VLT

®

5000 Series

Special

functions

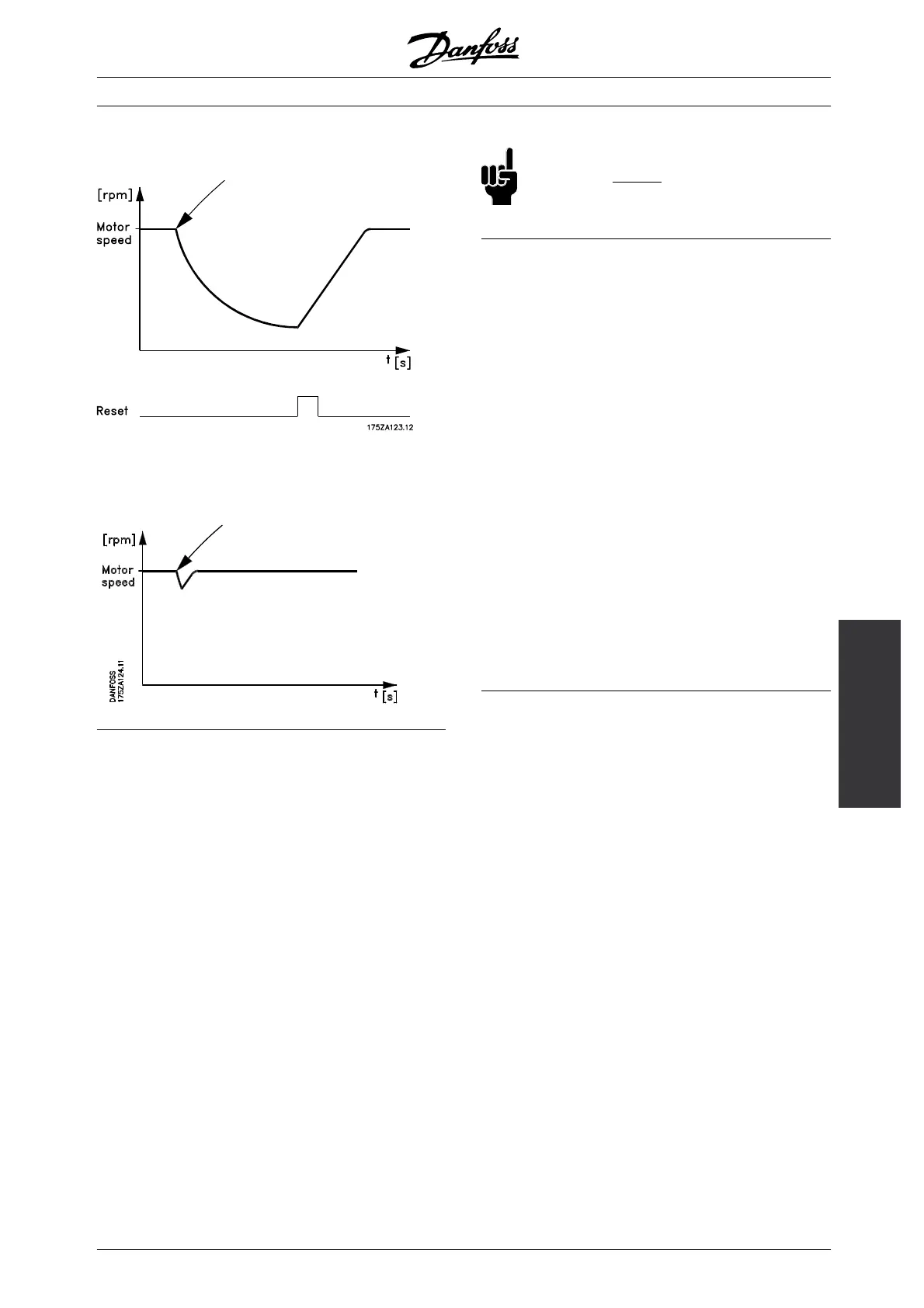

3. The frequency converter trips and Flying

start is active.

4. The frequency converter momentarily

releases the motor. Flying start is activated

and catches the motor again.

■ Normal/high overload torque control,open loop

This function enables the frequency converter to perform

a constant 100% torque, using an oversize motor.

The choice between a normal or a high overload torque

characteristic is made in parameter 101.

Thisisalsowheretochoosebetweenahigh/normal

constant torque characteristic (CT) or a high/normal

VT torque characteristic

If a high torque characteristic is chosen, a rated

motor with the frequency converter obtains up to

160% torque for 1 min. in both CT and VT. If a

normal torque characteristic is chosen, an oversize

motor allows up to 110% torque performance for up

to 1 min. in both CT and VT. This function is used

mainly for pumps and fans, since these applications

do not require an overload torque.

The advantage of choosing a normal torque

characteristic for an oversize motor is that the frequency

converter will be able constantly to yield 100% torque,

without derating as a result of a bigger motor.

NB!:

This function c

annot be chosen for VLT

5001-5006, 200-240 Volts, and VLT

5001-5011, 380-500 Volts.

■ Internal current regulator

The VLT 5000 features an integral current limit

regulator which is activated when the motor current,

and thus the torque, is higher than the torque

limits set in parameter 221 and 222.

