EWAQ016~064BAW + EWYQ016~064BAW

Packaged air-cooled water chiller

4PW70082-1C – 2013.07

Installation and operation manual

10

4.5. Perform the water piping work

4.5.1. Connecting the water pipes

Water connections must be made in accordance with all applicable

legislations and the outlook drawing delivered with the unit,

respecting the water in- and outlet.

If dirt gets in the water circuit, problems may occur. Therefore, always

take into account the following when connecting the water circuit:

■ Use clean pipes only.

■ Hold the pipe end downwards when removing burrs.

■ Cover the pipe end when inserting it through a wall so that no

dust and dirt enter.

■ Use a good thread sealant for the sealing of the connections.

The sealing must be able to withstand the pressures and

temperatures of the system, it must also be resistant to the used

glycol in the water.

■ When using non-brass metallic piping, make sure to insulate

both materials from each other to prevent galvanic corrosion.

■ Make sure to provide a proper drain for the pressure relief valve.

■ Because brass is a soft

material, use appropriate tooling

for connecting the water circuit.

Inappropriate tooling will cause

damage to the pipes.

■ For correct operation of the

system, a regulating valve must

be installed in the water system.

The regulating valve is to be used to regulate the water flow in

the system (field supply).

4.5.2. Installing the shut-off valve kit

Refer to figure 12.

1 Adapter piece

2 Shut-off valve

4.5.3. Insulating the water pipes

The complete water circuit, inclusive all piping, must be insulated to

prevent condensation during cooling operation and reduction of the

heating and cooling capacity as well as prevention of freezing of the

outside water piping during winter time. The thickness of the sealing

materials must be at least 13 mm with λ=0.039 W/mK in order to

prevent freezing of the outside water piping at ambient temperature

of –15°C.

If the temperature is higher than 30°C and the humidity is higher than

RH 80%, then the thickness of the sealing materials should be at

least 20 mm in order to avoid condensation on the surface of the

sealing.

4.5.4. Check the water volume and expansion vessel

pre-pressure

The unit is equipped with an expansion vessel of 12 litre which has a

default pre-pressure of 1 bar.

To assure proper operation of the unit, the pre-pressure of the

expansion vessel might need to be adjusted and the minimum and

maximum water volume must be checked.

1 Check that the minimum total water volume in the installation,

excluding the internal water volume of the unit, is according to

the table.

Refer to "6.1. Technical specifications" on page 24 to know the

internal water volume of the unit.

