VLT

®

5000 Series

Application

configuration

Select Process control, closed loop if the application

has a feedback signal that is not directly related to

motor speed (rpm/Hz), but units, such as temperature,

pressure, etc. Typical applications are pumps and fans.

Set the following parameters in the order shown:

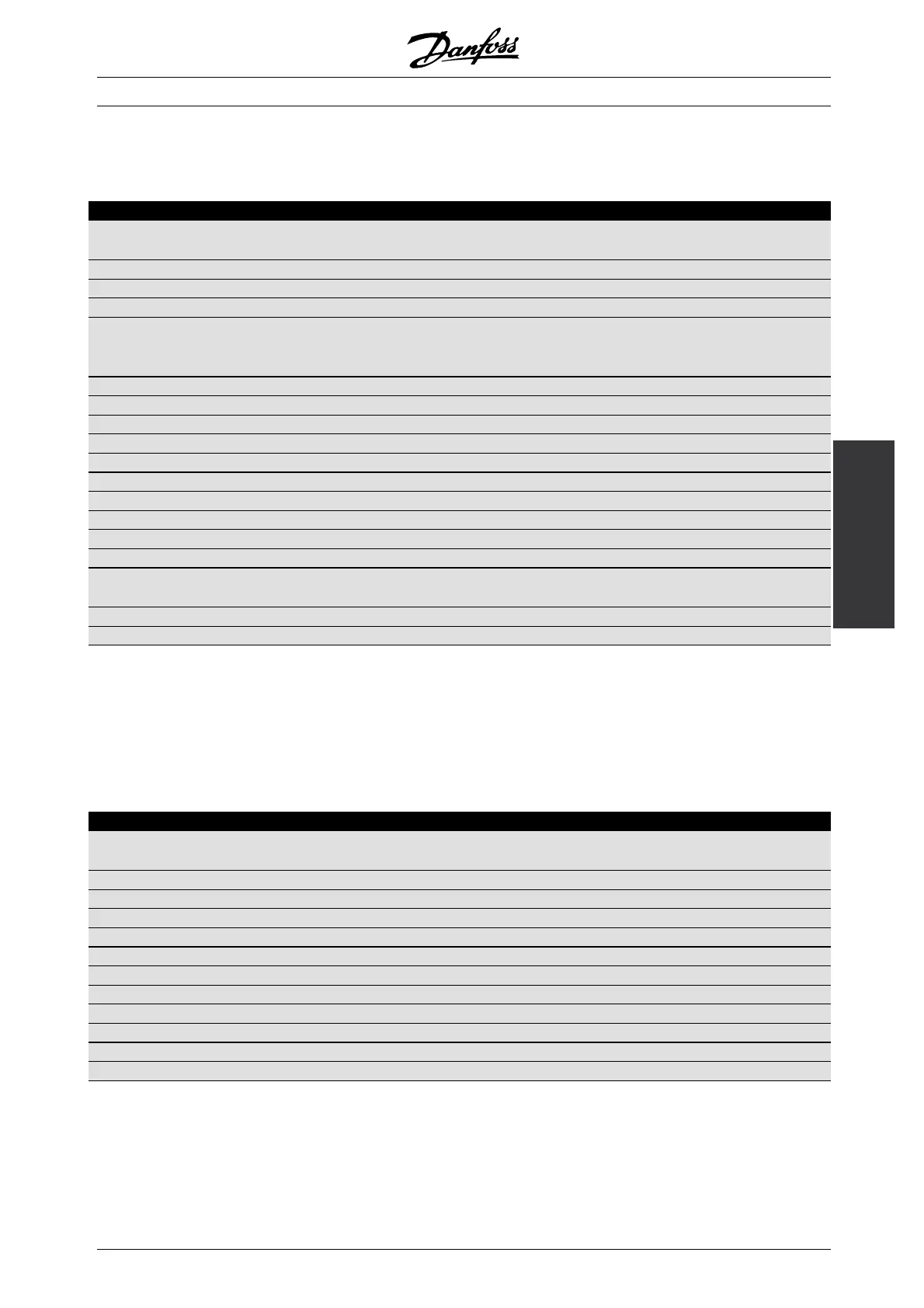

Process control, closed loop (Process PID):

Parame-

ter:

Setting: Data value:

100 Configuration Process control, closed loop [3]

201 Output frequency low limit

202 Output frequency high limit

416 Process units Define the feedback and reference

input as described in the section

PID for process control.

203 Reference/feedback range

204 Minimum reference Only if [0] in par. 203

205 Maximum reference

414 Minimum feedback

415 Maximum feedback

437 Process PID normal/inverse

438 Process PID anti-windup

439 Process PID start frequency

440 Process PID proportional gain

441 Process PID integration time

442 Process PID differentiation time Only used in high dynamic

applications

443 Process PID diff. gain limit

444 Process PID lowpass filter

Select Torque control, open loop if PI control is

required, to change the motor frequency in order

to maintain the torque ref

erence (Nm).

