IM 972-2 • MAVERICK I ROOFTOP SYSTEMS 14 www.DaikinApplied.com

Wiring

Power Supply

DANGER

Power supply to the unit must be disconnected before making eld

connections. To avoid electrical shock, personal injury or death, be sure to

rigorously adhere to eld wiring procedures regarding proper lockout and

tagout of components.

1. All wiring should be made in accordance with the

National Electrical Code. Consult the local power

company to determine the availability of sucient power

to operate the unit. Check the voltage at power supply to

make sure it corresponds to the unit’s RATED VOLTAGE

REQUIREMENT. Install a branch circuit disconnect near

the rooftop, in accordance with the N.E.C., C.E.C. or

local codes.

2. It is important that proper electrical power is available at

the unit. Voltage should not vary more than 10% from

that stamped on the unit nameplate. On three phase

units, phases must be balanced within 3%.

3. For branch circuit wiring (main power supply to unit

disconnect), the minimum wire size for the length of

run can be determined from Table 4 using the circuit

ampacity found on the unit rating plate. Use the smallest

wire size allowable from the unit disconnect to the unit.

Wire size based on 75°C rated wire insulation for 1%

voltage drop.

4. For more than 3 conductors in a raceway or cable, see

the N.E.C. (C.E.C. in Canada) for derating the ampacity

of each conductor.

5. For through-the-base wiring entry, reference Figure

15. All ttings and conduit are eld-supplied for this

application. Reference Table 5 for proper hole and

conduit size.

IMPORTANT: This unit is approved for use with copper

conductors only connected to unit contactor. Warranty will be

voided if aluminum wire is connected to unit contactor.

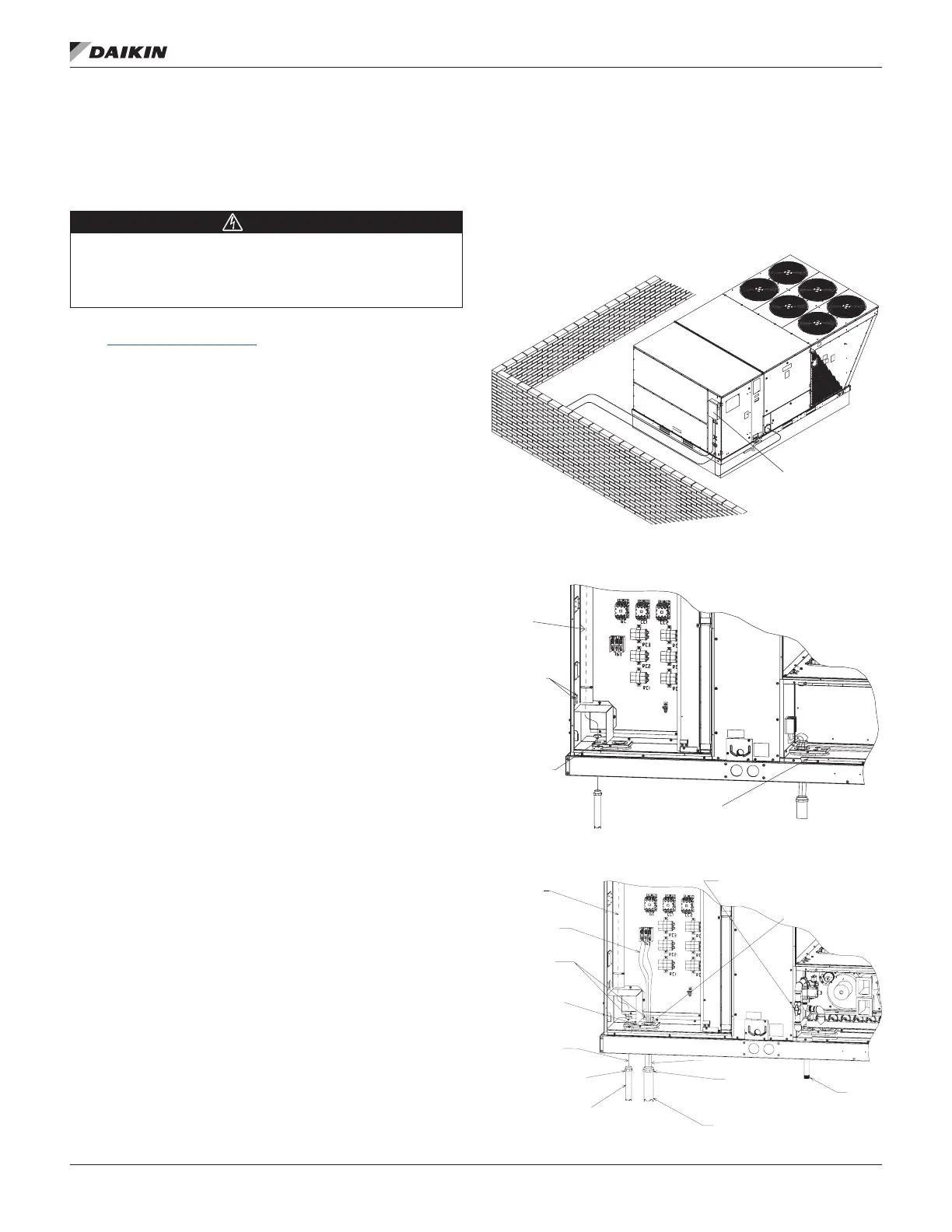

Figure 13: Recommended Branch Circuit Disconnect

Location

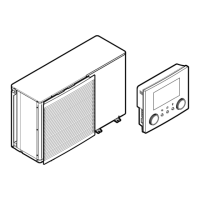

Figure 14: Base Entry Locations (Cooling Only)

