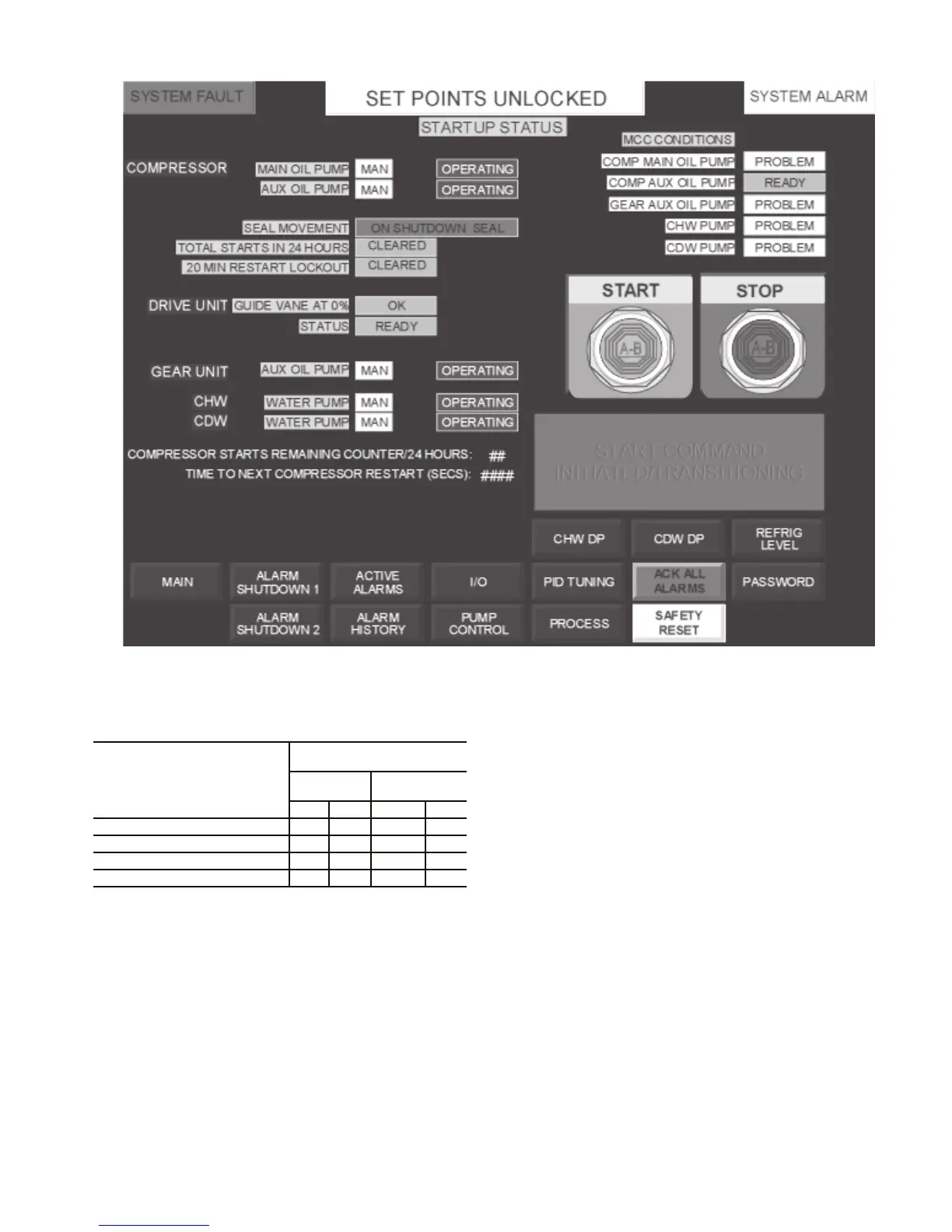

Table 2 — Pumpout System Ratings

Charge Machine with Water — When the machine

has been proved leak tight and dry, it may be filled with water,

brine or other process fluid as the case may be. Vent all lines

and check for leaks.

It is advisable to install indicators on the coupling halves be-

tween the compressor and drive or gear to check for alignment

drift while charging with water and refrigerant. The weight of

these materials will always cause a shift in the position of the

machine components. Before and after indicator readings will

give a good clue to the direction final alignment should take.

Charge Machine with Oil — The 17DA chiller has an

integral lubrication system mounted on a common base with

the compressor. A parallel auxiliary oil pump system may also

be furnished. Charge the oil system with 35 gallons (132.5 L)

of oil, Carrier P/N PP23BZ106.

Refrigerant R-134a requires the use of polyolester oil. Poly-

olester oils have a different molecular structure proprietary to

each manufacturer and have property differences that may or

may not make them suitable for operation in the 17DA chiller.

Carrier supplied oil has been laboratory tested by Carrier and

has been field tested in the 17DA chiller.

Ensure that there is adequate lubrication prior to the opera-

tion of all drive line components. Check the gear and drive

manufacturer’s instructions for proper initial lubrication

procedure.

