40

Control Module Communication

RED LED

Proper operation of the MBB control board can be visually

checked by looking at the red status LED. When operating cor-

rectly, the red status LED should blink at a rate of once every

2 seconds. If the red LED is not blinking, verify that correct

power is being supplied. A blinking red LED at the rate of once

per second means that software is not loaded on the board. Al-

so, be sure that the board is supplied with the current software.

If necessary, reload current software. A board LED that is lit

continuously should be replaced.

GREEN LED

The MBB has one green LED. The Local Equipment Network

(LEN) LED should always be blinking whenever power is on.

If LEN LED is not blinking, check LEN connections for poten-

tial communication errors (MBB J15, J16, J17, and on the Dis-

play J2). Communication between modules is accomplished by

a 3-wire sensor bus. These 3 wires run in parallel from module

to module. The MBB J17 and Display J2 connectors provide

both power and communication directly at the connector for

accessories like the Navigator™ display. The MBB J15 con-

nector provides a LEN interface to the indoor fan VFD.

YELLOW LED

The MBB has one yellow LED which is used to indicate Build-

ing Automated System (BAS) communication activity. The

LED will blink when the MBB transmits a message on the bus.

Communication Failures

If the Indoor Fan VFD or Navigator display Communication

Failure or the green or yellow LED’s do not flash on the boards,

then the problem could be the communication chip on one of the

control boards (MBB). Use an ohm meter to measure the resis-

tance on the communication pins of the boards to determine if

the board is bad. If the reading is less then half the value indicat-

ed in Table 17, then the board needs to be replaced.

Cooling Troubleshooting

Use the SystemVu™ Display or a CCN device to view the

cooling status display and the cooling diagnostic display (see

Appendices) for information on the cooling operation. Check

the current alarms and alarm history for any cooling alarm

codes and correct any causes. (See Table 16.) Verify any

unique control configurations per installed site requirements or

accessories.

If alarms conditions are corrected and cleared, operation of the

compressors and fans may be verified by using the Service Test

mode. (See Table 4.) See Table 18 for general cooling service

analysis.

