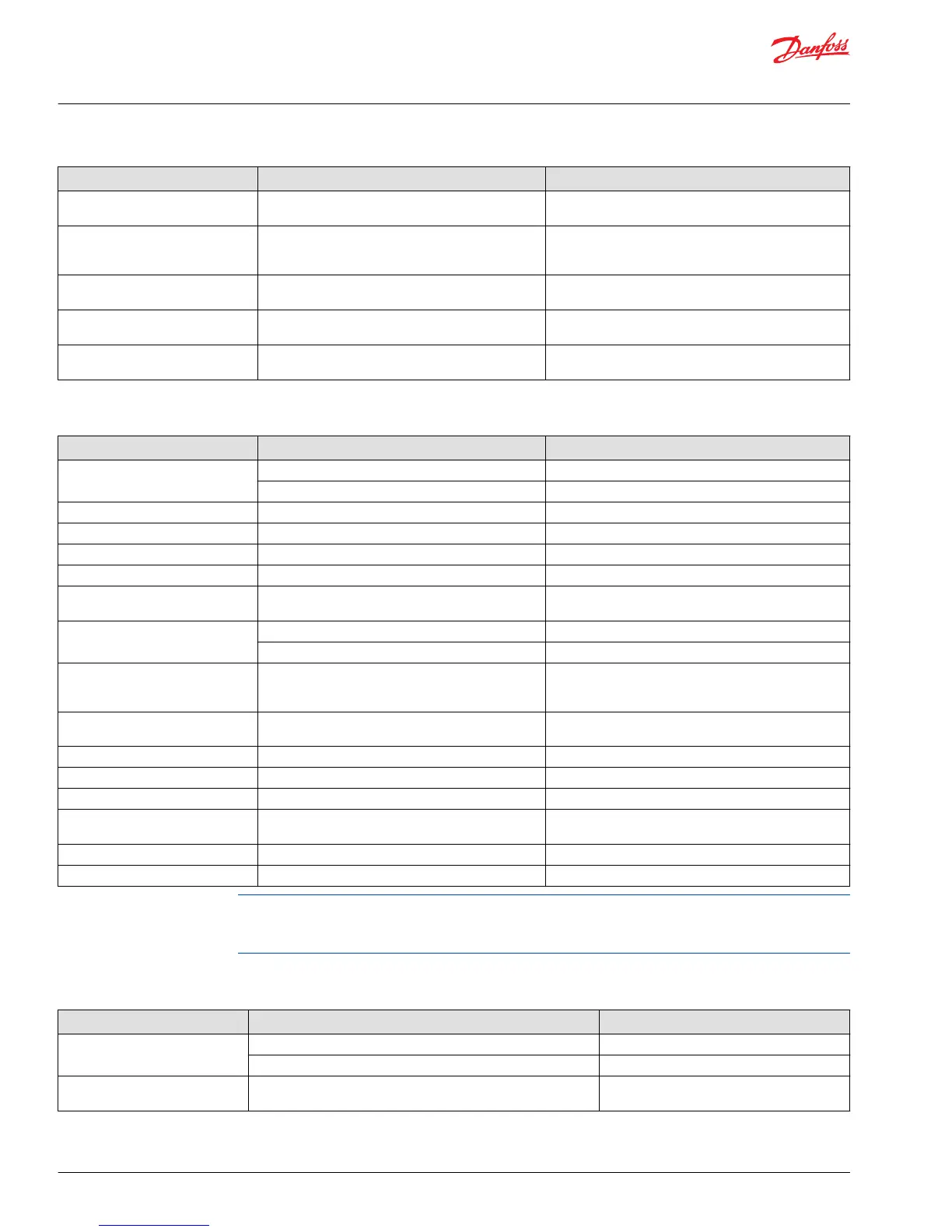

Cause Check Corrective action

Main spool position feedback

transducer signal incorrect

Check feedback pin for damage Replace PVE

Contamination in hydraulic oil Take oil sample Flush complete system.

Fill reservoir with clean filtered fluid per OEM

specification

Air in hydraulic pilot lines Check for air trapped in signal lines from the

controller to the valve section module

Bleed air from the hose connection at the valve section

Hydraulic remote actuator faulty Check signal pressure from the remote hydraulic

controller

Repair or replace cylinder/motor

Low hydraulic oil supply Check fluid level in reservoir Fill reservoir with clean filtered fluid per OEM

