27

12.6.2 Connection of wiring to terminals

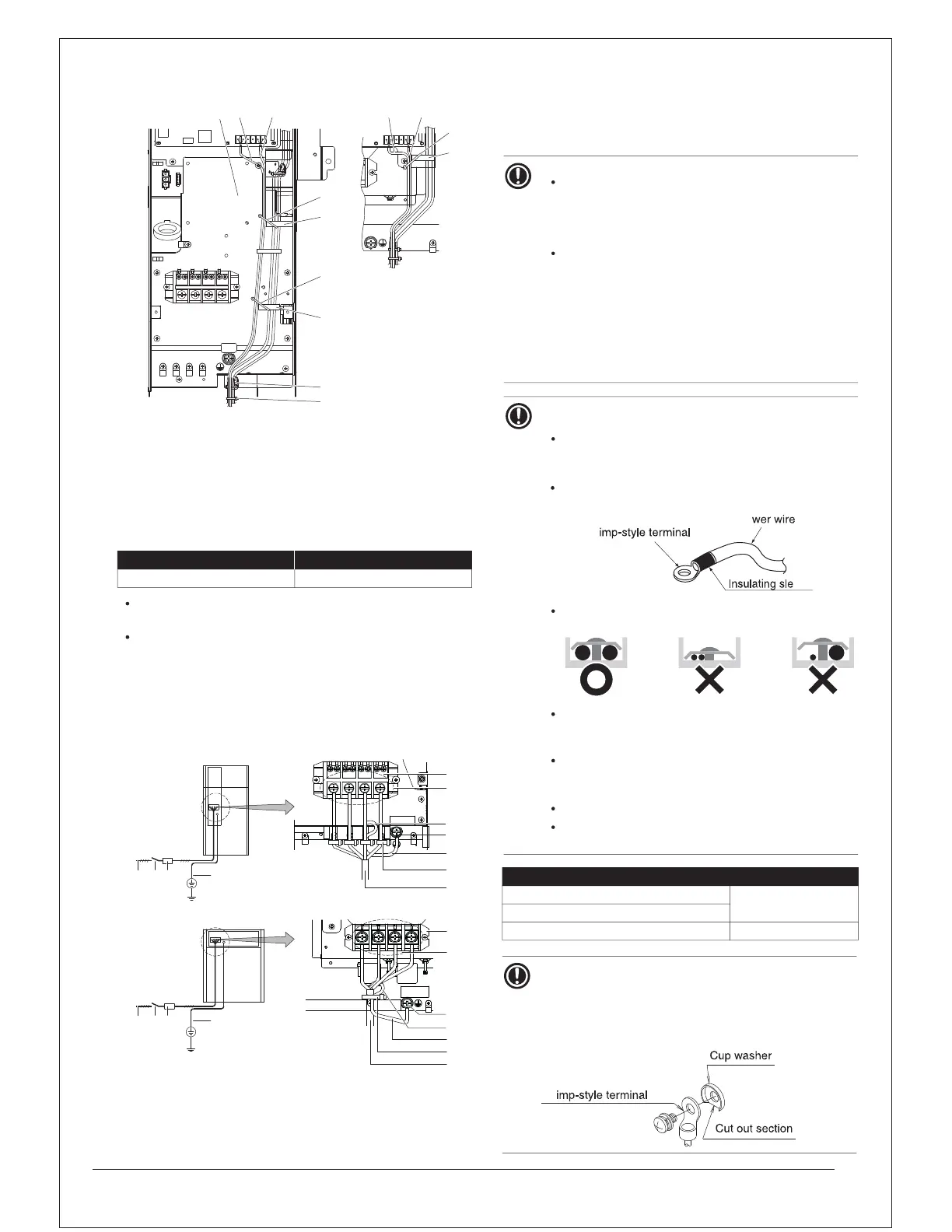

Transmission wiring in outdoor unit

1 Fix to the indicated plastic clamps using field supplied

clamping material

2 Wiring between the units (indoor-outdoor) (F1/F2 left)

3 Internal transmission wiring (Q1/Q2)

4 Plastic clamp

5 Field supplied clamps

Care should be taken for connecting the wires to the terminal block.

See the table below for the tightening torque of the transmission

wiring terminals.

Never connect the power supply to transmission wiring terminal

block. Otherwise the entire system may break down.

Be careful about polarity of the transmission wiring.

Power supply

The power supply must be clamped to the plastic clamp using field

supplied clamp material.

The green and yellow striped wire must be used for earthing only

(refer to the figure below).

1 Power supply (380~415 V - 3N~ 50 Hz / 380 V - 3N~60 Hz)

2 Fuse

3 Earth leakage protector

4 Earth wire

5 Power supply terminal block

6 Connect each power wire: RED to L1, WHT to L2, BLK to

L3 and BLU to N

Screw size Tightening torque (N•m)

