IM 1044-2 Centrifugal Chillers 45

Maintenance

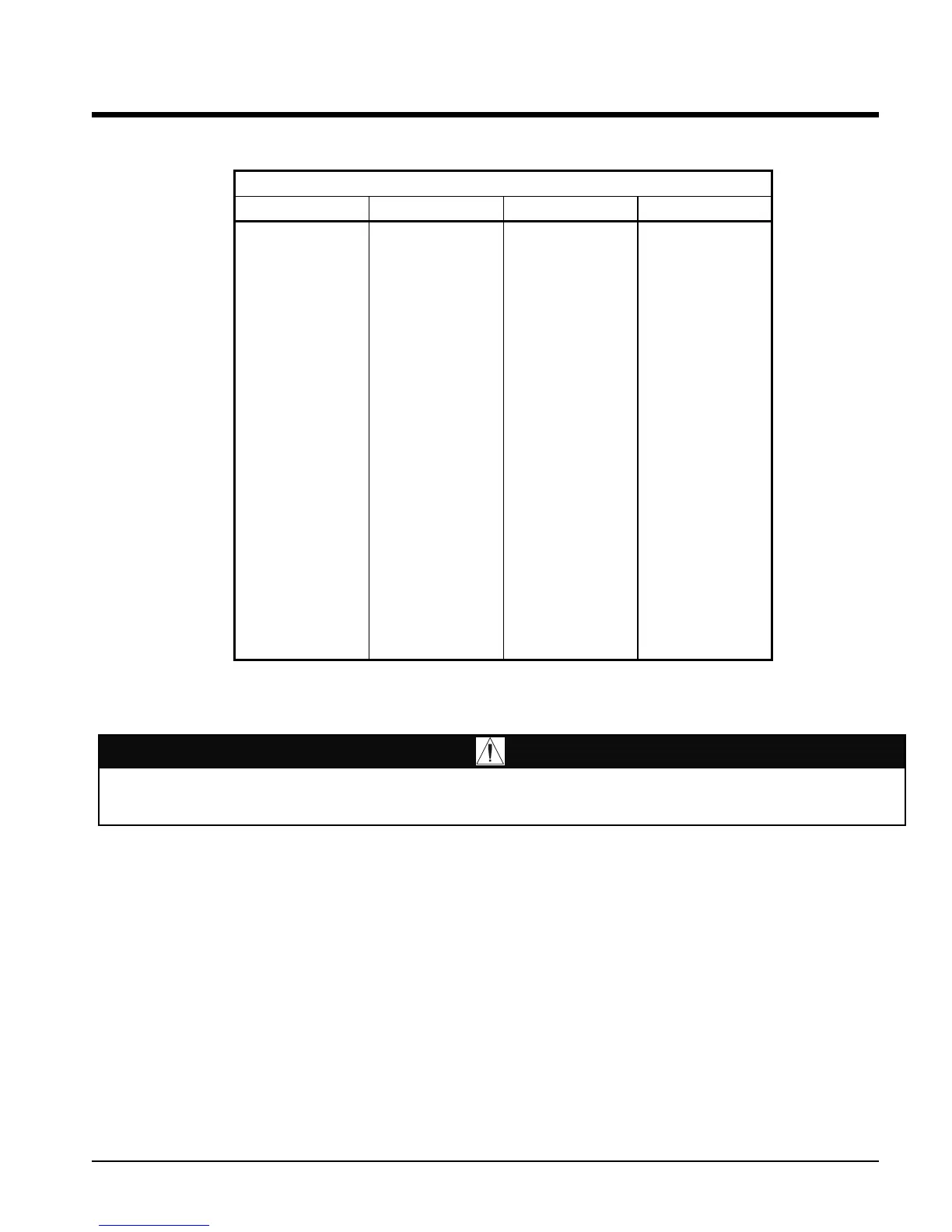

Pressure/Temperature Chart

HFC-134a Temperature Pressure Chart

°F PSIG °F PSIG °F PSIG °F PSIG

6 9.7 46 41.1 86 97.0 126 187.3

8 10.8 48 43.2 88 100.6 128 192.9

10 12.0 50 45.4 90 104.3 130 198.7

12 13.2 52 47.7 92 108.1 132 204.5

14 14.4 54 50.0 94 112.0 134 210.5

16 15.7 56 52.4 96 115.9 136 216.6

18 17.1 58 54.9 98 120.0 138 222.8

20 18.4 60 57.4 100 124.1 140 229.2

22 19.9 62 60.0 102 128.4 142 235.6

24 21.3 64 62.7 104 132.7 144 242.2

26 22.9 66 65.4 106 137.2 146 249.0

28 24.5 68 68.2 108 141.7 148 255.8

30 26.1 70 71.1 110 146.3 150 262.8

32 27.8 72 74.0 112 151.1 152 270.0

34 29.5 74 77.1 114 155.9 154 277.3

36 31.3 76 80.2 116 160.9 156 284.7

38 33.1 78 83.4 118 166.0 158 292.2

40 35.0 80 86.7 120 171.1 160 299.9

42 37.0 82 90.0 122 176.4 162 307.8

44 39.0 84 93.5 124 181.8 164 315.8

Routine Maintenance

Lubrication

CAUTION

Improper servicing of the lubrication system, including the addition of excessive or incorrect oil, substitute quality oil filter,

or any mishandling can damage the equipment. Only authorized and trained service personnel should attempt

this service. For qualified assistance, contact your local Daikin service location.

After the system is once placed into operation, no other additional oil is required except in the event that repair

work becomes necessary to the oil pump, or unless a large amount of oil is lost from the system due to a leak.

If oil must be added with the system under pressure, use a hand pump with its discharge line connected to the

backseat port of the valve in the lubricant drain from the compressor to the sump. See Figure 26 on page 40. The

POE oils used with R-134a are hygoscopic and care must be exercised to avoid exposure to moisture (air).

The condition of compressor oil can be an indication of the general condition of the refrigerant circuit and

compressor wear. An annual oil check by a qualified laboratory is essential for maintaining a high level of

maintenance. It is useful to have an oil analysis at initial startup to provide a benchmark from which to

compare future tests. The local Daikin service office can recommend suitable facilities for performing these

tests.

Table 16 gives the upper limits for metals and moisture in the polyolester lubricants required by Daikin

chillers.

Loading...

Loading...