www.DaikinApplied.com 17 IM 1285-4 • MICROTECH III

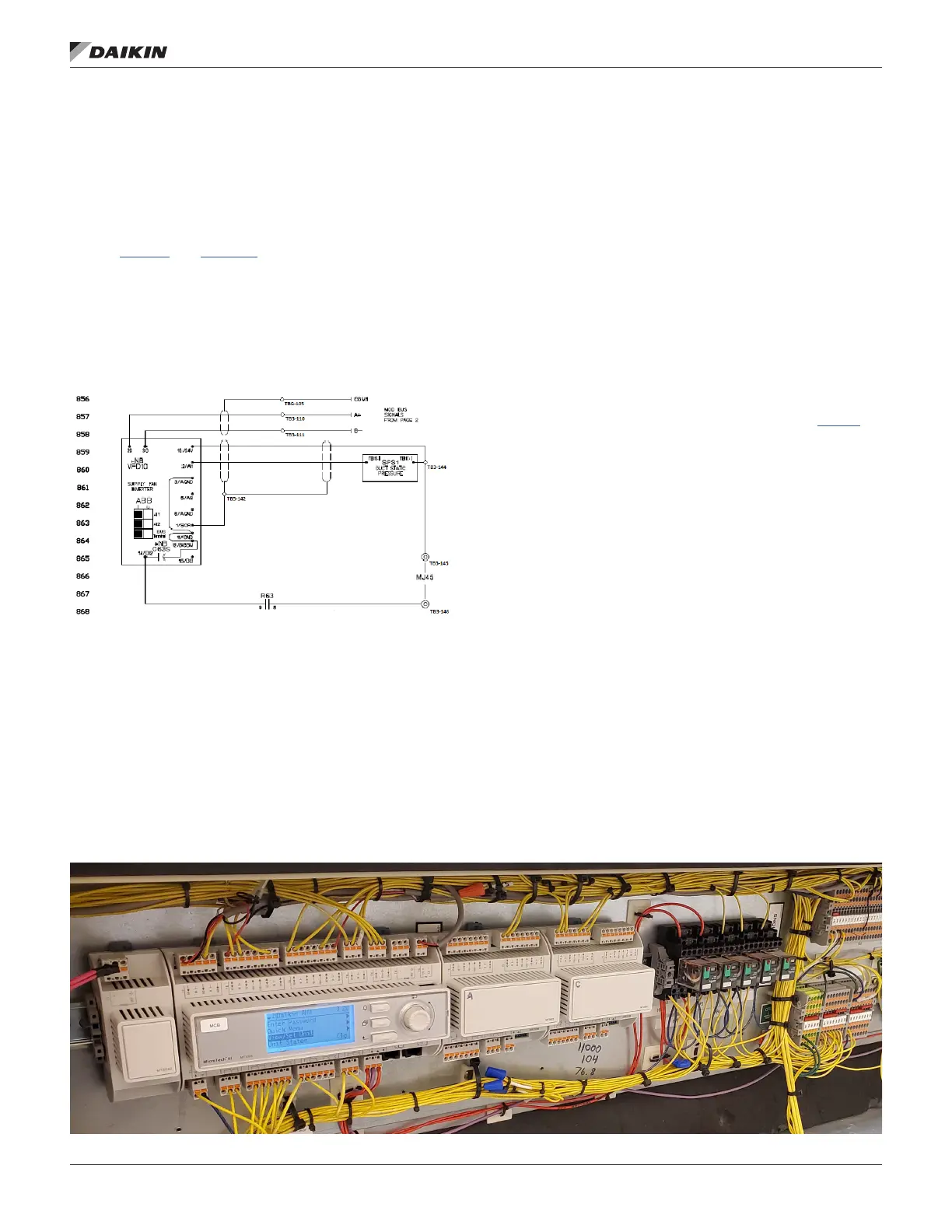

A VFD on the Supply Fan motor is required if the unit is

designed for a Variable Air Volume application. The MT III and

VFD communicate drive status and speed through Modbus.

The jumpers shown on VFD are necessary. See an example of

the ABB VFD wiring diagram in Figure 23. Wiring for Schneider

and Danfoss VFDs can be found in Appendix G. Refer to

manual OM 844 and OM 1190 for information on Schneider

and ABB VFDs, respectively.

Once the VFD is installed and wired correctly,

the parameters for the VFD must be set. See

“Programming the VFD” on page 17 in this manual

for instructions.

Figure 23: VFD Wiring Diagram

If there is an ABB, Schneider or Danfoss VFD installed, the

Duct Static Pressure sensor wires directly to the VFD. The

4-20mA output signal from the DSP sensor is wired to the AI1

terminal on the ABB VFD. The MT III reads in the DSP sensor

signal through Modbus and sends a speed signal to the VFD

in order to maintain the DSP set point. See Figure 23. See

Appendix G on page 40 for DSP wiring on Schenider and

Danfoss VFDs.