Oil pressure from the main pump is set to maintain a pres-

sure 35 psi (241 kPa) greater than the refrigerant pressure be-

hind the shaft seal. If the oil pressure differential across the seal

falls below 23 psid (158 kPa), the auxiliary oil pump will start.

Final Pre-Operation Alignment Check — Prior

to operating the compressor and speed increasing gear (if

used), coupling alignment and separation must be checked.

1. Ensure that coupling alignment is within coupling manu-

facturer's specified tolerances.

2. Refer to the coupling vendor’s drawing for hub separa-

tion tolerances.

3. When checking hub separation, electric motor shaft must

be in center position of shaft float or in magnetic center as

specified by the motor manufacturer.

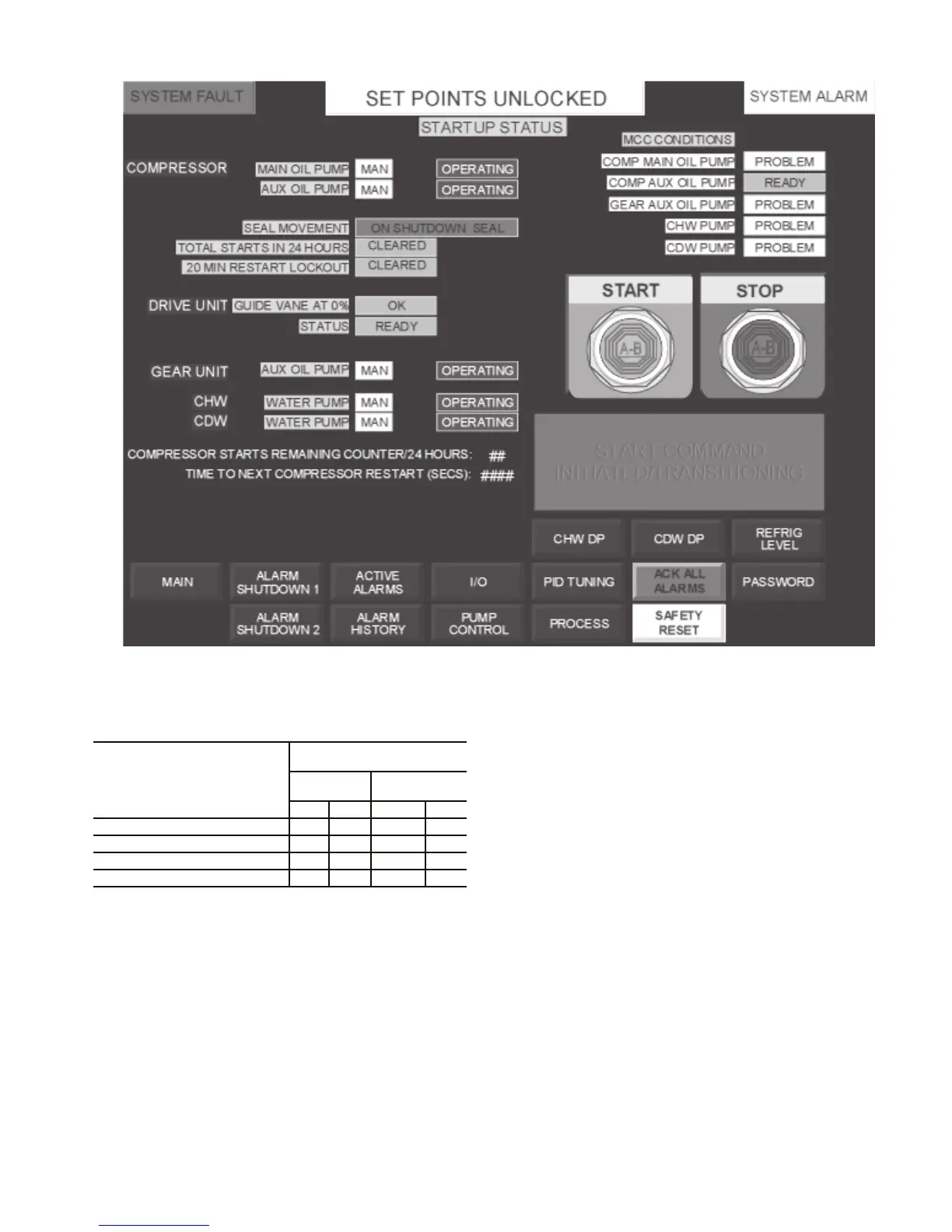

Fig. 1 — Typical PLC Screen on Control Panel

a17-578

PUMPOUT

SYSTEM

SETTING

SATURATED CONDITIONS

(R-134a)

Pressure

Maximum

Temperature

psig kPa F C

Normal Condensing Pressure 146 1007 110 43

Low-Pressure Cutout 31.5 217 36 2

High-Pressure Cutout 175 1207 121 49

Relief Valve 185 1276 125 52

Loading...

Loading...