29

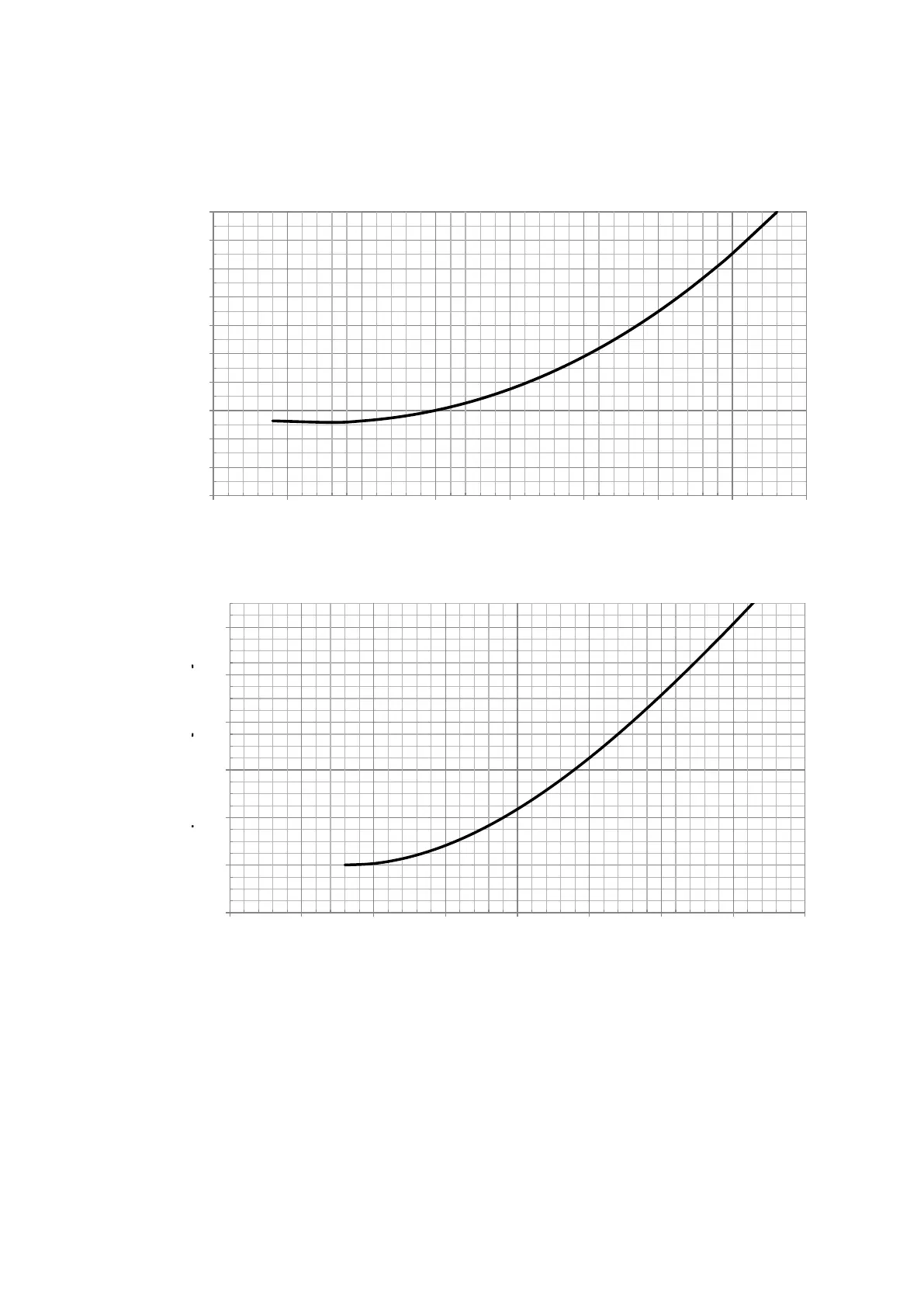

8.2 - NPSH (Net Positive Suction Head) required ;

Hydronic module option

Design hydronic circuit in order to guarantee that NPSH

(Net Positive Suction Head) is higher or equal to required

NPSH + 50 kPa.

