18

and a Linkage write. The CCN point OCCUPIED is forced via

an external device such as a ComfortID™ controller or a service

tool: when OCCUPIED is forced to YES, the unit is considered

occupied, when OCCUPIED is forced to NO, the unit is consid-

ered unoccupied. If the unit is being controlled by Linkage, the

occupancy is communicated and mapped to OCCUPIED as an

input. Linkage does not force the point, only write to it, therefore

a force applied to OCCUPIED will override it.

If OCCUPIED is not being forced or written to, proceed to the

level 2 priority.

LEVEL 2 PRIORITY

Level 2 is considered occupant interaction, and consists of

Timed Override and Remote Occupancy Switch. A timed over-

ride button press will override a remote occupancy switch if

both are installed for operation.

While using the programmed schedule, occupancy can be tempo-

rarily switched from unoccupied to occupied by pressing the over-

ride button for approximately 3 seconds on the T-55, T-56, or T-59

space temperature sensor. The length of the override period when

pressing the override button is determined by the Override Time

Limit (TIMED OVR LENGTH). The hours remaining in override

is displayed as Timed Override Hours (TIMED OVR HOURS).

This point can also be changed from the local display or network

to set or change the override period length.

Remote Occupancy Switch (REMOTE OCC SWITCH) can be

forced or configured for operation based on an actual switch.

The physical switch should be configured to either Normally

Open or Normally Closed when the user would like to control

the occupancy with an external switch. This switch is field-

supplied (24v, single pole, single throw [SPST]). There are two

possible configurations for the remote occupancy switch:

1. (REMOTE OCC TYPE = 0) Normally Open Switch

2. (REMOTE OCC TYPE = 1) Normally Closed Switch

If the switch is configured to No Switch (REMOTE OCC

CHAN = None), the switch input value will be ignored and soft-

ware will proceed to level 3 priority. For each type of switch, the

appropriate configuration and states are listed in Table 12.

LEVEL 3 PRIORITY

The following occupancy options are determined by the state of

Occupancy Schedule Number (SCHEDULE NUMBER) and

the Global Schedule Broadcast (BROADCAST SCHEDL?).

1. (SCHEDULE NUMBER = 0) The unit is always consid-

ered occupied and the programmed schedule is ignored.

This is the factory default.

2. (SCHEDULE NUMBER = 1-64) Follow the local pro-

grammed schedule. Schedules 1 to 64 are local within the

controller. The unit can only store one local schedule and

therefore changing this number only changes the title of

the schedule table.

3. (SCHEDULE NUMBER = 65-99) Follow the global pro-

grammed schedule. If the unit is configured as a Global

Schedule Broadcaster (BROADCAST SCHEDL? = YES),

the unit will follow the unit’s programmed schedule and

broadcast the schedule so that other devices programmed

to follow this schedule number can receive the schedule. If

the unit is not programmed as a Global Schedule Broad-

caster (BROADCAST SCHEDL? = NO), the unit will

receive broadcasted schedules from a unit programmed to

broadcast this schedule number.

HUMIDITY DEMAND

When the unit is configured for either a Humidistat input

(HUMSTAT CHANNEL) or Space Humidity Sensor (SPRH

SENS CHANNEL), the level 5 demand in Table 9 will include

a determination of dehumidification demand.

HUMIDISTAT

When receiving an active input from the Humidistat (HUMID-

ISTAT), dehumidification will be demanded.

SPACE RELATIVE HUMIDITY

On units with a relative humidity sensor, when the received value

of space relative humidity (SPRH LEVEL) has exceeded the hu-

midity set point (SPRH SET POINT), dehumidification will be

demanded. This demand will remain until the space relative hu-

midity has fallen below the humidity set point by more than the

humidity set point deadband (SPRH DEADBAND). This would

come from the space humidity sensor or building network.

Indoor Fan Operation

These units use the Staged Air Volume (SAV™) method of

controlling the supply fan for a typical constant volume rooftop

unit. This control method employs a variable frequency drive

(VFD) to operate the supply fan at different speeds in order to

achieve energy savings through reduced fan power. This meth-

od is specifically not concerned with controlling static pressure

in the supply duct, but rather with setting different fan speeds

for different operating conditions, such as ventilation mode or

part-load mechanical cooling.

The SAV function is NOT a Variable Air Volume (VAV) func-

tion. The fan adapts its speed to one of eight options based on

mode and current state to satisfy a demand. The eight speeds

consist of: off (0%) and seven configurable values. The seven

configurable fan speeds are: Maximum Speed (MAXIMUM

IDF SPEED), Ventilation (VENT IDF SPEED), Heating

(HEATING IDF SPD), Free Cool (FREE COOL IDF SPD),

Mechanical Low Cooling (LOW COOL IDF SPD), Mechanical

Medium Cooling (MED COOL IDF SPD), and Mechanical

High Cooling (HIGH COOL IDF SPD), The VFD is powered

direct from the distribution block or circuit breaker (CB) and is

always on with power applied unless the CB is tripped. When

the thermostat or space sensor control conditions require the fan

on, the VFD will then ramp to desired speed. Fan speed is al-

ways calculated by evaluating the current applicable conditions.