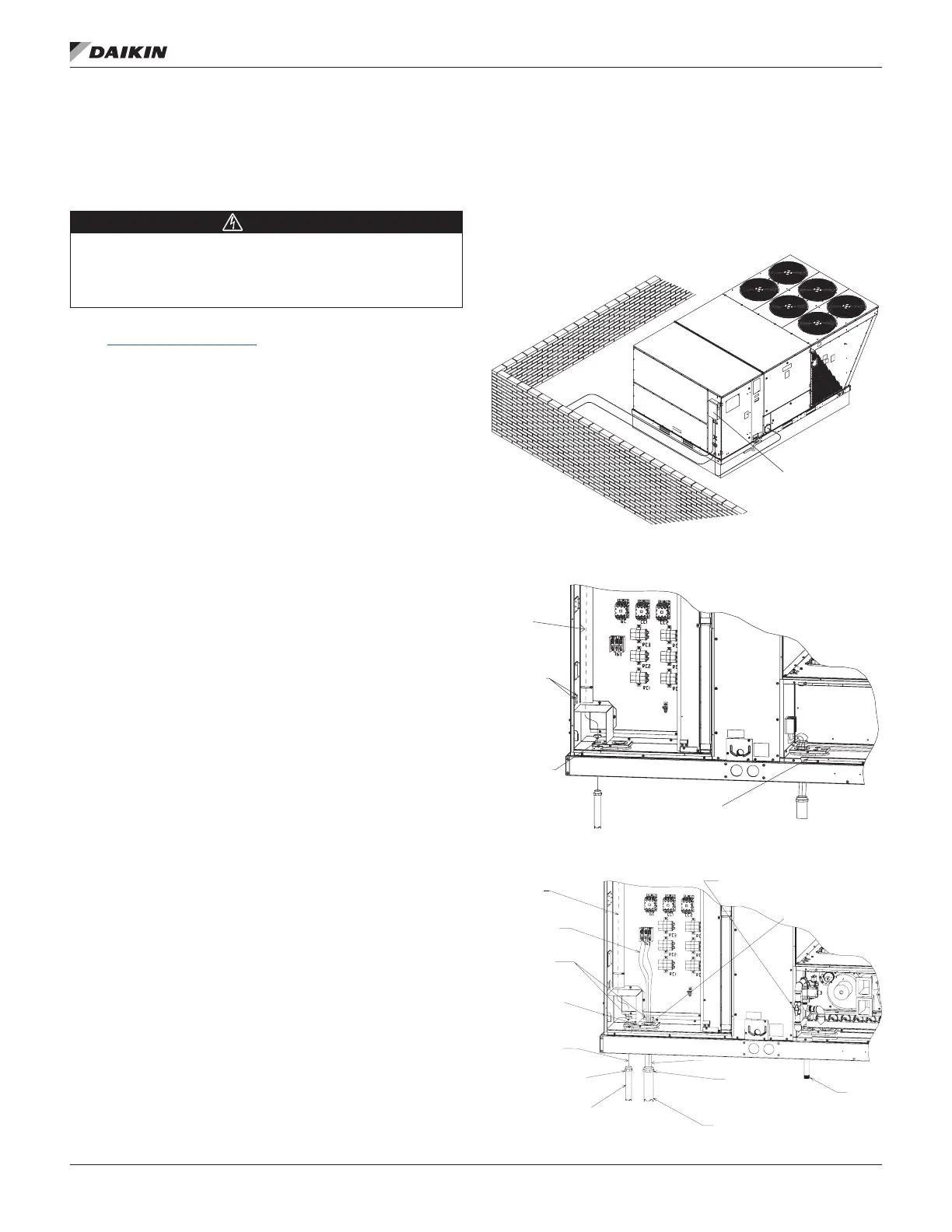

Figure 15: Base Entry Locations (Gas Heat)

DISCONNECT

RUN THERMOSTAT

WIRINGIN THIS

CHASETO

CONTROL

BOARD

(2) CAP PLUGS

BASE

CONTROL

ENTRY

BASE

POWER

ENTRY

POWERWIRES

FROM DISCONNECT

TO TERMINAL BLOCK

WASHERS

CONTROL VOLTAGE

KNOCKOUT

WIRE FROM

ZONE THERMOSTAT

STRAIGHT CONDUIT

FITTING

CONDUITFRO M

ZONE THERMOSTAT

CONDUIT FROM

POWER SUPPLY

SIZED PERCHART

STRAIGHTCONDUIT

FITTING SIZED

PERCHART

WIRE SIZE FROM

MIN. CIRCUITAMPACITY

CUT HOLE

SIZED PER CHART

OR USEKNOCK OUT

GASLINE

EXTERNALMANUALGAS

SHUT-OFF VALVE

RUNTHERMOSTAT

WIRING IN THIS

TO CONTROL

BOARD

Loading...

Loading...