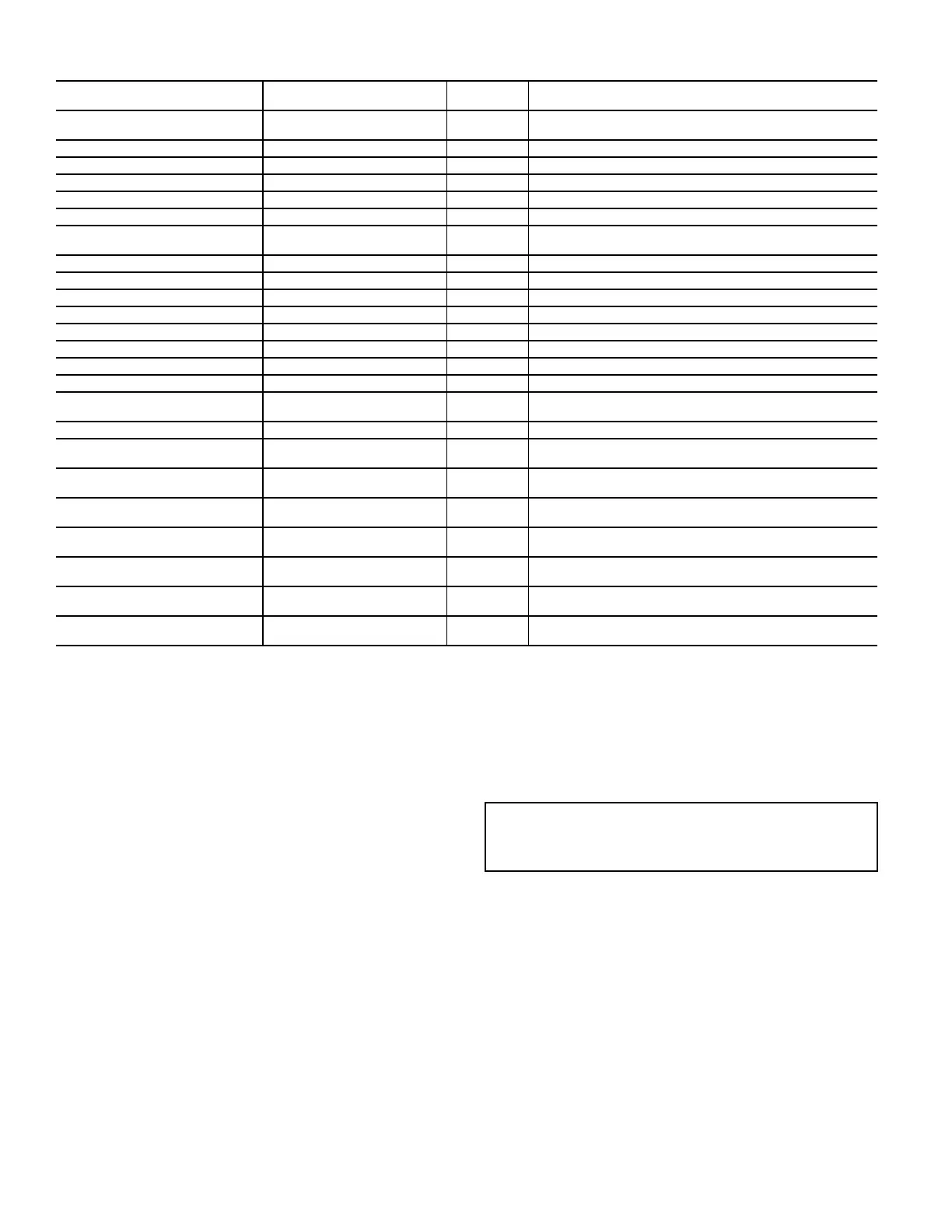

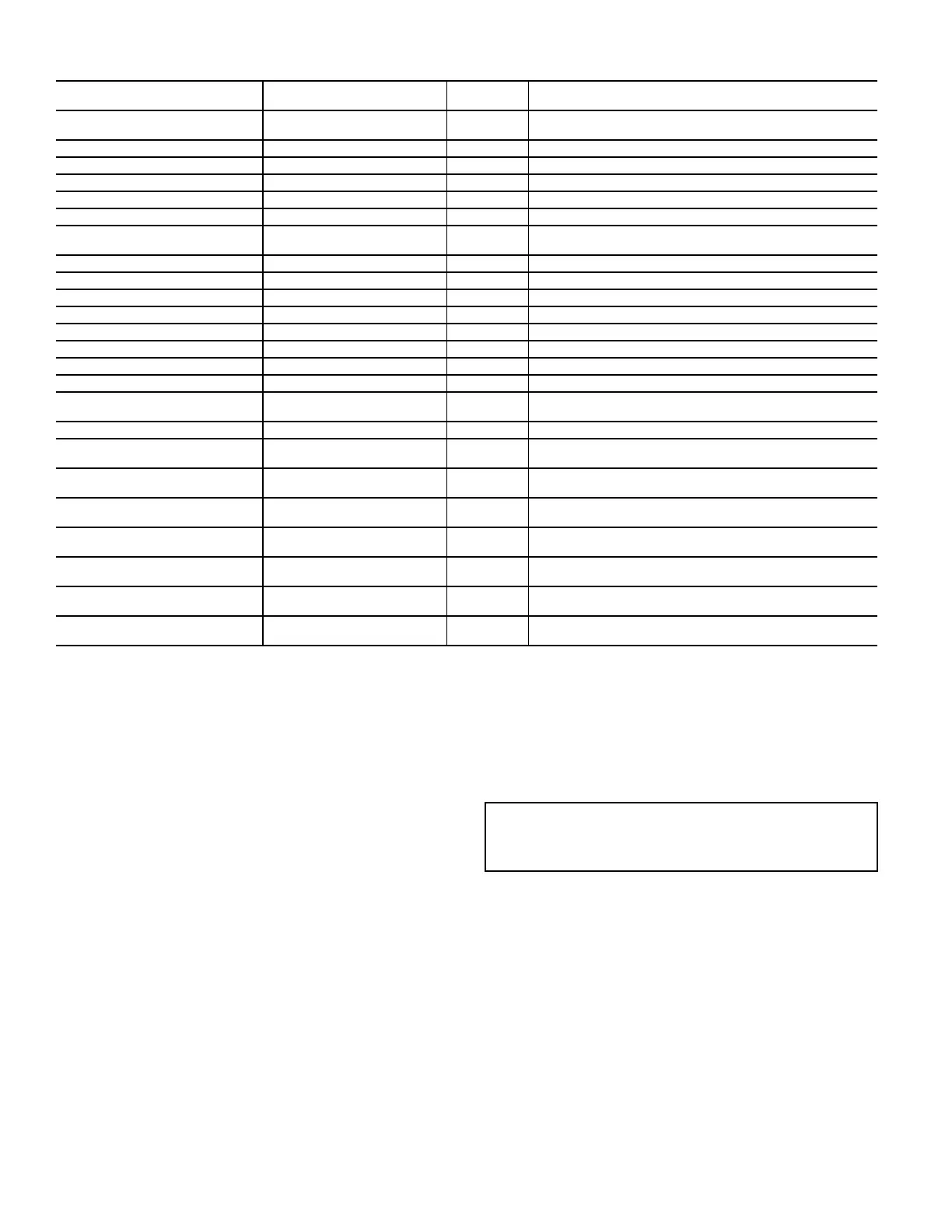

A606-IDF VFD VOLTAGE

WARNING

IDF speed reduced Automatic Motor improper size, motor overload, or configuration errors.

A607-IDF VFD CURRENT LIMIT IDF speed reduced Automatic Motor improper size, motor overload, or configuration errors.

A608-IDF VFD WARNING IDF speed reduced Automatic Motor improper size, motor overload, or configuration errors.

F611-IDF VFD EARTH FAULT Unit Shutdown Automatic VFD fault, refer to VFD section

F612-IDF VFD CTL WORD LOSS Unit Shutdown Automatic VFD fault, refer to VFD section

F613-IDF VFD OVER CURRENT Unit Shutdown Automatic VFD fault, refer to VFD section

F614-IDF VFDMOTOR OVER

TEMP

Unit Shutdown Automatic VFD fault, refer to VFD section

F615-IDF VFD OVERLOAD Unit Shutdown Automatic VFD fault, refer to VFD section

F616-IDF VFD UNDER VOLTAGE Unit Shutdown Automatic VFD fault, refer to VFD section

F617-IDF VFD OVER VOLTAGE Unit Shutdown Automatic VFD fault, refer to VFD section

F618-IDF VFD SHORT CIRCUIT Unit Shutdown Automatic VFD fault, refer to VFD section

F619-IDF VFD MAIN PHASE LOSS Unit Shutdown Automatic VFD fault, refer to VFD section

F620-IDF VFD PHASE U LOSS Unit Shutdown Automatic VFD fault, refer to VFD section

F621-IDF VFD PHASE V LOSS Unit Shutdown Automatic VFD fault, refer to VFD section

F622-IDF VFD PHASE W LOSS Unit Shutdown Automatic VFD fault, refer to VFD section

F623-IDF VFD CONTROL

VOLTAGE

Unit Shutdown Automatic VFD fault, refer to VFD section