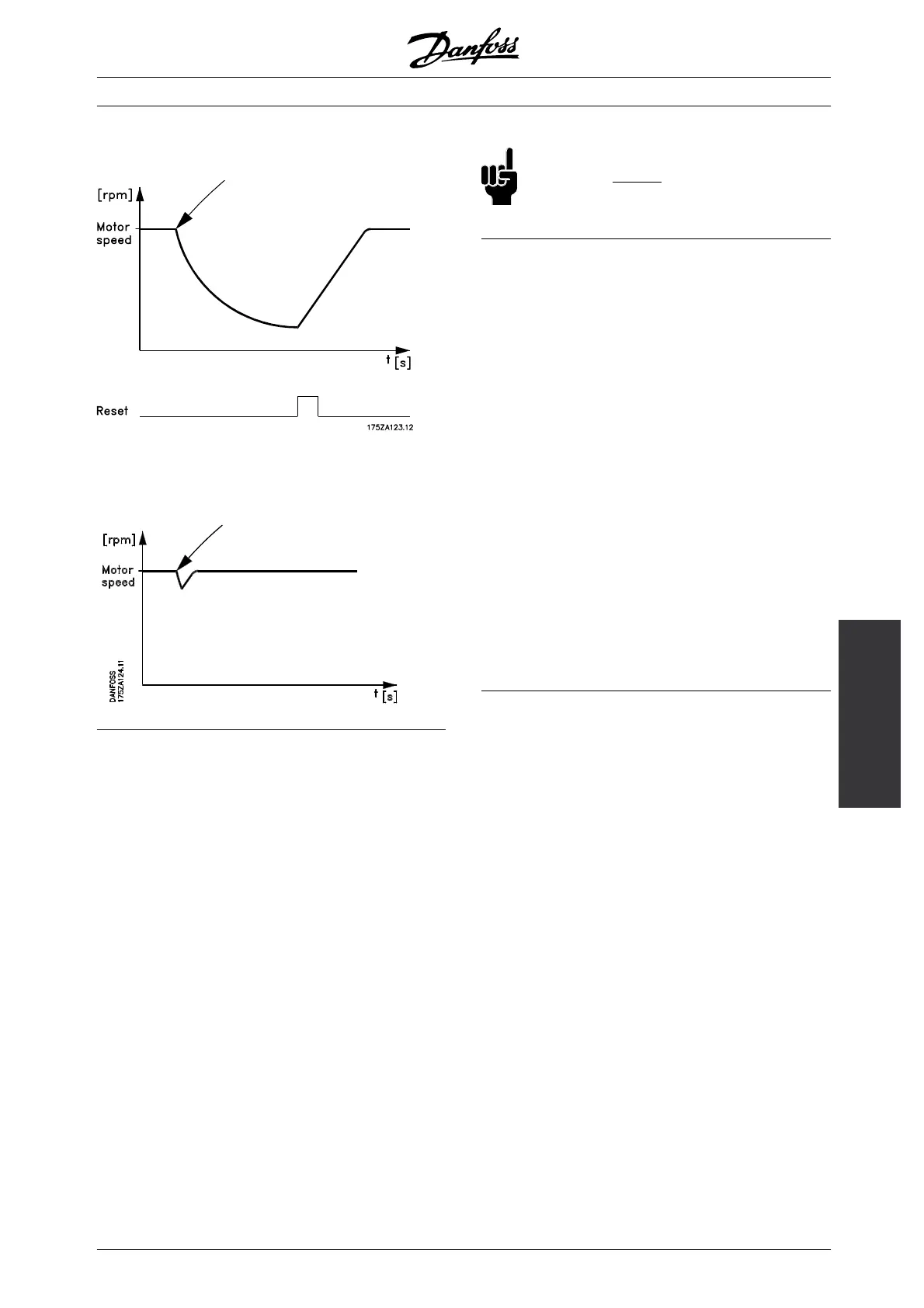

When VLT 5000 Series is at the current limit

during motor operation or regenerative operation,

the frequency converter will try to get below the

preset torque limits as quickly as possible without

losing control of the motor.

While the current regulator is active, the frequency

converter can only be stopped by means of terminal

27 if set to Coasting stop, inverse [0] or Reset and

coasting stop, inverse [1]. A signal on terminals

16-33 will not be active until the frequency converter

has moved away from the current limit.

Please note that the motor will not use the

ramp-down time, since terminal 27 must be

programmed for Coasting stop, inverse [0] or

Reset and coasting stop, inverse [1].

■ Programming of Torque limit and stop

In applications with an external electro-mechanical

brake, such as hoisting applications, it is possible

to stop the frequency converter via a ‘standard’

stop command, while at the same time activating

the external electro-mechanical brake.

The example given below illustrates the programming

of frequency converter connections.

The external brake can be connected to relay 01 or

04, see Control of mechanical brake on page 66.

Program terminal 27 to Coasting stop, inverse [0]

or Reset and coasting stop, inverse [1], as well as

terminal 42 to Torque limit and stop [27].

MG.51.A9.02 - VLT is a registered Danfoss trademark

95

Loading...

Loading...