specification

Hydraulic oil supply

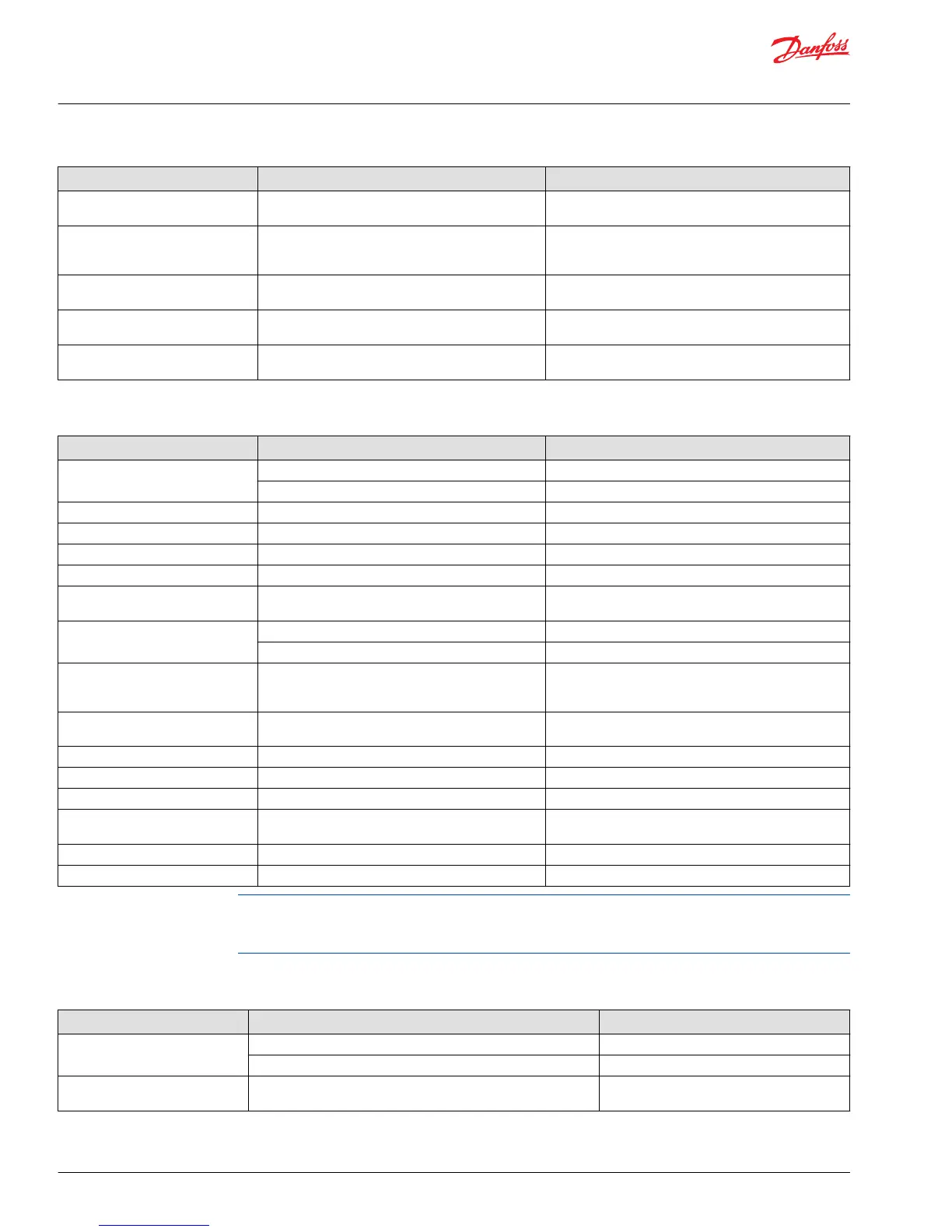

Cause Check Corrective action

Pump not running Check prime mover for operation Repair or replace prime mover

Check condition of drive coupling Repair or replace drive coupling

Insufficient oil in reservoir Check fluid level in reservoir Fill with clean filtered oil

Leaking or burst supply hose Inspect lines to valve stack Repair or replace damaged hose

Relief valve malfunction Check for contamination and operation of relief valve Repair or replace relief valve

Isolating valves are closed Check that all isolating valves are open and clear

Faulty pump control Check pump compensator for correct operation and

setting per pump manufacturers

Repair or replace pump compensator per pump

manufacturers recommendations

Low standby pressure in PVP - open

center pump

Check idle standby pressure - 10 Bar [145 PSI] Replace

Check condition of compensator spool spring Replace module due to worn components

Low standby pressure in pump

control - variable pump

Check pump LS control for operation and setting

Stand by pressure should be 15 bar [220 psi]

minimum

Repair or replace LS control per pump manufacturers

procedures

PVP pressure relief valve faulty Check pressure relief valve spool and spring for

freedom of operation

Replace

PVP orifices blocked Check PVP orifices for blockage Remove blockage

Internal filters blocked Check for blockage in internal filters Remove blockage

Supply lines blocked Inspect supply lines for blockages Remove blockage

Internal hydraulic pilot pressure

insufficient

Inspect pilot oil pressure reducing valve for proper

operation

Repair or replace

Blocked LS galleries Check LS galleries for blockage Clean blockage from LS galleries

Shuttle valves faulty Check LS system shuttle valves for wear and damage Replace as needed

Check for contamination per specification HPP 030. Refer to Design Guideline for Hydraulic Fluid

Cleanliness, Technical Information Manual 520L0467. If fluid is out of spec., flush hydraulic system and fill

with clean filtered oil.

Electrical supply

Cause Check Corrective action

No electrical power Check electrical circuit Repair as needed

Verify emergency stop switch is in the proper operating position Reset

Neutral position switch faulty Check operation of neutral position switch in remote controller (if

connected in circuit) PVRE/PVRES/PVREL

Replace switch

Service Manual

PVG 32 Proportional Valve Group

System Troubleshooting

18 |

©

Danfoss | February 2017 11039167 | AX00000031en-US0301

Loading...

Loading...