MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT

®

2000 Series

22

Saved energy

Energy is saved when the motor runs at a speed

which is continually matched to the momentary

requirement. An example is a pump and ventilating

plant, where a frequency converter can reduce energy

consumption by the cube of the speed.

Improved process

Matching the speed to the production process has

several advantages: an increase in production and a

decrease in the consumption of materials and the

scrapping rate.

Improved quality

The number of starts and stops is reduced. This avoids

unnecessarily hard treatment of machine parts.

Less maintenance

The frequency converter requires no maintenance.

In water supply plants there are no pressure surges

which might damage the water pipes.

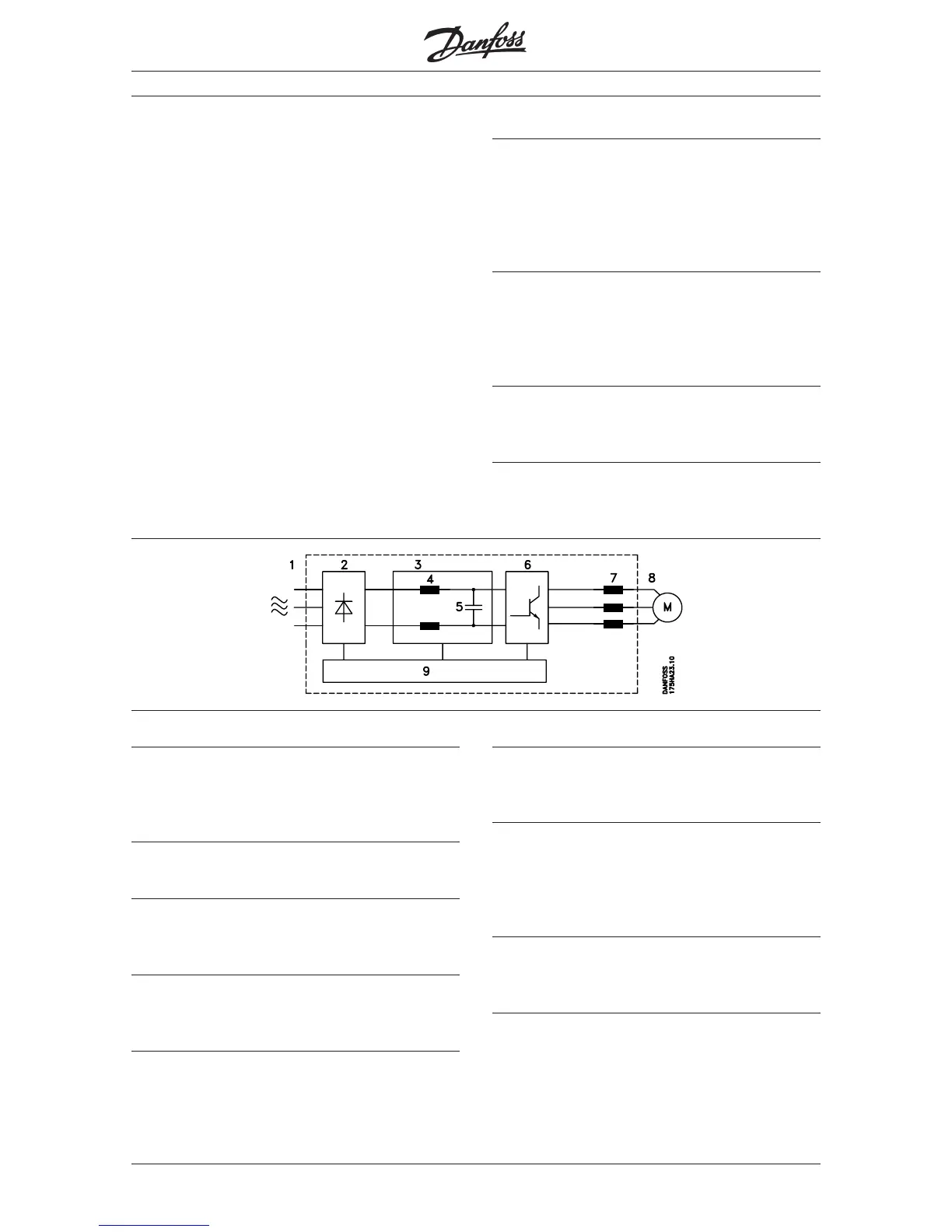

1. Mains supply

1 × 220/230/240 V AC, 50/60 Hz

3 × 208/220/230/240 V AC, 50/60 Hz

3 × 380/400/415/440/460 V AC, 50/60 Hz

2. Rectifier

Three-phase rectifier bridge rectifies AC to DC.

3. Intermediate circuit

DC voltage = √2 × supply voltage

4. Coils in the intermediate circuit

(not all VLT 2000 units)

Smoothen DC voltage and limit mains

supply interference (mains harmonics).

5. Capacitors in the intermediate circuit

Smoothen the voltage of the intermediate circuit

(energy store).

6. Inverter

Converts DC voltage to variable a.c.voltage and

variable frequency.

7. Motor coils (as module)

Advantages of motor coils:

− You can use long motor cables.

− Unlimited switching at the output of

the frequency converter (trip may occur).

8. Output

Variable a.c. voltage,10-100% of the supply voltage.

Variable frequency: 0-120/0-500 Hz.

9. Control card

The integrated computer controls the inverter, which

generates the pulse pattern by means of which DC

voltage is converted to variable a.c. voltage and

variable frequency.

How the VLT works

How the VLT is built up

A frequency converter is an electronic unit for infinite

speed control of a.c. motors. The frequency converter

controls the motor speed by converting the fixed volt-

age and frequency of the supply mains, e.g. 400 V/

50 Hz, to variable values. The frequency converter

does this by rectifying a.c. voltage to DCvoltage and

converting this to a.c. voltage with variable amplitude

and frequency.

The variable voltage and frequency supplying the motor

make infinite speed control of standard three-phase,

asynchronous motors possible.Today the a.c. motor

controlled by a frequency converter is a natural part of

all automised plants. Apart from utitilizing the good fea-

tures of the a.c. motor, the infinite speed control gives

the user a multitude of additional advantages:

■■

■■

■

Loading...

Loading...