7

The proportional band can be adjusted on the PLC to sta-

bilize the level if necessary.

3. Start the compressor. Observe the machine's operation for

15 to 20 minutes before increasing the load. During this

period, make the following checks and adjustments:

a. Check oil pressure.

b. Adjust water flow thru oil cooler so that bearing

temperatures stay between 150 and 170 F (65 and

77 C) approximately.

c. Watch bearing temperatures carefully. This is the

first time that the machine has been run under

refrigeration load. Bearing temperatures may level

off at some temperature slightly higher than 170 F

(77 C) listed above. This may be the normal stable

condition for this bearing. High thrust bearing tem-

perature will shut the machine down at 180 F

(82 C).

d. Watch the discharge temperature and if the temper-

ature climbs past 150 F (65.5 C), open the guide

vanes in small steps of 5% or less until the dis-

charge temperature starts to decrease.

4. Slowly open the guide vanes, by manual control, thus in-

creasing the load. Do not exceed the current rating of the

electric motor. Watch for other signs of overloading a tur-

bine or engine drive.

5. Add liquid refrigerant, trimming the charge off at the

point where the machine reaches design operating tem-

perature and pressure conditions.

6. Shut the machine off. When the refrigerant level settles

down, mark this optimum level on the sight glass. Main-

tain this shutdown level.