This is relevant for winding and extrusion applications.

Torque control, open loop, is to be selected if the

speed direction is not to be changed during operation;

this means that either a positive or a negative

torque reference is used at all times.

Set the following parameters in order shown:

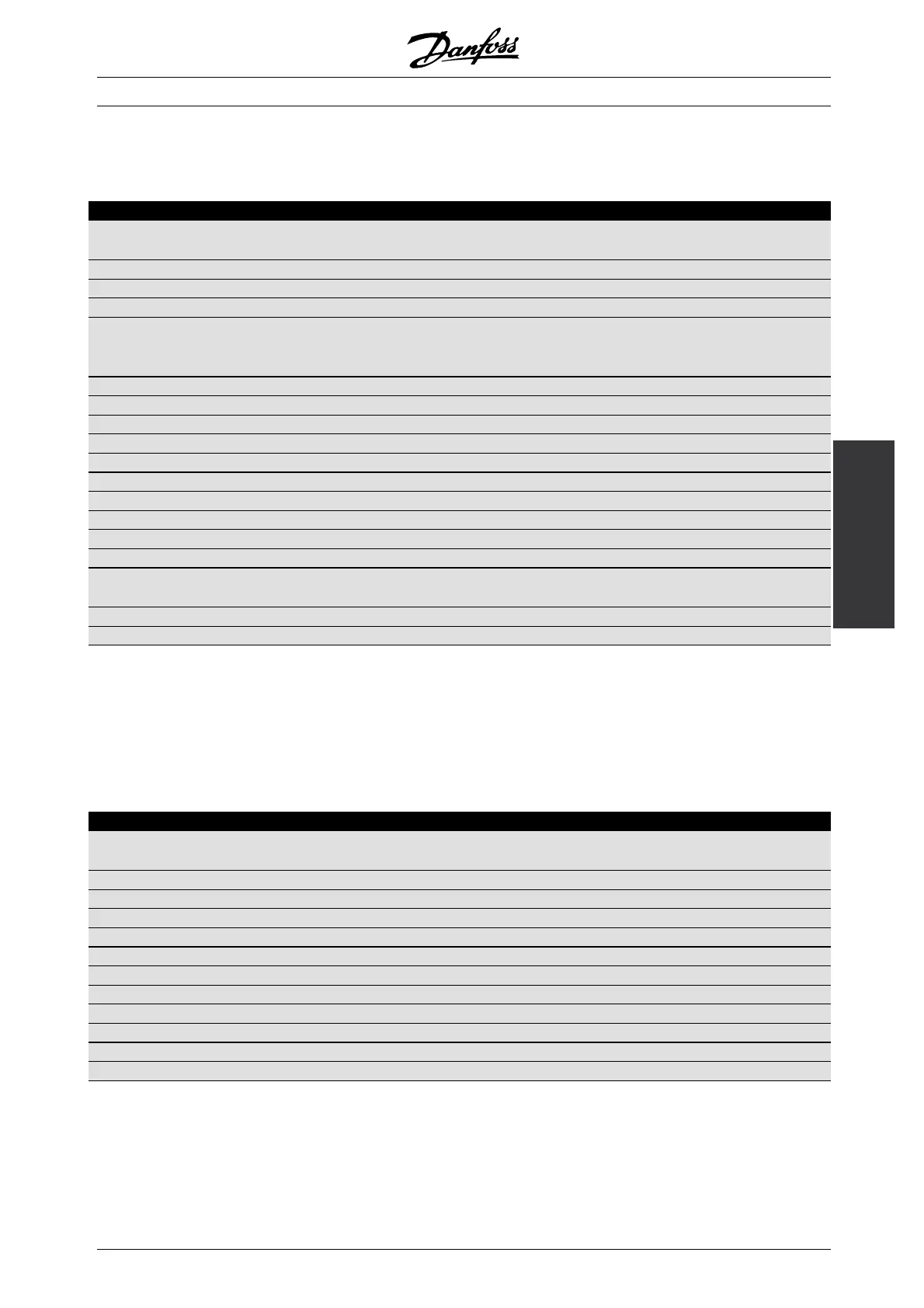

Torque control, open loop:

Parame-

ter:

Setting: Data value:

100 Configuration Torque control, open loop [4]

200 Output frequency range/direction

201 Output frequency low limit

202 Output frequency high limit

203 Reference/feedback range

204 Minimum reference Only if [0] in par. 203

205 Maximum reference

414 Minimum feedback

415 Maximum feedback

433 Torque proportional gain

434 Torque integration time

Select Torque control, speed feedback,ifanencoder

feedback signal is to be generated. This is relevant

in winder and extruder applications.

MG.51.A9.02 - VLT is a registered Danfoss trademark

77

Loading...

Loading...