0

10

20

30

40

50

60

70

80

90

100

0 5 10 15 20 25 30 35 40

Required NPSH [ kPa abs ]

Flow rate [L/s]

Low pressure pumps (options 116T/116U)

Low pressure pumps (options 116T/116U)

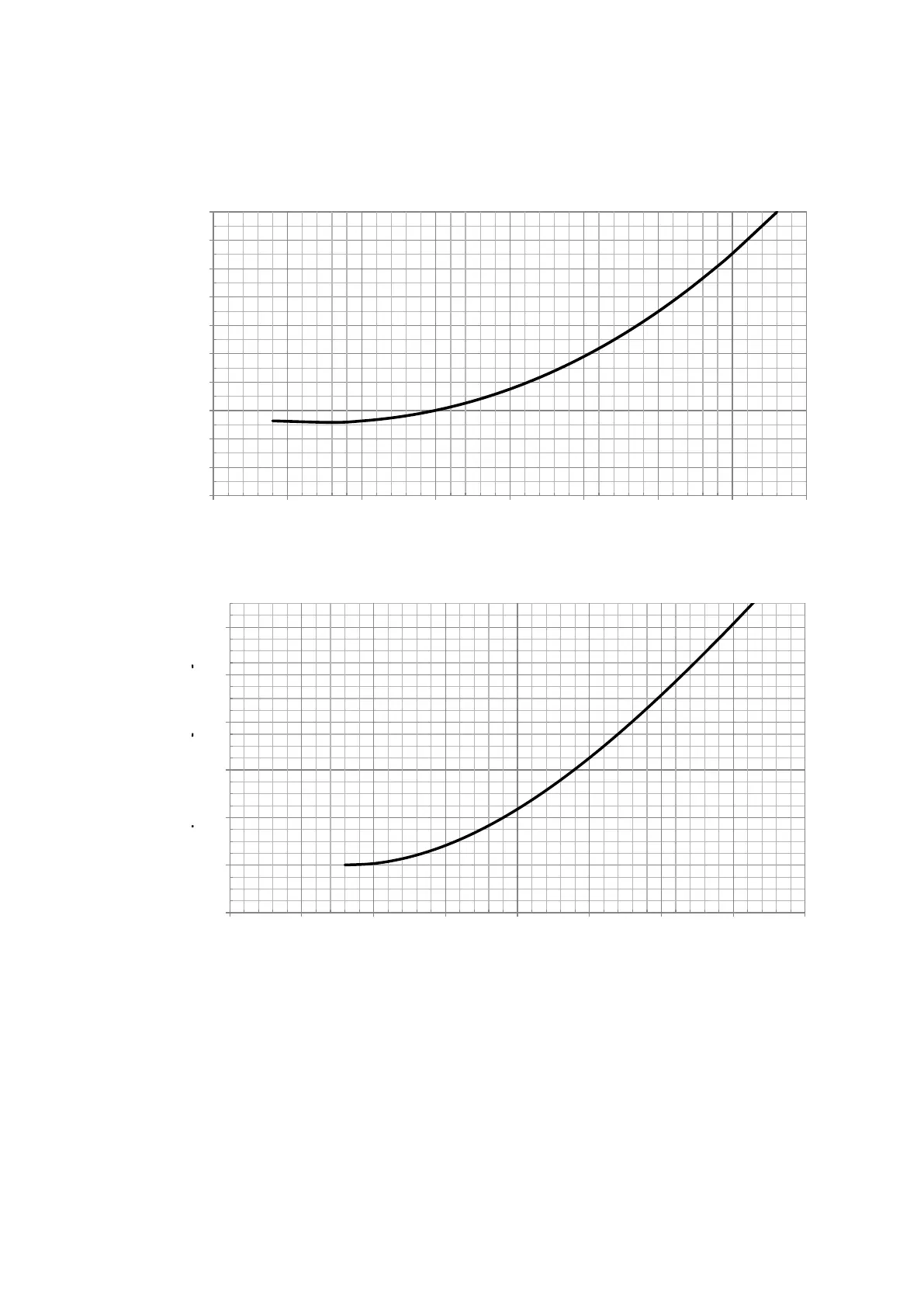

Required NPSH [ kPa abs

Flow rate [L/s]

0

20

40

60

80

100

120

0 5 10 15 20 25 30 35 40

Required NPSH [ kPa abs ]

Flow rate [L/s]

High pressure pumps (options 116R/116S)

High pressure pumps (options 116R/116S)

Required NPSH [ kPa abs ]

Flow rate [L/s]

Units with hydronic module enable direct monitoring of

ow rate and cooling capacity through IHM (refer to

30XAV-ZE control manual).

Fluid pressure is measured by pressure sensors tted at

pump inlet and unit outlet. The system calculates the ow

rate corresponding to measured differential pressure.

Combined with temperature difference between

evaporator inlet and outlet, this ow rate calculation

permits to provide a monitoring of cooling capacity.

Calculations are only applicable with fresh water. In case

of brine solution (ex: glycol) other than fresh water, ow

and cooling capacity provided won't be accurate.

These data are given for indicative purpose to user and

may vary depending on hydronic circuit fouling and

proper operation of the pump. Carrier does not undertake

the accuracy of this information.

Loading...

Loading...