F624-IDF VFD SUPPLY VDD Unit Shutdown Automatic VFD fault, refer to VFD section

A700-ECON NOT MODULATING Alert Generated Automatic

No economizer motion. Check damper blades, gears, and

actuator. Actuator direction control switch (CCW, CW) wrong.

A701-ECON STUCK CLOSED Alert Generated Automatic

No economizer motion. Check damper blades, gears, and

actuator. Actuator direction control switch (CCW, CW) wrong.

A702-ECON STUCK OPEN Alert Generated Automatic

No economizer motion. Check damper blades, gears, and

actuator. Actuator direction control switch (CCW, CW) wrong.

A703-ECON MECH

DISCONNECTED

Alert Generated Manual

No economizer motion. Check damper blades, gears, and

actuator. Actuator direction control switch (CCW, CW) wrong.

A710-ECON NOT COOLING Alert Generated Automatic

No economizer motion. Check damper blades, gears, and

actuator. Actuator direction control switch (CCW, CW) wrong.

A711-ECON IMPROPER COOLING Alert Generated Automatic

No economizer motion. Check damper blades, gears, and

actuator. Actuator direction control switch (CCW, CW) wrong.

A712-EXCESSIVE OUTDOOR AIR Alert Generated Automatic

No economizer motion. Check damper blades, gears, and

actuator. Actuator direction control switch (CCW, CW) wrong.

Table 16 — SystemVu™ Controller Alarm Codes (cont)

FAULT OR ALERT

ACTION TAKEN

BY CONTROL

RESET

METHOD

PROBABLE CAUSE

IMPORTANT: The resistive values should be read when

the board is powered off, the unit is locked out, and board

connectors are disconnected.

Loading...

Loading...