Once the MT III and all of the auxiliary electrical devices are

installed and wired, the controller will need to be programmed.

There are three tasks when programming the MT III controller:

Verify and Update Software Code, Set Unit Conguration, and

Set Parameters.

Verify and Update Software Code

The unit’s software code must be updated to the newest code.

See the SIL in Appendix C on page 23 for instructions on

how to upload code to the MT III controller.

Set Unit Conguration

Each MT III has a unique Unit Conguration that must be set

according to the unit’s features and capabilities. See IM 919 for

instructions and unit conguration options.

Set Parameters

After the software code is updated and the unit conguration is

set, the parameters on the MT III will need to be set.

After the VFD is installed and wired, the parameters need to be

set. See charts in Appendix D through Appendix F and set the

parameters depending on the type of drive.

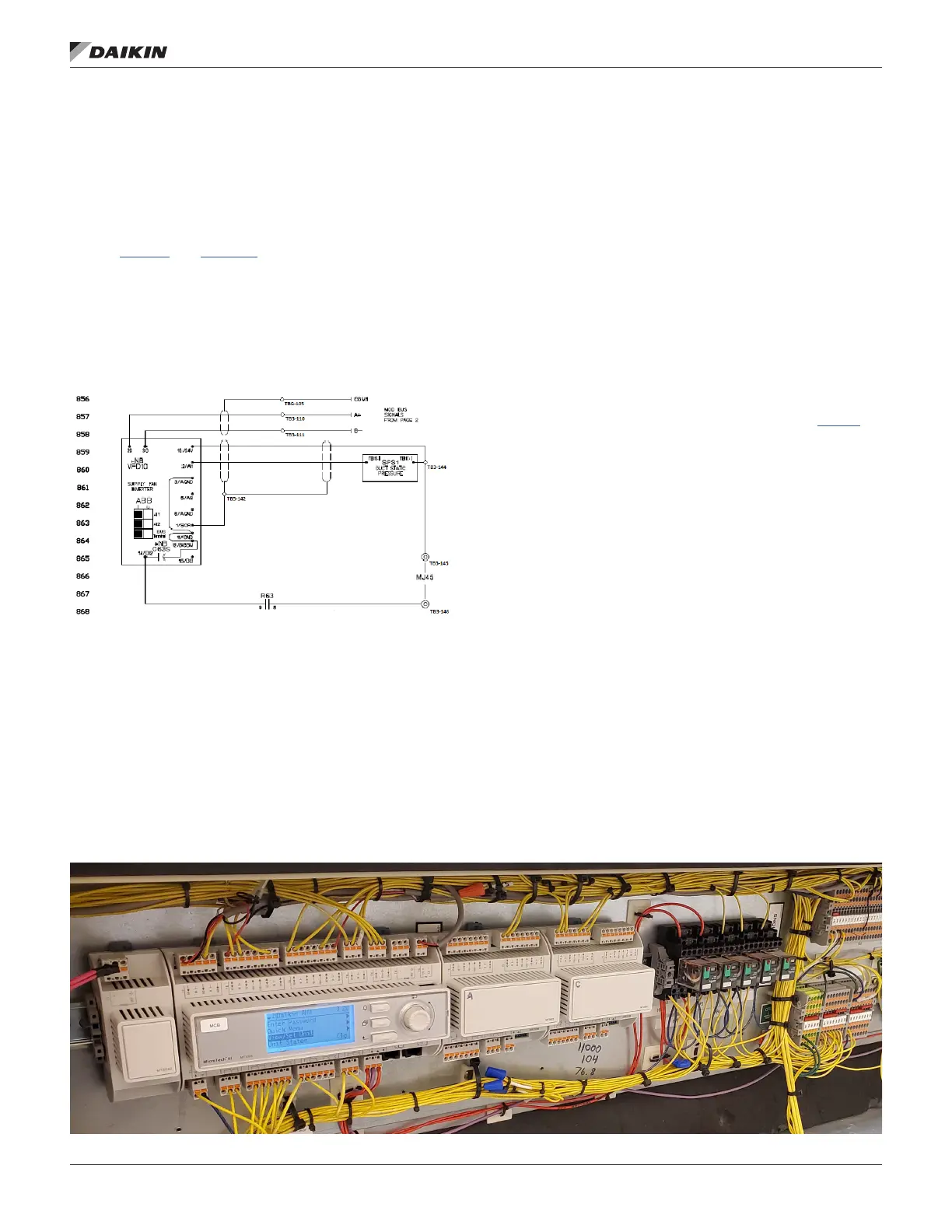

Figure 24 shows a sample control panel after the conversion

is complete. Be aware that the image below does not include

the white wire organizers or standard terminal blocks used in

this manual. The image should be used as a reference. The

nal product will vary slightly depending on the technician and

job site.

Figure 24: Completed Conversion

Loading...

Loading...