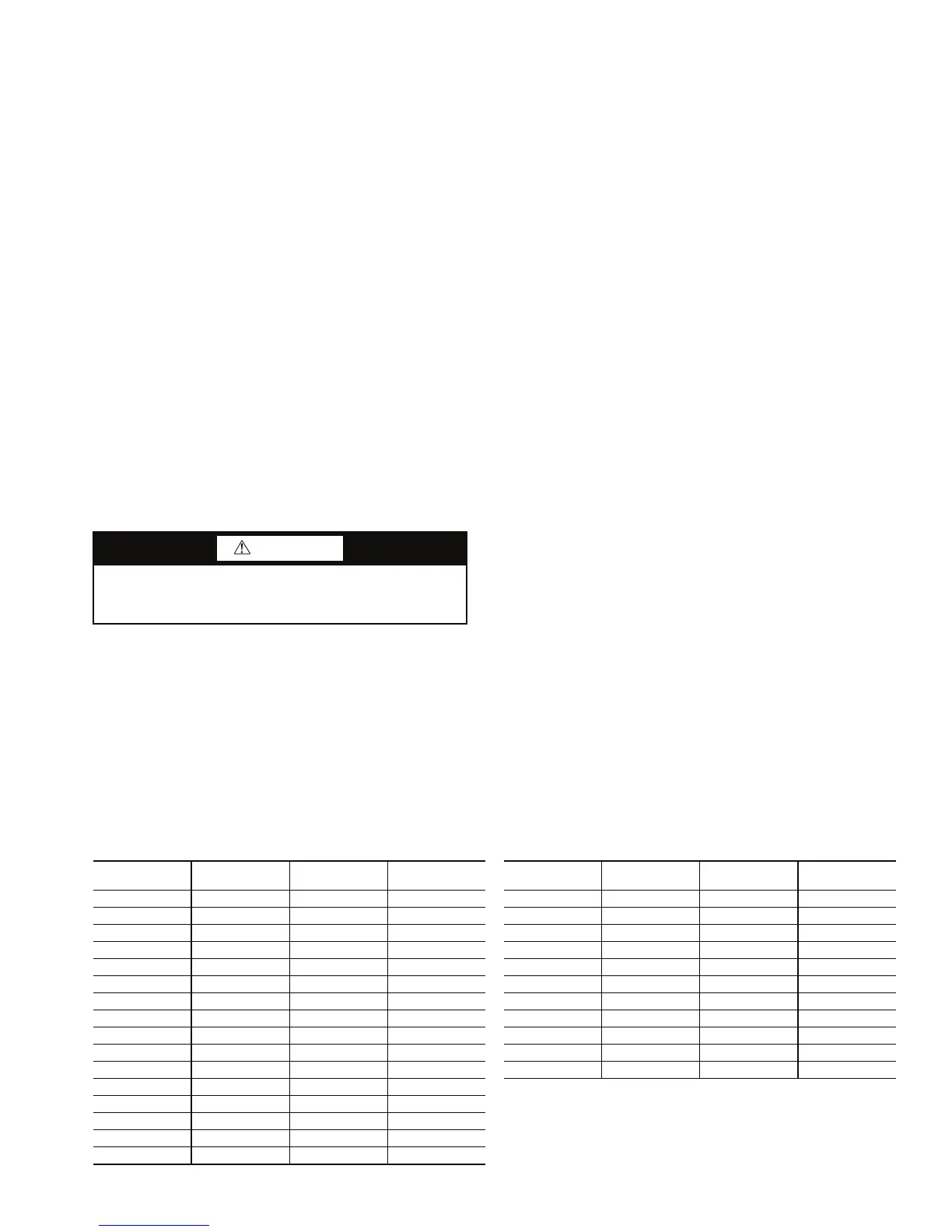

7. To determine the approximate refrigerant charge for the

machine, add the cooler charge to the applicable condens-

er charge as listed in Tables 3A and 3B.

Hot Alignment Check and Doweling — After the

machine has been running at about full load for 4 hours, its

components will have come up to steady state operating tem-

perature conditions and the final hot alignment check may be

made.

Realign component locations until angular and parallel

alignments are within coupling manufacturer's specified toler-

ances.

Dowel all equipment into place as soon as the hot alignment

check proves that the machine is within these running toleranc-

es. See Carrier Standard Service Techniques, Form SM-15,

Rev A, for these operations.

Operational Testing — When the chiller is in opera-

tion, and it is time to set the flows and confirm that the machine

is operating according to design conditions, a heat balance

must be determined. In brief, a heat balance is the sum of the

energy being absorbed by the cooler plus the energy supplied

through the driver (turbine, motor) compared with the energy

being discharged through the condenser.

Cooler Tons + Motor Tons = Condenser Tons

When these two items are equal it is certain that the readings

and measurements are accurate. The motor kW must be cor-

rected for motor efficiency and gear losses must be subtracted

from motor kW to get actual compressor input horsepower.

Motor kW is converted to equivalent tons by this formula:

Tons = kW / 3.515

Cooler and condenser tons: (for fresh water, specific heat

[sp ht] = 1 and specific gravity [sp gr] = 1)

Tons = (gpm * T * sp ht * sp gr) / 24

A perfect heat balance is 0, but this is practically impossible

to achieve. With laboratory quality instrumentation, less than a

2% heat balance at full load conditions should be achievable.

Greater than 5% should be regarded as very inaccurate and re-

quires further investigation of the start-up conditions.

Instruct Customer Operator — Ensure the opera-

tor(s) understand all operating and maintenance procedures.

Point out the various chiller parts and explain their function as

part of the complete system.

CONTROL PANEL

1. Internal safeties

2. Communication with chiller controls

3. Starter operational sequence

4. Current and voltage monitor operation

VFD

1. Detailed description of component, section, purpose, and

operation

2. Control section processor and access to screens

3. Procedures to switch from bypass to VFD operation (if

bypass equipped)

Table 3A — Typical 17DA Cooler and Condenser Charges (R-134a) (lb)

CAUTION

Excessive overcharge may cause liquid refrigerant carry-

over into the compressor, causing severe overload and pos-

sible compressor damage.

COOLER

SIZE

15-FT TUBES 18-FT TUBES 22-FT TUBES

CONDENSER

SIZE

15-FT TUBES 18-FT TUBES 22-FT TUBES

61 3,000 3,600 4,400 61 2,000 2,400 2,900

63 3,600 4,300 5,300 63 2,000 2,400 2,900

65 3,600 4,300 5,300 65 2,500 3,000 3,600

67 4,200 5,100 6,200 67 2,500 3,000 3,600

71 4,600 5,500 6,800 71 2,600 3,100 3,800

73 5,000 5,900 7,300 73 2,600 3,100 3,800

75 5,600 6,600 8,100 75 3,100 3,700 4,500

81 6,500 7,700 9,500 81 3,500 4,100 5,000

82 7,700 9,300 11,300 83 4,000 4,700 5,800

83 6,900 8,300 10,200 85 4,600 5,400 6,700

84 8,200 9,900 12,200 87 4,500 5,300 6,500

85 7,700 9,200 11,300

86 10,200 12,300 15,200

87 8,600 10,400 12,600

88 11,000 13,500 16,500

90 13,000 15,600 19,200

Loading...

Loading...