Each fan speed condition is evaluated independently, and the

highest fan speed is used. For example, if a cooling call occurs

during Ventilation mode, the unit mode will transition to cooling

but the fan speed is set to the higher of the two (VENT IDF

SPEED or LOW COOL IDF SPD). Refer to the speed configu-

rations below for when the fan will run at the various speeds.

DIRECT DRIVE UNITS

Alternately, 48/50LC*04-06 units can have either a direct drive

Electronic Commutated Motor (ECM) fan system or a belt drive

motor powered by a Variable Frequency Drive (VFD). An IDF-

TYPE=1 indicates a unit with VFD, while an IDFTYPE=2 indi-

cates a direct drive system. Refer to the unit product data for fan

performance tables and physical data. On direct drive units, the

ECM has 5 speed taps to allow a range of fan performance. The

control has 3 output wires to connect to 3 different taps. At the

factory, the low and high speed wires are connected to the first

and second speed taps, respectively. The ventilation speed tap is

disconnected. The speed taps increase in speed the higher the tap

number, so tap 1 is the lowest speed and tap 5 is the highest

speed. If the low and high speed wires are moved to higher taps,

the ventilation speed wire can be wired into the motor. To

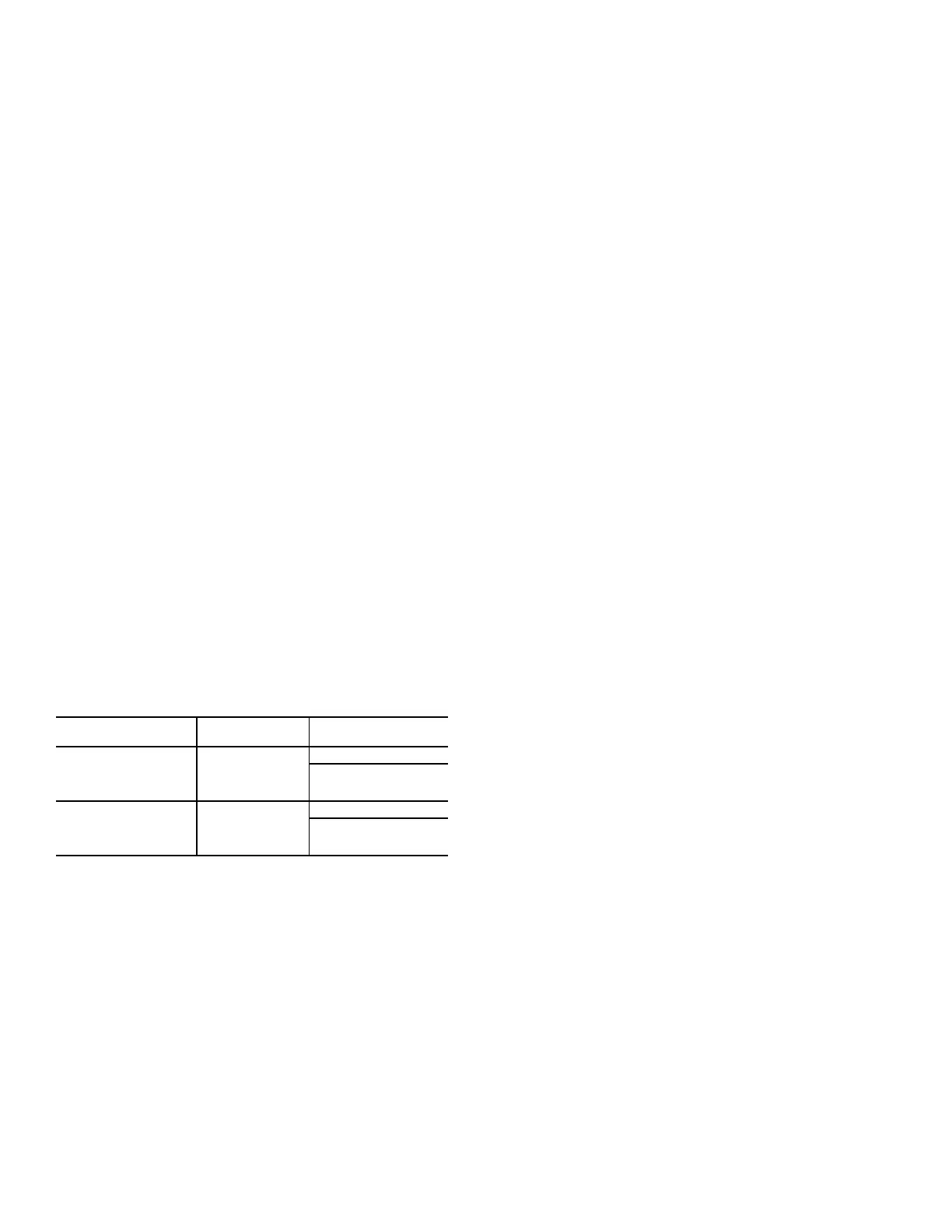

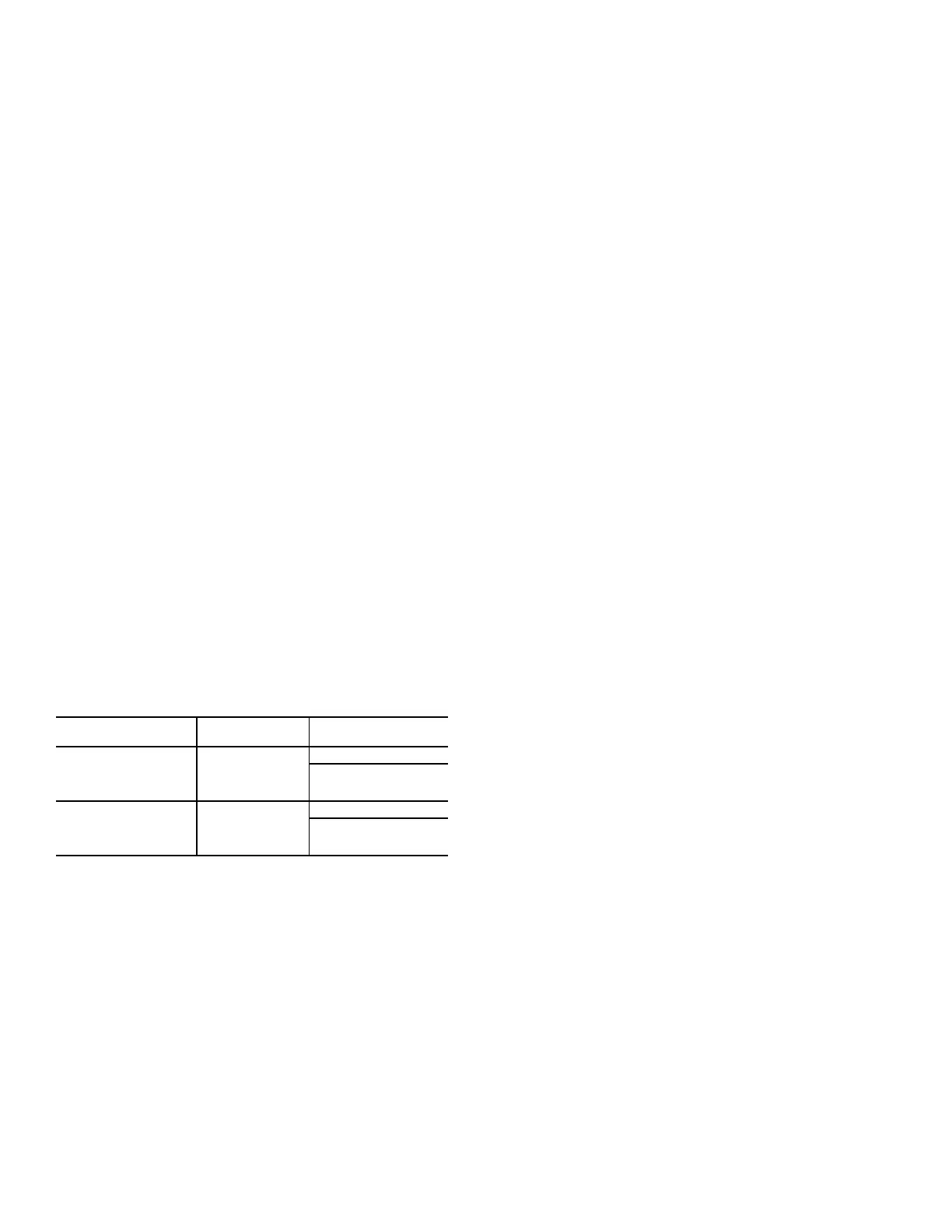

Table 12 — Switch Configurations

TYPE OF SWITCH

SWITCH

CONFIGURATION

STATE OF SWITCH

AND OF OCCUPANCY

Occupied when closed

or

Unoccupied when

open

Normal Open (0)

Open and Unoccupied

Closed and Occupied

Occupied when open

or

Unoccupied when

closed

Normal Closed (1)

Open and Occupied

Closed and Unoccupied

Loading...

Loading...