VLT

®

5000 Series

Installation

■ Electrical installation

The voltage on the frequency converter is

dangerous when the unit is connected to

mains. Incorrect installation of the motor or

the frequency converter may lead to material damage

or serious injury or it may be fatal. Consequently, the

instructions in this manual as well as national and local

rules and safety regulations must be complied with.

Touching the electrical parts may be fatal, even after

the mains supply has been disconnected.

Using VLT 5001-5006, 200-240 V and 380-500

V: wait at least 4 minutes.

Using VLT 5008-5052, 200-240 V: wait

at least 15 minutes.

Using VLT 5008-5062, 380-500 V: wait

at least 15 minutes.

Using VLT 5072-5302, 380-500 V: wait

at least 20 minutes.

Using VLT 5352-5552, 380-500 V: wait

at least 40 minutes.

Using VLT 5001-5005, 525-600 V: wait

at least 4 minutes.

Using VLT 5006-5022, 525-600 V: wait

at least 15 minutes.

Using VLT 5027-5062, 525-600 V: wait

at least 30 minutes.

Using VLT 5042-5352, 525-690 V: wait

at least 20 minutes.

Using VLT 5402-5602, 525-690 V: wait

at least 30 minutes.

NB!:

It is the user’s or certified electrician’s

responsibility to ensure correct earthing and

protection in accordance with applicable

national and local norms and standards.

■ High voltage test

A high voltage test can be carried out by short-

circuiting terminals U, V, W, L

1

,L

2

and L

3

and

energizing by max. 2.15 kV DC for one second

between this short-circuit and the chassis.

NB!:

The RFI switch must be closed (position

ON)whenhighvoltagetestsarecarried

out (see section RFI Switch).

The mains and motor connection must be interrupted

in the case of high voltage tests of the total installation

if the leakage currents are too high.

■ Safety earthing

NB!:

The frequency converter has a high leakage

current and must be earthed appropriately

for safety reasons. Use earth terminal

(see section Electrical installation, power cables),

which enables reinforced earthing.

Apply national safety regulations.

■ Extra protection (RCD)

ELCB relays, multiple protective earthing or earthing

can be used as extra protection, provided that local

safety regulations are complied with.

In the case of an earth fault, a DC content may

develop in the faulty current.

If ELCB relays are used, local regulations must be

observed. Relays must be suitable for protection

of 3-phase equipment with a bridge rectifier and

for a brief discharge on power-up.

See also the section Special Conditions in

the Design Guide.

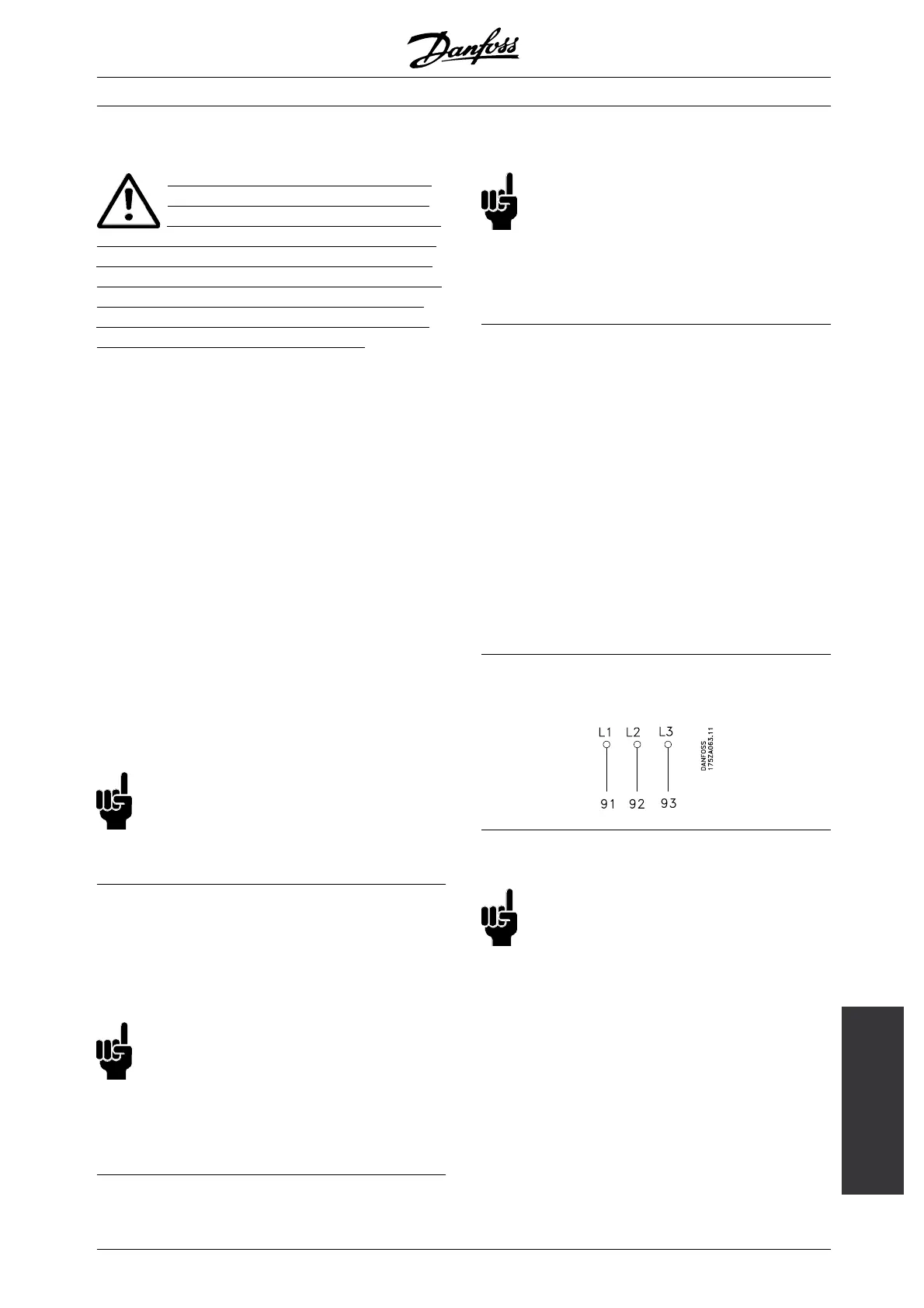

■ Electrical installation - mains supply

Connect the three mains phases to terminals L

1

,L

2

,L

3

.

■ Electrical installation - motor cables

NB!:

If an unscreened cable is used, some

EMC requirements are not complied with,

see the Design Guide.

If the EMC specifications regarding emission are

to be complied with, the motor cable must be

screened, unless otherwise stated for the RFI filter

in question. It is important to keep the motor cable

as short as possible so as to reduce the noise level

and leakage currents to a minimum.

The motor cable screen must be connected to the

metal cabinet of the frequency converter and to the

metal cabinet of the motor. The screen connections

are to be made with the biggest possible surface

(cable clamp). This is enabled by different installation

devices in the different frequency converters.

MG.51.A9.02 - VLT is a registered Danfoss trademark

43

Loading...

Loading...