0.88±0.08)P1A( 5.3M

L1 L2 L3 N

1

4

5

4

5

5

5

4

4

2 3 2 3

1

23 4

1

23 4

RXQ14~20

RXQ6~12

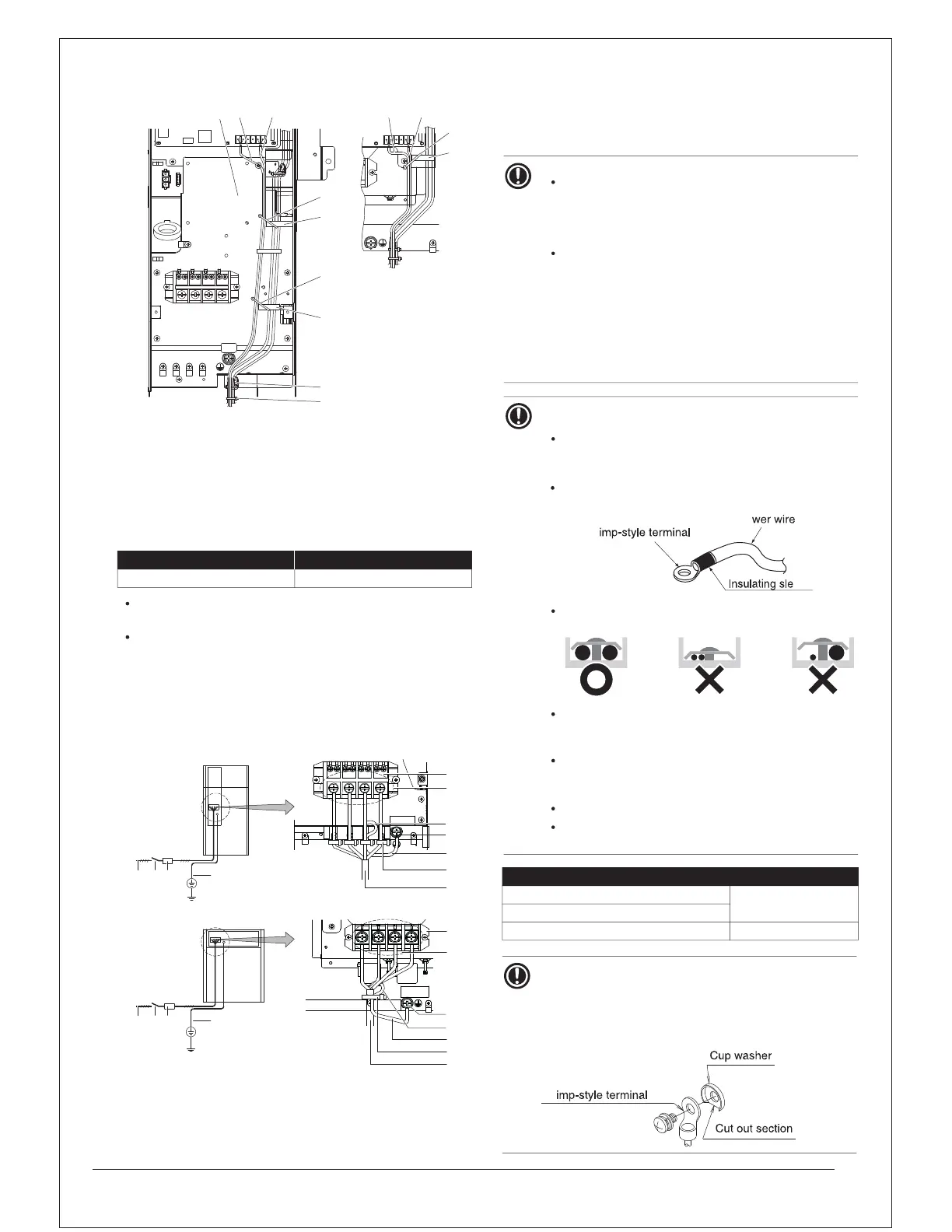

7 Earth wire (GRN/YLW)

8 Clamp the power supply to the plastic clamp using a

tie wrap (1) to prevent external force being applied to

the terminal.

9 Tie wrap (1)

10 Cup washer

11 When connecting the earth wire, it is recommended to

perform curling.

NOTICE

When routing earth wires, secure clearance of 25 mm

or more away from compressor lead wires. Failure to

observe this instruction properly may adversely affect

correct operation of other units connected to the same

earth.

When connecting the power supply, the earth

connection must be made before the current-carrying

connections are established. When disconnecting the

power supply, the current-carrying connections must

be separated before the earth connection is. The length

of the conductors between the power supply stress relief

and the terminal block itself must be as such that the

current-carrying wires are tautened before the earth wire

is in case the power supply is pulled loose from the

stress relief.

NOTICE

Precautions when laying power wiring:

Do not connect wiring of different thicknesses to the

power terminal block (slack in the power wiring may

cause abnormal heat).

When connecting wiring which is the same thickness,

do as shown in the figure below.

For wiring, use the designated power wire and connect

firmly, then secure to prevent outside pressure being

exerted on the terminal board.

Use an appropriate screwdriver for tightening the terminal

screws. A screwdriver with a small head will damage

the head and make proper tightening impossible.

Over-tightening the terminal screws may break them.

See the table below for tightening torque for the

terminal screws.

Tightening torque (N•m)

M8 (Power terminal block)

6.3±0.6

M8 (Ground)

0.88±0.08)kcolb lanimret gniriw tinu-retnI( 3.5M

NOTICE

Recommendations when connecting the earth wire

Wire it so that it comes through the cut out section of the

cup washer. (An improper earth connection may prevent a

good earthing from being achieved.) (See the figure below.)

Be sure to use crimp-style terminal with insulating

sleevesforconnections.(Seethefigurebelow.)

Po

Cr

eve

Cr

6

8

5

10

11

7

9

6

7

5

10

11

8

9

Loading...

Loading...