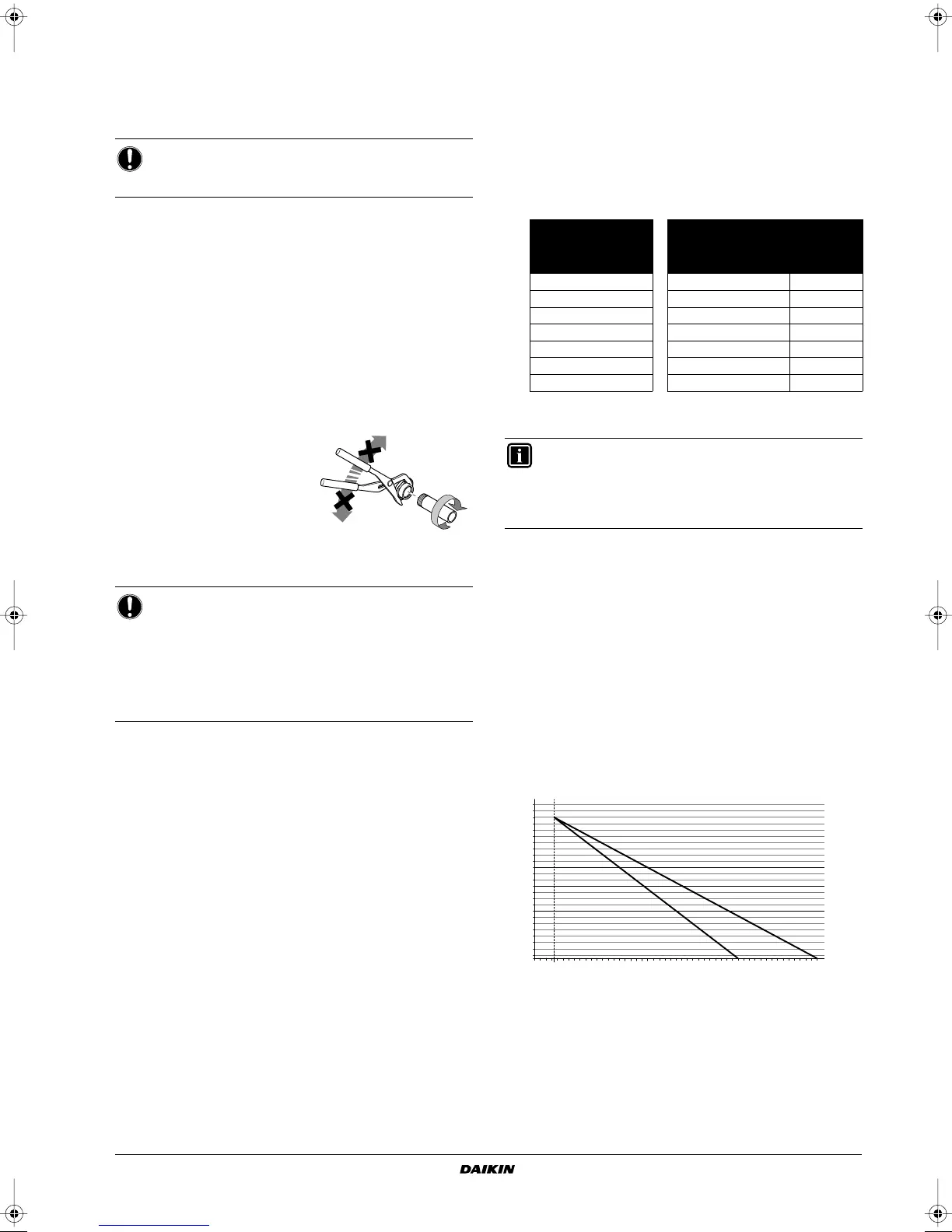

2 Calculating the pre-pressure of the expansion vessel

The pre-pressure (Pg) to be set depends on the maximum

installation height difference (H) and is calculated as below:

Pg=(H/10+0.3) bar

3 Checking the maximum allowed water volume

To determine the maximum allowed water volume in the entire

circuit, proceed as follows:

1 Determine for the calculated pre-pressure (Pg) the

corresponding maximum water volume using the graph

below.

2 Check that the total water volume in the entire water circuit is

lower than this value.

If this is not the case, the expansion vessel inside the unit is too

small for the installation. Solution: Install an additional expansion

vessel in the field piping.

figure "Maximum allowed water volume"

NOTICE

Be careful not to deform the unit piping by using excessive

force when connecting the piping.

NOTICE

■ The unit is only to be used in a closed water system.

Application in an open water circuit can lead to

excessive corrosion of the water piping.

■ Never use Zn-coated parts in the water circuit.

Excessive corrosion of these parts may occur as

copper piping is used in the unit's internal water

circuit.

EWAQ

Minimum

total water

volume (l)

EWYQ

Minimum total water volume

(l)

Cooling Cooling Heating

016 33 016 33 76

021 33 021 33 76

025 33 025 33 76

032 33 032 33 110

040 66 040 66 152

050 66 050 66 152

064 66 064 66 220

INFORMATION

In most applications this minimum water volume will have a

satisfying result.

In critical processes or in rooms with a high heat load

though, extra water volume might be required.

pre-pressure = pre-pressure

maximum volume = maximum volume (water or water + glycol)

A = system without glycol

B = system with 20% propylene glycol

C = Default

(Refer to Caution: "Use of glycol" on page 11)

C

0.3

0.5

1

1.5

2

2.5

100500 34 150 200 250 300 350 400 450

[l]

maximum volume

[bar]

pre-pressure

B A

500

BA

4PWEN70082-1C.book Page 10 Wednesday, September 25, 2013 7:31 AM

Loading...

Loading...